Silicon-carbon composite material, preparation method and application as well as lithium ion battery negative electrode material

A technology of silicon-carbon composite materials and lithium-ion batteries, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as battery performance degradation, and achieve the effect of improving cycle life and avoiding detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

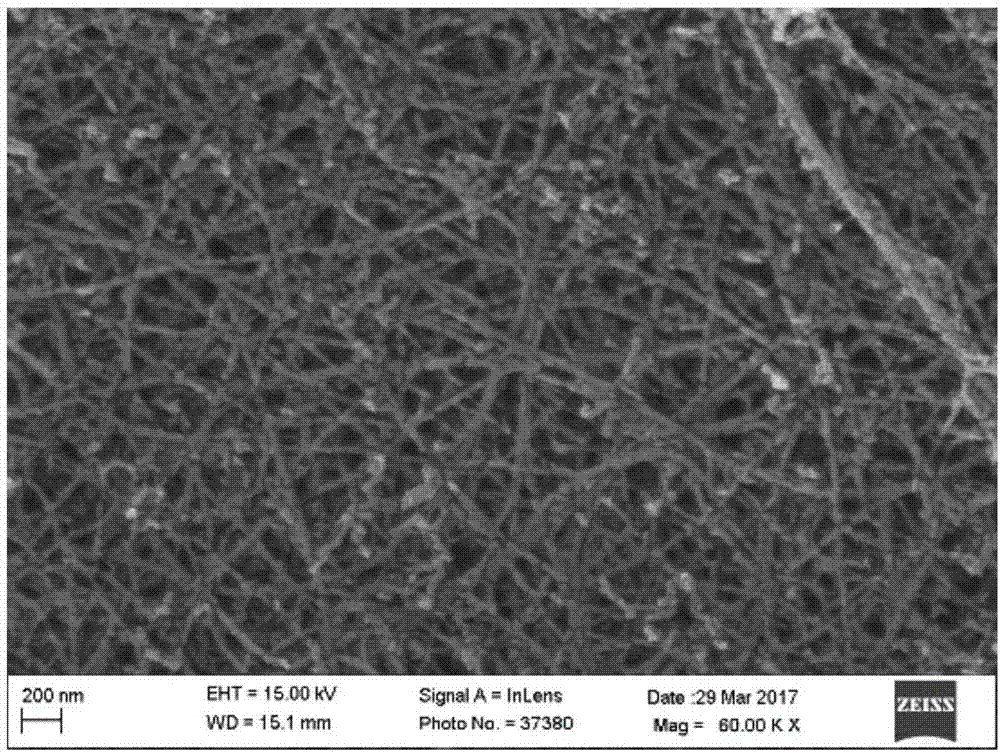

[0078] As a preferred embodiment of the present invention, the preparation method of the above-mentioned silicon-carbon composite material includes the following steps:

