Method for preparing graphene oxide grafting surface modification carbon fiber

A technology of surface modification and carbon fiber, which is applied in the direction of carbon fiber, chemical instruments and methods, fiber treatment, etc., can solve the problems of reduced interlayer shear strength of composite materials, poor wettability of resin matrix, and reduced surface tension, etc., reaching the price Low cost, improved roughness, and improved interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

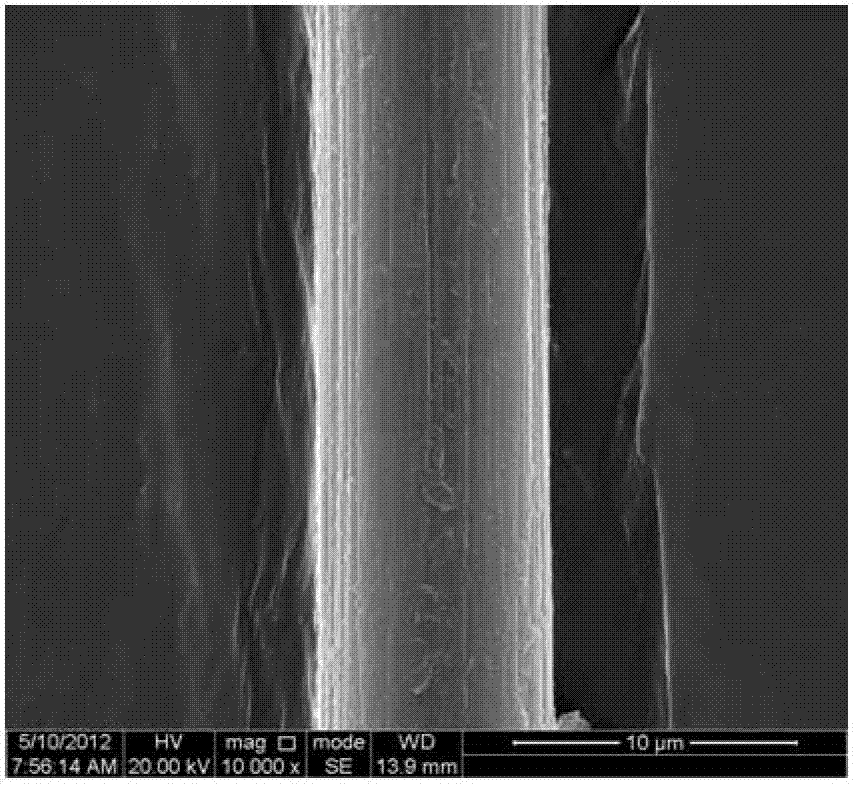

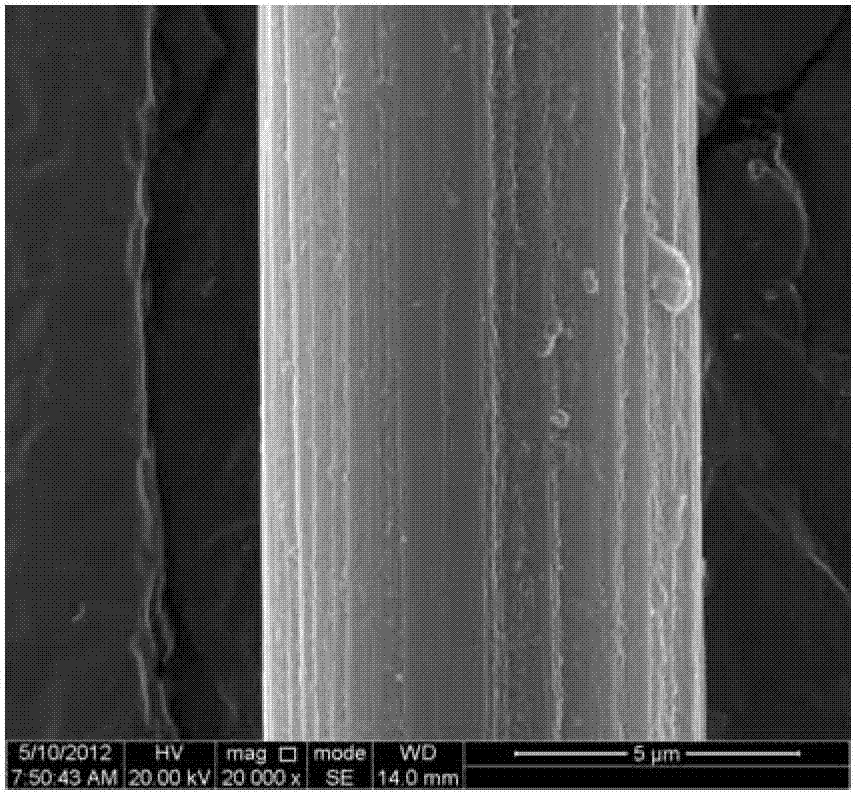

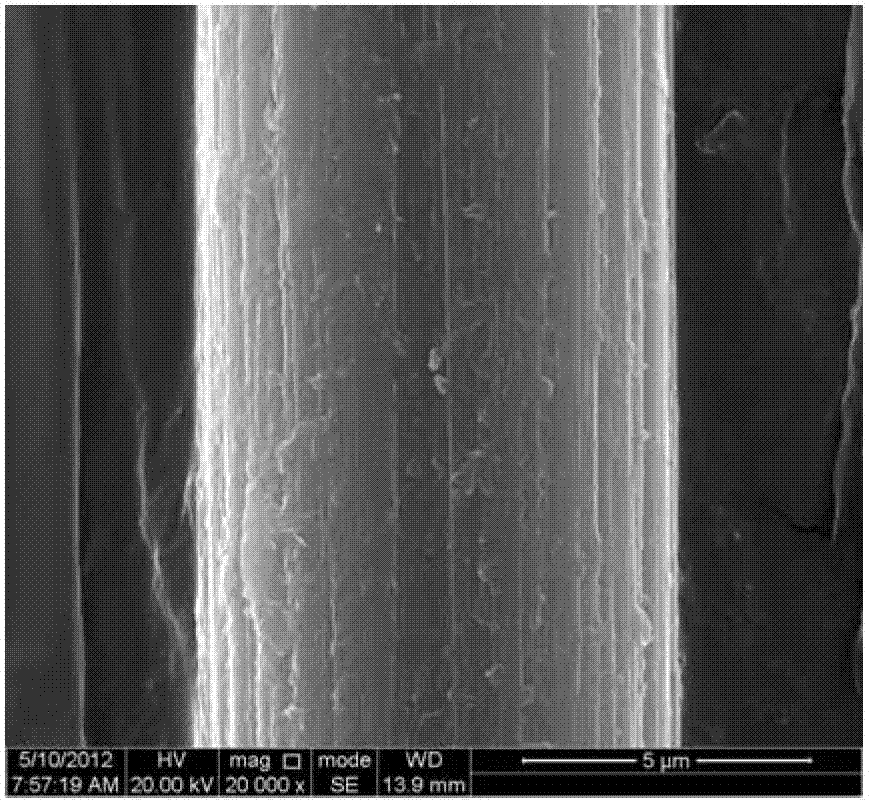

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the method for grafting surface modified carbon fiber of graphene oxide in this embodiment is carried out according to the following steps:

[0026] 1. Graphite oxidation:

[0027] Add graphite into the mixture of strong oxidizing acid and nitrate, cool to -5°C~0°C, stir and add potassium-containing strong oxidant at a speed of 50rpm~200rpm, and continue stirring for 4h~12h to obtain a mixed solution. Pour the solution into a water bath at 10°C to 50°C, continue to react for 40min to 60min, then add hot water at 90°C to 100°C, make the system boil and keep it for 20min to 40min, then add hydrogen peroxide solution with a volume concentration of 40% to 60%. , stirred at a speed of 100rpm to 500rpm until completely dissolved, then washed with ultrapure water for 3 to 6 times, and filtered until there was no SO in the filter cake 4 2- , and then freeze-dried at -35°C to obtain graphite oxide;

[0028] Wherein the mass ratio of graphite and stron...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment differs from Embodiment 1 in that the strong oxidizing acid described in step 1 is concentrated sulfuric acid or perchloric acid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the potassium-containing strong oxidizing agent described in step one is potassium permanganate or potassium perchlorate. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com