Metal mold surface treatment process

A metal mold and surface treatment technology, which is applied in the direction of metal material coating process, superimposed layer plating, solid-state diffusion coating, etc., can solve the problem of metal mold toughness, insufficient wear resistance, poor corrosion resistance, and reduce the use of molds Life and other issues, to improve performance such as corrosion resistance and cold and heat fatigue resistance, improve wear resistance and corrosion resistance, and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

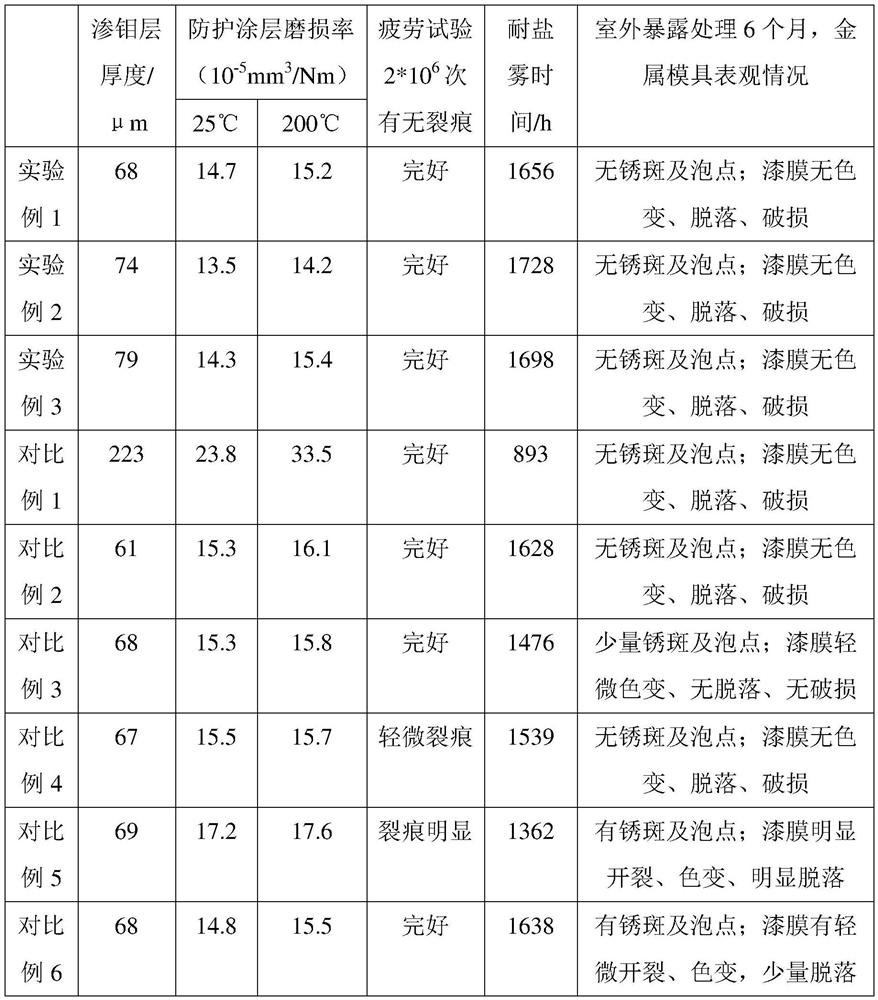

Examples

Embodiment 1

[0045] A metal mold surface treatment process, comprising the following steps:

[0046] Step 1, the preparation of molybdenum sulfide coating;

[0047] S1. Roughen the metal mold made of 4Cr5MoSiV1 so that the surface roughness Ra is 0.8 μm, then clean the metal mold with cleaning solution and absolute ethanol respectively. After cleaning, take out the metal mold and use hot air to clean the metal mold. its blow dry;

[0048] S2. The dried metal mold is placed in the ion chemical heat treatment furnace, the pure molybdenum plate and the metal mold are placed on the two cathodes in turn, the pure molybdenum plate is used as the source electrode for providing molybdenum atoms, and the metal mold is placed on the other cathode. ; Then clean the furnace cavity and pump the pressure in the furnace to 1.0-3.0Pa, then fill in an appropriate amount of inert gas, and then adjust the voltage on the source electrode and the metal mold to an appropriate value; after the adjustment is com...

Embodiment 2

[0075] Compared with Embodiment 1, the difference between this embodiment is as follows:

[0076] In the glow discharge process of step S2, the source voltage is 500V, the working voltage is -500V, the electrode spacing is 30mm, the argon gas pressure is 40Pa, the temperature is 1000°C, and the constant temperature time is 6h.

[0077] In step S3, the mixed gas is formed by mixing carbon disulfide vapor and argon according to a volume ratio of 2:1, and the flow rate of the mixed gas is 0.1 L / min.

[0078] In step S3, the time of infiltration treatment is set to 100min, and the current is set to 1.6A.

[0079] During the deposition of the chromium nitride coating, the argon pressure was 0.4Pa, the deposition bias was 25V, the deposition pressure was 2.3Pa, the deposition temperature was 460°C, and the deposition time was 80min.

[0080] During the deposition of titanium nitride coating, the argon pressure was 0.3Pa, the deposition bias was 100V, the deposition pressure was 5Pa...

Embodiment 3

[0085]Compared with Embodiment 1, the difference between this embodiment is as follows:

[0086] In the glow discharge process of step S2, the source voltage is 1200V, the working voltage is -900V, the electrode spacing is 60mm, the argon gas pressure is 60Pa, the temperature is 1200°C, and the constant temperature time is 8h.

[0087] In step S3, the mixed gas is formed by mixing carbon disulfide vapor and argon according to a volume ratio of 2.5:1, and the flow rate of the mixed gas is 0.12 L / min.

[0088] In step S3, the time of infiltration treatment is set to 130min, and the current is set to 1.8A.

[0089] During the deposition of the chromium nitride coating, the argon pressure was 0.5Pa, the deposition bias was 30V, the deposition pressure was 2.5Pa, the deposition temperature was 480°C, and the deposition time was 110min.

[0090] During the deposition of the titanium nitride coating, the argon pressure was 0.4Pa, the deposition bias was 300V, the deposition pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com