Biodegradable high-performance modified particle material and preparation method thereof

A technology of modified particles and biodegradation, applied in the field of biodegradable materials, can solve the problems of lack of hydrophobicity and antibacterial properties, inability to achieve natural degradation of waste, environmental pollution, etc., and achieve good biodegradability and use stability , good theory and practical significance, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

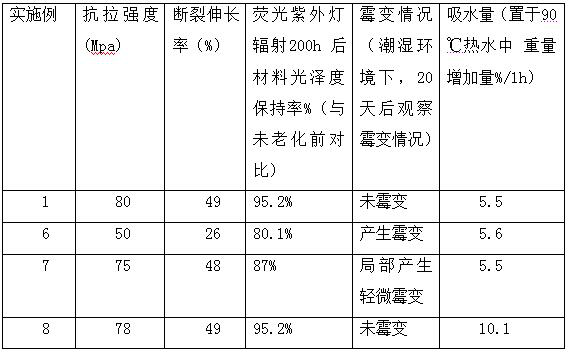

Examples

Embodiment 1

[0118] A biodegradable high performance modified particulate material, prepared from the following raw materials by weight: 90 parts by oxide modified high amylose corn starch, 1-ethyl-3-methylimidazolium acetate 6.5 parts, poloxamines Farm 3.5 parts, corn distillers dried powder, 4 parts of concentrate, 4 parts of coconut husk powder, 3 parts of the modifier composition, PLA 20 parts of polylactic acid, poly (3-hydroxybutyrate -co-3- hydroxyhexanoate) PHBHHx7 parts, BASF ADR epoxy-functional chain extenders, 1 part of maleic anhydride, 0.7 parts of polyoxyethylene (the PEO) 0.7 parts, 4 parts of modified nano carbon fibers, nano calcium carbonate 10 parts; the preparation method comprising the steps of:

[0119] ① weighed according to the composition ratio by weight: high amylose corn starch, 90 parts of 1-ethyl-3-methylimidazolium acetate 6.5 parts, 3.5 parts poloxamer added together in a high speed mixer, sealed lid, stirring 5- after 12 minutes at room temperature, ultrasonic ...

Embodiment 2

[0127] A biodegradable high performance modified particulate material, parts by weight of the following raw materials: 90 parts of oxidatively modified high amylose wheat starch, 1-ethyl-3-methylimidazolium acetate 5 parts of an epoxy large 5 parts of soybean oil, 5 parts of betel nut shell powder, wheat powder, dried and concentrated vinasse 3 parts, 3 parts of the modifier composition, a polylactic acid PLA 20 parts of the epoxy-functional BASF ADR 0.9 parts of chain extender, 0.7 parts of maleic anhydride, polyoxyethylene (PEO) 0.8 parts, 7 parts of a modified carbon nanofiber, octadecyl quaternary ammonium modified nanoclays 15 parts; the preparation method comprising the steps of:

[0128] ① weighed according to the composition ratio by weight: high amylose wheat starch, 90 parts of 1-ethyl-3-methylimidazolium acetate 5 parts, 5 parts of epoxidized soybean oil added to the common high-speed mixer, sealed lid, stirring 5- after 12 minutes at room temperature, ultrasonic vibrat...

Embodiment 3

[0137] A modified particulate material of high performance biodegradable, made from the following raw materials by weight: 90 parts by oxidatively modified high amylose potato starch, 6 parts of lecithin, poloxamer, 4 parts of powder sugar cane vinasse concentrated to dryness 4 parts, 4 parts olive powder, 3 parts of the modifier composition, a polylactic acid PLA 20 parts by BASF ADR epoxy-functional chain extenders, 1 part of maleic anhydride, 0.6 parts of polyoxyethylene (PEO) 0.9 parts, change 8 parts of carbon nano fibers, nano-calcium carbonate 8 parts, 5 parts MWCNTs; preparation method comprising the steps of:

[0138] ① weighed according to the composition ratio by weight: high amylose potato starch 90 parts, 6 parts of lecithin, poloxamer added 4 parts of a common high-speed mixer, sealed lid, 5-12 minutes of stirring at room temperature, ultrasonic vibration 30min, ultrasonic power is 480W, and the resulting material placed in sealed 24h, standby;

[0139] ② weighed acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com