Carbon sulfur composite material for lithium-sulfur battery and preparation method and application for carbon sulfur composite material

A composite material, lithium-sulfur battery technology, applied in the field of electrochemical batteries, can solve the problems of active material loss, active material content reduction, increase inactive materials, etc., to achieve high electrolyte absorption capacity, high specific energy density, good conductivity network effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] After the bacterial cellulose was fully washed in deionized water, it was quickly frozen with liquid nitrogen, and then placed in a vacuum oven at -50°C and 20.0 Pa to remove all moisture. Subsequently, the obtained bacterial cellulose aerogel was placed in an atmosphere tube furnace and heated at 5 °C min under the protection of Ar gas. -1 The heating rate was increased to 800°C for high-temperature carbonization, and after 1 hour of heat preservation, it was cooled with the furnace to prepare carbonized bacterial cellulose.

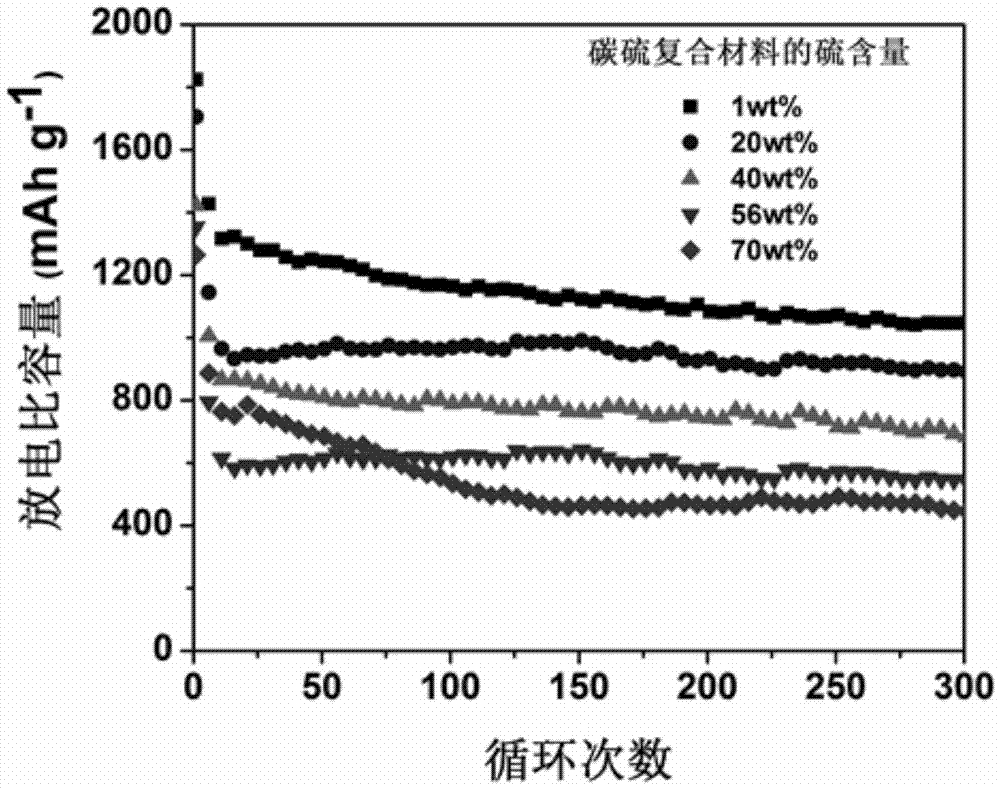

[0038] Dissolve different masses of Huahua sulfur in the carbon disulfide solution to prepare the concentrations of 20 mg·mL -1 , 15mg·mL -1 , 8mg·mL -1 , 5mg·mL -1 and 0.5mg·mL -1 solution of sulfur in carbon disulfide. Immerse the carbonized bacterial cellulose in solutions of different concentrations, take it out after soaking for 1 hour, dry it in a fume hood, place it in an oven, keep it at a constant temperature of 155°C for 12 hours, ...

