Nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint and preparation method thereof

A nano-reinforced, low surface energy technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as low strength, poor adhesion, complicated construction and difficulty, and achieve weakened binding force , reduce adhesion, easy to fall off by itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Add 80 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 10000mPa·s and 8 parts of fumed silicon dioxide into the dispersion tank of the dispersing machine in proportion, disperse at 4000rpm for 30min at high speed, and then add 2 parts The multi-walled carbon nanotubes continued to disperse at high speed for 15 minutes to obtain nanometer pre-dispersed slurry;

[0065] Component A Add each composition to the dispersing tank of the dispersing machine sequentially in proportion, stir and disperse at a high speed of 4000 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0066] Components B and C are mixed according to the ratio and canned for use.

[0067] Before use, mix and stir evenly according to the ratio of A:B:C=20:4:1, and obtain a silicone low surface energy antifouling coating after coating and curing.

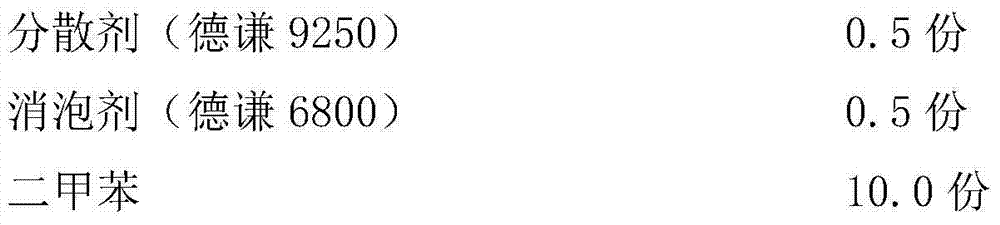

[0068] The composition of group A:

[0069]

[0070]

[0...

Embodiment 2

[0079] Add 75 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa·s and 8 parts of fumed silicon dioxide into the dispersion tank of the dispersing machine in proportion, disperse at 4000rpm for 30min at high speed, and then add 2 parts The single-walled carbon nanotubes continued to disperse at a high speed for 15 minutes to obtain a nano-predispersed slurry;

[0080] Component A Add each composition to the dispersing tank of the dispersing machine sequentially in proportion, stir and disperse at a high speed of 5000 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0081] Components B and C are mixed according to the ratio and canned for use.

[0082] Before use, mix and stir evenly according to the ratio of A:B:C=18:4:1, and obtain a silicone low surface energy antifouling coating after coating and curing.

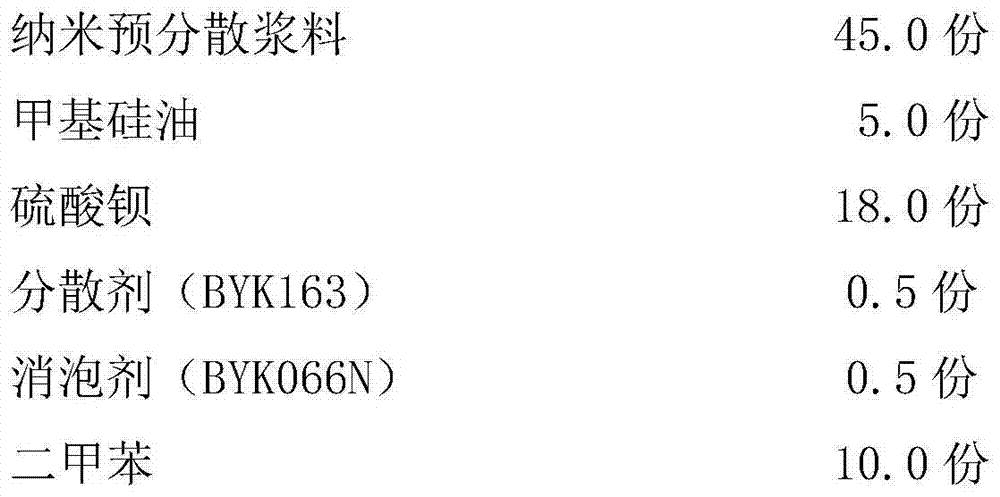

[0083] The composition of group A:

[0084]

[0085] Component...

Embodiment 3

[0093] Proportionally, 50 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa·s and 40 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2800mPa·s (purchased from Shandong University Yi Chemical Co., Ltd.) and 6 parts of fumed silica were added to the dispersing tank of the disperser, dispersed at a high speed for 30 minutes at 3500 rpm, then added 4 parts of nano-zinc oxide and continued to disperse at a high speed for 15 minutes to obtain a nano-predispersed slurry;

[0094] For component A, add each composition into the dispersing tank of the dispersing machine in sequence in proportion, stir and disperse at a high speed of 3500 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0095] Components B and C are mixed according to the ratio and canned for use.

[0096] Before use, mix and stir evenly according to the ratio of A:B:C=16:3:0.5, and obtain a silicone lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com