Zinc-cobalt sulfide/carbon nano negative electrode material and preparation method thereof

A negative electrode material and sulfide technology, which is applied in the field of zinc-cobalt sulfide/carbon nano-negative electrode material and its preparation, can solve the problems that the rate performance needs to be improved, the preparation process is complicated and cumbersome, and the particle size and crystal form are not easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

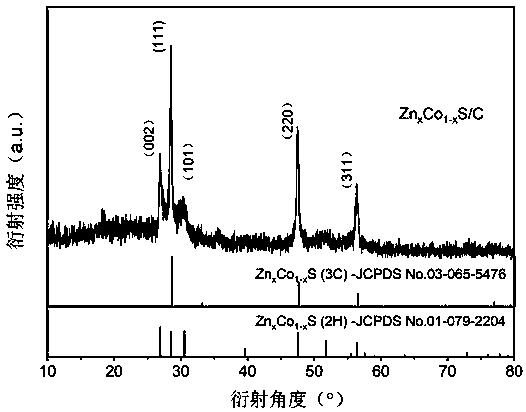

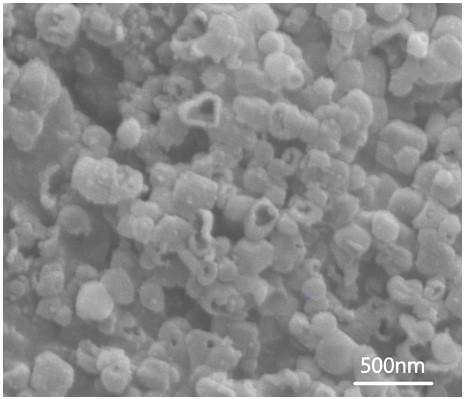

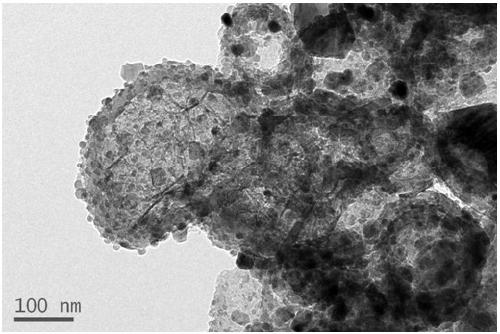

[0072] The zinc-cobalt sulfide / carbon nano-anode material is that zinc-cobalt sulfide nanoparticles are distributed inside and on the surface of the carbon matrix as irregular polyhedrons with a particle size of 10-30 nm, and the formed particle size is 100-250 nm, and the shell thickness is 20 nm. ~30nm hollow irregular spherical shell structure; the mass ratio of the zinc-cobalt sulfide to carbon is 2.5:1; the chemical formula of the zinc-cobalt sulfide is Zn 0.76 co 0.24 S.

[0073] Such as figure 1 Shown, the characteristic peak shape and intensity of zinc cobalt sulfide / carbon nano negative electrode material of the present invention and Zn x co 1-x The S standard spectrum line is consistent, the peak shape is sharp, and the crystallinity is good, which is the pure phase of zinc-cobalt sulfide; there is a weak and gentle diffraction peak at about 20°, indicating that there is amorphous carbon in the material.

[0074] Such as figure 2 As shown, the zinc-cobalt sulfi...

Embodiment 2

[0088] The zinc-cobalt sulfide / carbon nano-anode material is that zinc-cobalt sulfide nanoparticles are distributed inside and on the surface of the carbon matrix as irregular polyhedrons with a particle size of 20-30 nm, and the formed particle size is 200-300 nm, and the shell thickness is 20 nm. ~40nm hollow irregular spherical shell structure; the mass ratio of the zinc-cobalt sulfide to carbon is 4:1; the chemical formula of the zinc-cobalt sulfide is Zn 0.5 co 0..5 S.

[0089] After testing, the characteristic peak shape and intensity of the zinc-cobalt sulfide / carbon nano negative electrode material of the present invention and Zn x co 1-x The S standard spectrum line is consistent, the peak shape is sharp, and the crystallinity is good, which is the pure phase of zinc-cobalt sulfide; there is a weak and gentle diffraction peak at about 20°, indicating that there is amorphous carbon in the material.

[0090] Such as Figure 8 As shown, the zinc-cobalt sulfide / carbon...

Embodiment 3

[0104] The zinc-cobalt sulfide / carbon nano-anode material is zinc-cobalt sulfide nanoparticles distributed inside and on the surface of the carbon matrix as irregular polyhedrons with a particle size of 10-30 nm, and the formed particle size is 100-300 nm, and the shell thickness is 20 nm. ~50nm hollow irregular spherical shell structure; the mass ratio of the zinc-cobalt sulfide to carbon is 1.5:1; the chemical formula of the zinc-cobalt sulfide is Zn 0.5 co 0.5 S.

[0105] After testing, the characteristic peak shape and intensity of the zinc-cobalt sulfide / carbon nano negative electrode material of the present invention and Zn x co 1-x The S standard spectrum line is consistent, the peak shape is sharp, and the crystallinity is good, which is the pure phase of zinc-cobalt sulfide; there is a weak and gentle diffraction peak at about 20°, indicating that there is amorphous carbon in the material.

[0106] After testing, the zinc-cobalt sulfide / carbon nanometer negative el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com