Preparation method of high-performance asphalt mixture

An asphalt mixture and high-performance technology, applied in the field of high-performance asphalt mixture preparation, can solve the problem that fine aggregates and powders are difficult to distribute evenly, the uniformity of asphalt mixtures is poor, and cementitious materials and fine aggregates cannot be tightly wrapped. cover and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

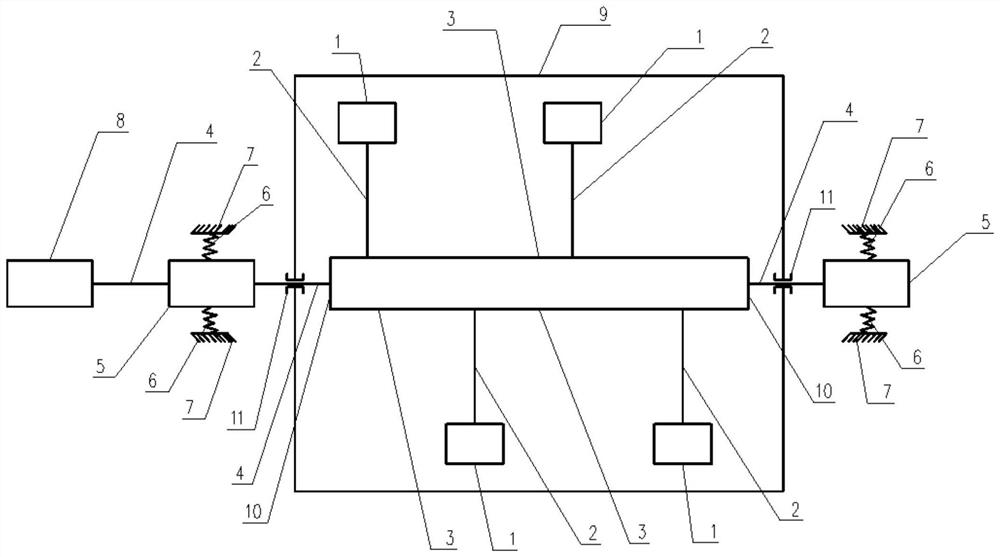

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of high-performance asphalt mixture is based on the above-mentioned mixing equipment, and the specific operations are as follows:

[0021] (1) Set the heating temperature of the mixing chamber to 180°C;

[0022] (2) Put in the sieved coarse and fine aggregates, and stir for 25 seconds, the stirring speed during the stirring process is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0023] (3) Add asphalt and stir for 25 seconds. During the stirring process, the stirring speed is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0024] (4) Add mineral powder and stir for 25 seconds. During the stirring process, the stirring speed is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0025] (5) Unloading and heat preservation for standby.

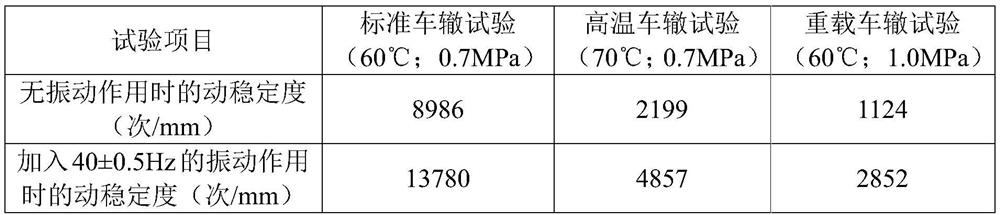

[0026] The performance test of the asphalt mixture prepared by the above method is carried out according to the current domestic standard "Test Regulations for Asphalt and Asphalt Mixtures in...

Embodiment 2

[0054] The preparation method of high-performance asphalt mixture is based on the above-mentioned mixing equipment, and the specific operations are as follows:

[0055] (1) Set the heating temperature of the mixing chamber to 180°C;

[0056] (2) Put in the sieved coarse and fine aggregates, and stir for 28 seconds, the stirring speed during the stirring process is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0057] (3) Add asphalt and stir for 28 seconds, the stirring speed during the stirring process is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0058] (4) Add mineral powder and stir for 28 seconds. During the stirring process, the stirring speed is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0059] (5) Unloading and heat preservation for standby.

[0060] The performance test of the asphalt mixture prepared by the above method is carried out according to the current domestic standard "Test Regulations for Asphalt and Asphalt Mixtures in ...

Embodiment 3

[0084] The preparation method of high-performance asphalt mixture is based on the above-mentioned mixing equipment, and the specific operations are as follows:

[0085] (1) Set the heating temperature of the mixing chamber to 180°C;

[0086] (2) Put in the sieved coarse and fine aggregates, and stir for 30 seconds. During the stirring process, the stirring speed is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0087] (3) Add asphalt and stir for 30 seconds. During the stirring process, the stirring speed is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0088] (4) Add mineral powder and stir for 30 seconds. During the stirring process, the stirring speed is 35±0.5r / min, and the vibration frequency is 40±0.5Hz;

[0089] (5) Unloading and heat preservation for standby.

[0090] The performance test of the asphalt mixture prepared by the above method is carried out according to the current domestic standard "Test Regulations for Asphalt and Asphalt Mixtures i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com