Combined electrode for flow battery and flow energy storage battery

A liquid flow energy storage battery and composite electrode technology, which is applied to battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of limited improvement in voltage efficiency and energy efficiency, and achieve lower ohmic internal resistance, lower body resistance, The effect of simple electrode structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

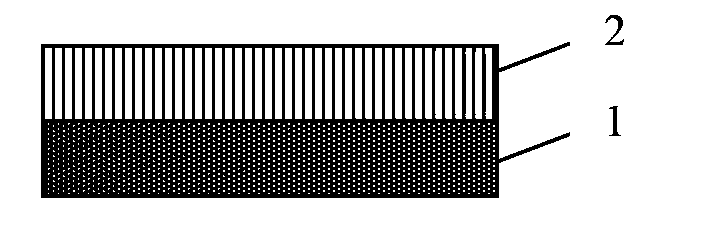

[0033] The conductive layer of the electrode is a non-porous graphite plate with a thickness of 2mm and a bulk density of 2.0gcm -3 ; The catalytic layer is made of carbon felt with a thickness of 3mm and a bulk density of 0.14gcm -3 ; The electrode adopts a non-integrated method, that is, the conductive layer and the catalytic layer are used independently.

[0034] When assembling the battery, according to the end plate, sealing gasket, current collector plate (bipolar plate), sealing gasket, electrode frame, sealing gasket, conductive layer, catalytic layer, membrane, catalytic layer, conductive layer, sealing gasket, The electrode frame, sealing gasket, current collector plate (bipolar plate), sealing gasket, and end plate are assembled together in sequence, and then assembled into an all-vanadium redox flow single cell under the compression of the end plate. Wherein, in the electrode frame, the side of the bipolar plate is a conductive layer, and the side of the membrane ...

Embodiment 2

[0041] The conductive layer of the electrode is a flexible graphite plate with a thickness of 3mm and a bulk density of 1.0gcm -3 , the porosity is 50%; the catalytic layer is carbon felt, 3mm thick, and the bulk density is 0.14gcm -3 ; The electrode adopts a non-integrated method, that is, the conductive layer and the catalytic layer are used independently.

[0042] When assembling the battery, according to the end plate, sealing gasket, current collector plate (bipolar plate), sealing gasket, electrode frame, sealing gasket, conductive layer, catalytic layer, membrane, catalytic layer, conductive layer, sealing gasket, Electrode frame, sealing gasket, current collecting plate (bipolar plate), sealing gasket, electrode frame, sealing gasket…the sequence of current collecting plate (bipolar plate), sealing gasket and end plate assembles each component in Together, and then assembled into an all-vanadium redox flow battery pack under the compression of the end plates. Wherein...

Embodiment 3

[0045] The conductive layer of the electrode is graphite felt with a thickness of 3mm and a bulk density of 0.4gcm -3 ; The catalytic layer is made of carbon felt with a thickness of 2mm and a bulk density of 0.14gcm -3 ; The electrode adopts a non-integrated method, that is, the conductive layer and the catalytic layer are used independently.

[0046] When assembling the battery, according to the end plate, sealing gasket, current collector plate (bipolar plate), sealing gasket, electrode frame, sealing gasket, conductive layer, catalytic layer, membrane, catalytic layer, conductive layer, sealing gasket, The electrode frame, sealing gasket, current collector plate (bipolar plate), sealing gasket, and end plate are assembled together in sequence, and then assembled into an all-vanadium redox flow single cell under the compression of the end plate. Wherein, in the electrode frame, the side of the bipolar plate is a conductive layer, and the side of the membrane is a catalytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com