Embodiment 2

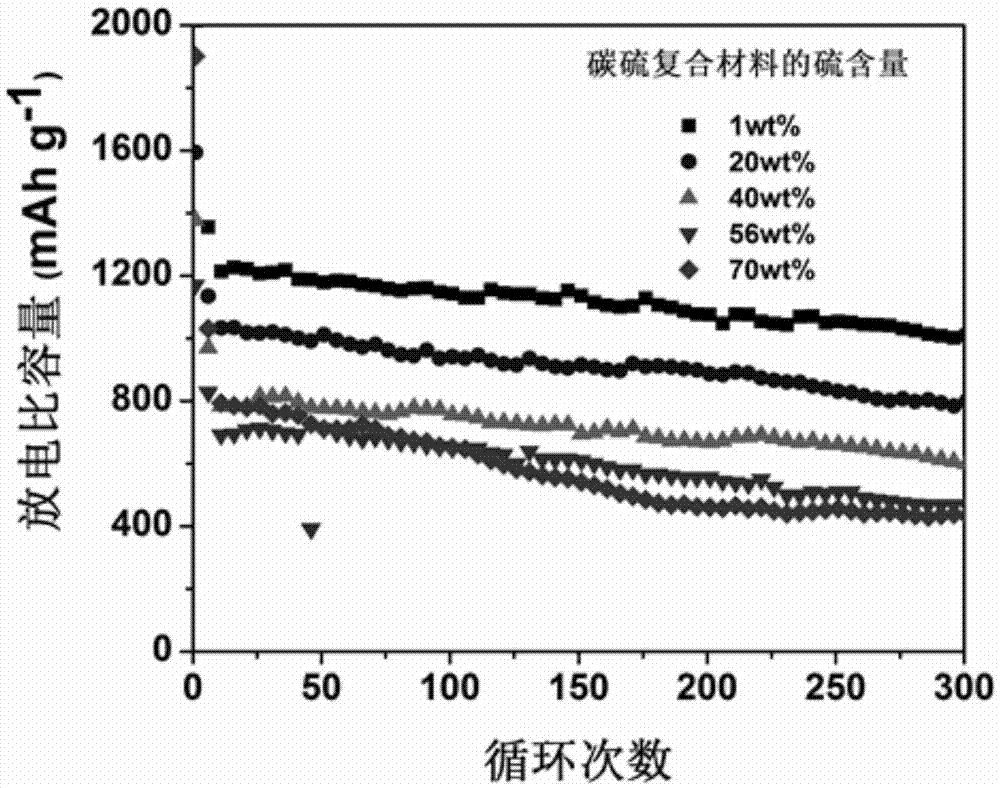

[0041] 1 g of lignocellulose was dispersed in 100 mL of an aqueous solution of TEMPO (0.016 g) and NaBr (0.016 g). Another part of 12 wt% NaClO aqueous solution was prepared, and HCl solution was added to adjust its pH value to 10. A certain amount of NaClO solution was added to the lignocellulose dispersion so that the ratio of NaClO to cellulose was 3 mmol NaClO: 1 g cellulose. The resulting solution was stirred at room temperature and the pH was controlled at 10 with NaOH solution. TEMPO-mediated cellulose oxidation ends when NaOH is no longer consumed. Subsequently, the oxidized cellulose was washed with deionized water through suction filtration, and then dispersed in water. The oxidized cellulose dispersion is subjected to vacuum filtration to prepare a lignocellulose film. The obtained lignocellulose film was placed in an atmosphere tube furnace at 5 °C min under the protection of Ar gas. -1 The heating rate was increased to 800°C for high-temperature carbonization,...

Embodiment 3

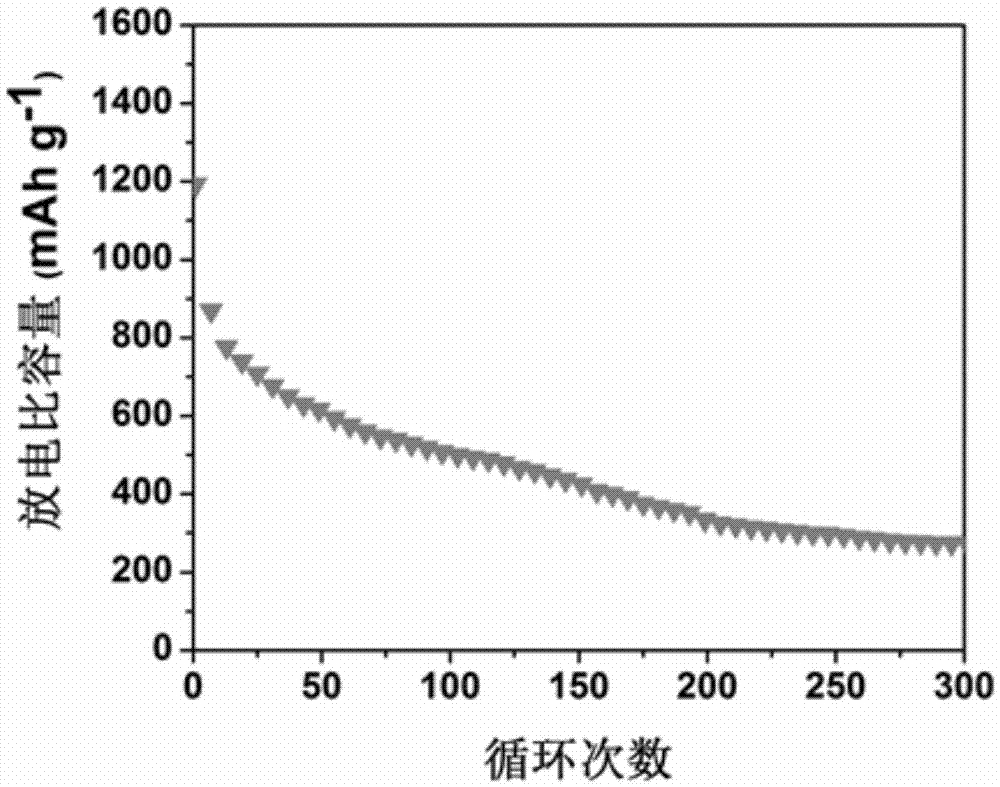

[0045] The multi-walled carbon nanotubes were added into an aqueous solution with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1, and oxidized by heating and refluxing at 80° C. for 12 hours. Subsequently, the suspension is diluted with deionized water and centrifugally cleaned, and the final product is ultrasonically dispersed in a certain amount of deionized water to obtain a carbon nanotube dispersion.

[0046] Sodium sulfide (Na 2 S) be dissolved in deionized water, after forming a solution, add sublimation sulfur, control Na 2 The molar ratio of S to sublimed sulfur was 1:3, and stirred at room temperature for 2 h. Subsequently, slowly add acetic acid (CH 3 COOH) to pH=3, the reaction generates sulfur particle precipitation. After the precipitate was taken out by centrifugation, it was washed three times with deionized water and dispersed by ultrasonic to obtain a sulfur suspension.

[0047]The carbon nanotube dispersion and the sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com