Soil solidifying agent

A technology of soil curing agent and curing agent, which is applied in the fields of soil protection, construction, and infrastructure engineering. It can solve problems such as difficult compliance, poor early strength, and large shrinkage, and achieve improved engineering performance, low cost, and high cost performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

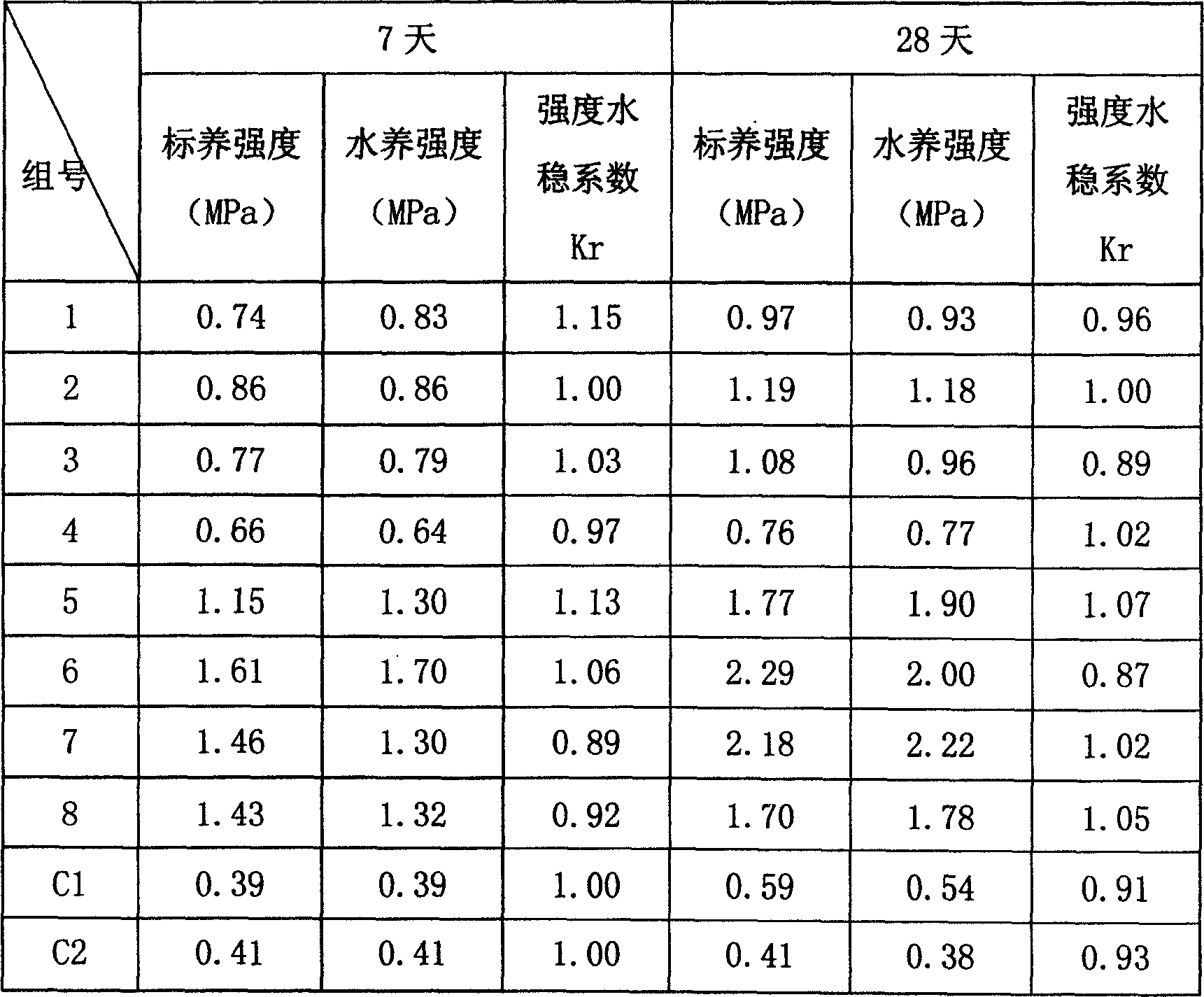

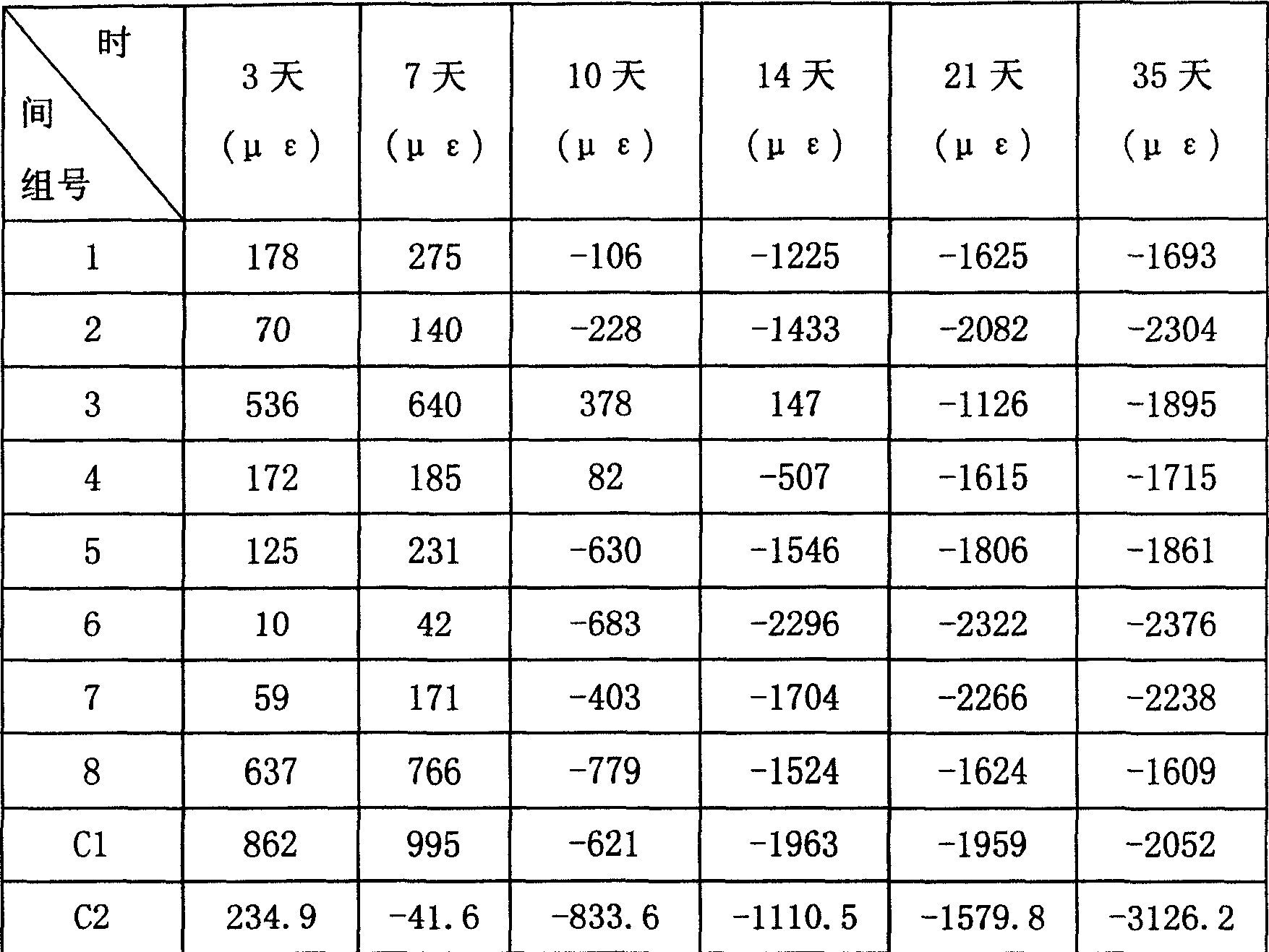

Examples

example 1

[0018] The properties of the main raw materials used are as follows:

[0019] The soil is silt, and its performance indicators are shown in Table 1.

[0020] density

(g / cm 3 )

optimal moisture content

(g / cm 3 )

plasticity index

(I P )

cosmid containing

quantity

Powder content

2.55

14.4%

1.79

6.8%

6.8%

88.3%

[0021] The cement is P.II.52.5 cement from Jingyang Cement Plant. The chemical composition and mineral composition of the clinker are shown in Table 2.

[0022] chemical composition(%)

SiO 2

al 2 o 3

Fe 2 o 3

CaO

MgO

SO 3

quantity

C 3 S

C 2 S

C 3 A

C 4 AF

22.12

5.41

3.34

65.67

1.31

0.53

0.20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com