Clean environment-friendly diesel oil and preparation method thereof

A clean, environmentally friendly, diesel technology, applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve the problems of reducing the temperature of the fuel-air mixture and insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

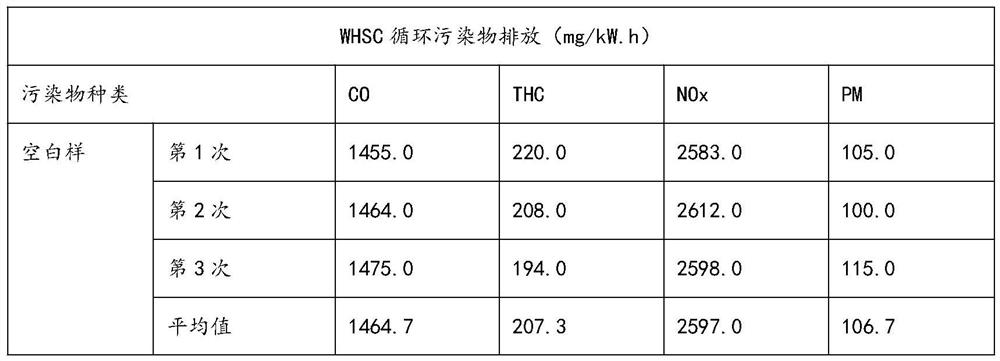

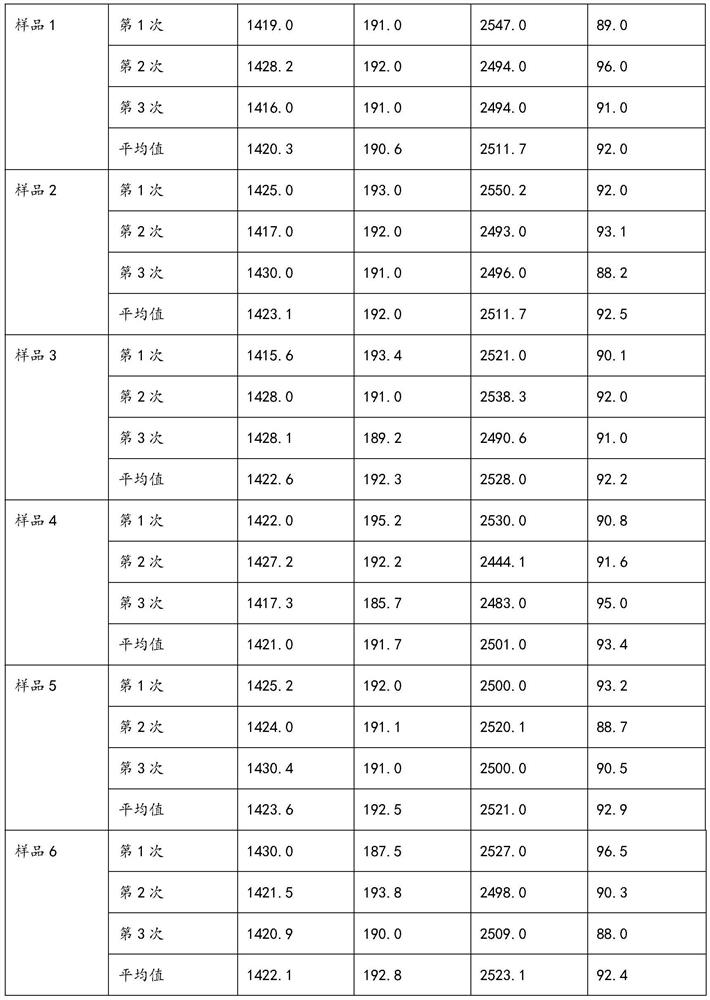

Examples

Embodiment 1

[0048] A clean and environment-friendly diesel oil comprises 92wt% diesel oil and 8wt% liquid nano-detergent. Wherein, the raw material components of the liquid nano-detergent are in parts by weight: 6 parts of base oil, 0.07 parts of isooctyl nitrate, 0.35 parts of polyoxymethylene dimethyl ether, 0.03 parts of modifier, and 1.2 parts of isooctyl alcohol. Wherein, the modifier is a mixture of nonylphenol polyoxyethylene ether-3 (OP-3), Mannich base and dipentyl iron in a mass ratio of 11:1:2.5.

[0049] The preparation method of above-mentioned clean environment-friendly diesel oil comprises:

[0050] Preparation of environmentally friendly detergents:

[0051] Preparation of mixed system A': Take three-fifths of the base oil mass in the raw material as carrier A, add all the isooctyl alcohol in the raw material components to carrier A, use a water bath with a temperature of 15-20 ° C, and simultaneously ultrasonically The way of vibration (frequency is 150-180KHz) makes th...

Embodiment 2

[0057] A clean and environment-friendly diesel oil comprises 92wt% diesel oil and 8wt% liquid nano-detergent. Wherein, the raw material components of the liquid nano-detergent are calculated by weight: 6 parts of base oil, 0.07 parts of isooctyl nitrate, 0.35 parts of polyoxymethylene dimethyl ether, 0.05 parts of modifier, and 1.2 parts of isooctyl alcohol. Wherein, the modifier is a mixture of nonylphenol polyoxyethylene ether-3 (OP-3), Mannich base and dipentyl iron in a mass ratio of 12:1:2.

[0058] Its preparation method is with embodiment 1.

Embodiment 3

[0060] A clean and environment-friendly diesel oil comprises 92wt% diesel oil and 8wt% liquid nano-detergent. Wherein, the raw material components of the liquid nano-detergent are in parts by weight: 2 parts of base oil, 0.1 part of isooctyl nitrate, 0.2 part of polyoxymethylene dimethyl ether, 0.05 part of modifier, and 0.5 part of isooctyl alcohol. Among them, the modifier is a mixture of nonylphenol polyoxyethylene ether-3 (OP-3), Mannich base and dipentyl iron in a mass ratio of 9:1:5.

[0061] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com