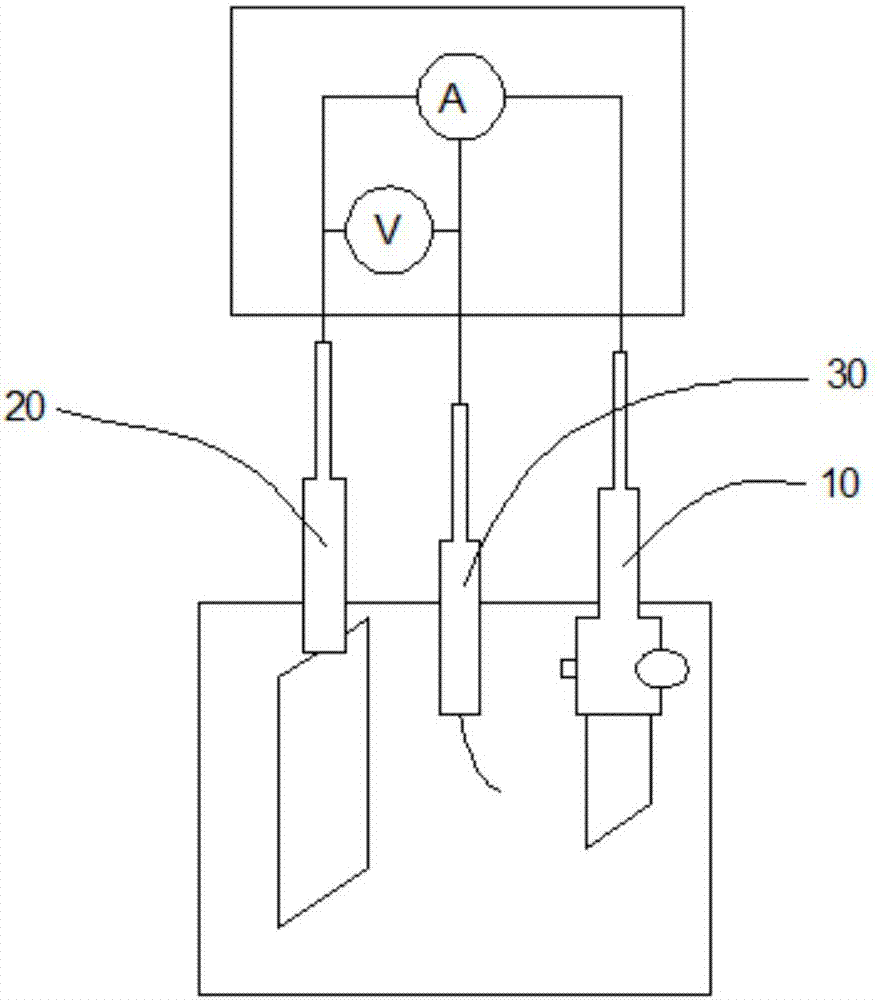

[0079] The three-dimensional carbon material is placed as a working electrode in an electroplating solution containing a silicon source, and a three-electrode system is used for electrodeposition in an environment of protective gas to obtain a silicon film on the surface of the three-dimensional carbon material.

[0080] As a preferred embodiment of the present invention, the protective gas in the above method for preparing the silicon-carbon composite material is argon or nitrogen. The use of inert gas protection such as protective argon or nitrogen can prevent the oxidation-reduction reaction of the electroplating solution during the electrodeposition process, avoid the reaction of the silicon source with water and oxygen, and reduce the utilization rate of the electroplating solution.

[0081] As a preferr...

Embodiment approach

[0092] As a preferred embodiment of the present invention, the electrodeposition method includes any one of constant current method, constant voltage method, square wave current method, square wave voltage method or cyclic voltammetry or a combination of at least two methods.

[0093] As a preferred embodiment of the present invention, in the electrodeposition process, the current density is -0.1~-10mA / cm 2 , The voltage range is -1.5~-3.5V, and different current and voltage values are selected according to the concentration of the silicon source in the electroplating solution to improve the electrodeposition effect.

[0094] As a preferred embodiment of the present invention, the counter electrode in the three-electrode system includes a platinum sheet electrode or a titanium sheet electrode. Optionally, the reference electrode in the three-electrode system includes a platinum wire electrode, silver silver chloride electrode, calomel electrode, mercury oxide mercury electro...

Embodiment 1

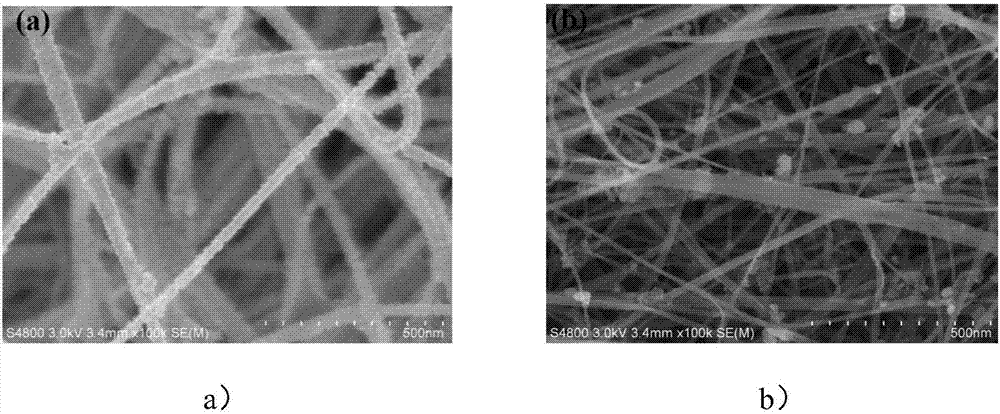

[0099] This embodiment is a method for preparing a silicon-carbon composite material. The three-dimensional carbon material in this embodiment uses three-dimensional carbon nanotube paper, which includes the following steps:

[0100] Step a): Cut out 18×10mm 2 The three-dimensional carbon nanotube paper was ultrasonically cleaned with deionized water and absolute ethanol for 15 minutes, and then vacuum-dried at 60°C for 12 hours in a vacuum drying oven;

[0101] Step b): In order to further improve the conductivity of the three-dimensional carbon nanotube paper, a thin layer of gold is steamed on the surface of the three-dimensional carbon nanotube paper to form a gold layer. The specific operation includes the following steps: vacuum-drying the three-dimensional carbon nanotube paper Place the nanotube paper in a film steaming machine, steam gold at 200°C, the current is 210A, and the duration is 15min; then take out the carbon nanotube paper, replace one side and repeat the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com