Method for preparing lead-carbon battery cathode composite material

A composite material, lead-carbon battery technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of battery operation interruption, affecting the conductivity of negative electrode active materials, increasing interface ohmic resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific steps are:

[0018] 1. A method for preparing lead-carbon battery negative electrode composite material, characterized in that the specific steps are:

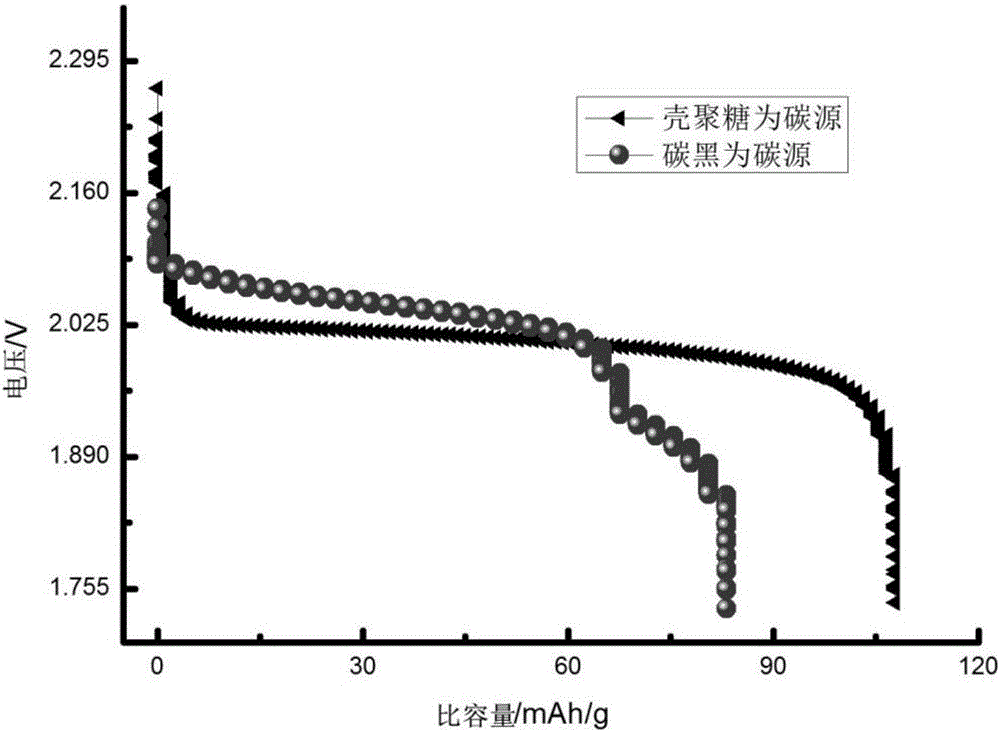

[0019] (1) Take 2 grams of chitosan, soak it in 2% acetic acid solution for 1 hour, then take it out and dry it in an oven at 85° C. for 5 hours, take it out and cool it, and then grind it into powder.

[0020] (2) weigh the chitosan processed in PbO, step (1) in the ratio of 76% by the mass ratio of the sum of PbO and PbO and chitosan, fully grind and mix, prepare sample, put into crucible, place Put it into a muffle furnace, heat under nitrogen protection, heat up to 800°C at a heating rate of 5°C / min, keep it warm for 2 hours, and cool naturally to room temperature to obtain chitosan in situ synthetic carbon material.

[0021] (3) the chitosan in situ synthetic carbon material obtained in step (2) is mixed with the negative electrode active material, and the negative electrode active material is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com