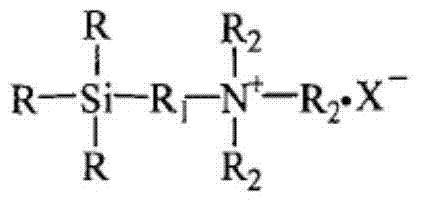

Nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint and preparation method thereof

A low surface energy, antifouling paint technology, applied in the fields of luminescent paint, antifouling paint, anti-fouling paint, underwater paint, can solve the problem of insufficient antifouling performance, achieve easy self-shedding, improve luminous performance, paint The effect of low surface energy of the layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Add 70 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 10000mPa·s, 1 part of dispersant BYK161, 10 parts of xylene and 3 parts of domestic anatase nano-titanium dioxide into the dispersion tank of the dispersing machine in proportion In the process, disperse at a high speed for 30 minutes at 4000rpm, then add 16 parts of blue phosphor SB-8C and continue to disperse at a high speed for 15 minutes to obtain a nano-fluorescent pre-dispersion.

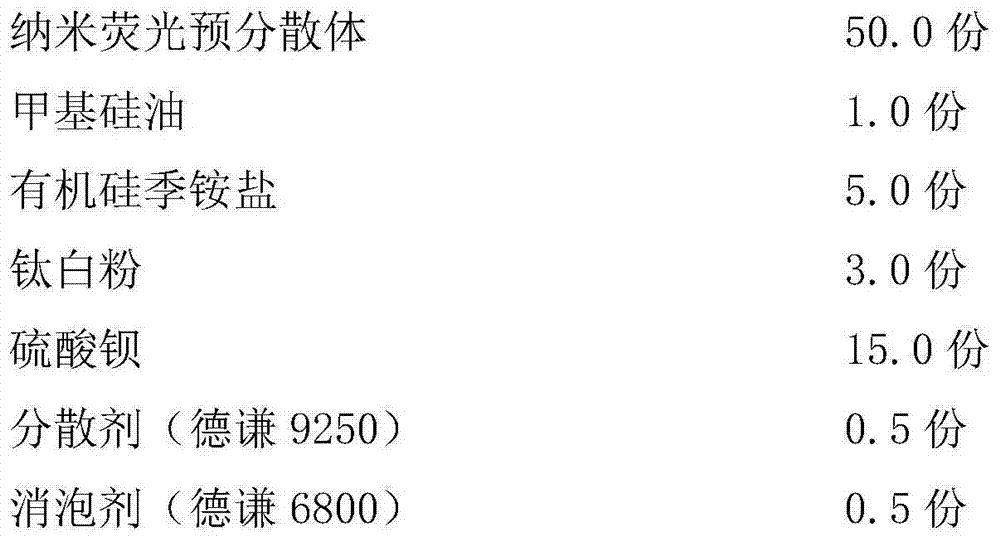

[0074] For component A, add each composition into the dispersing tank of the dispersing machine in sequence in proportion, stir and disperse at a high speed of 2000 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0075] Components B and C are mixed according to the ratio and canned for use.

[0076] Before use, mix and stir evenly according to the ratio of A:B:C=30:4:1, and obtain a silicone low surface energy antifouling coating after...

Embodiment 2

[0088] Add 60 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa·s, 1 part of dispersant BYK161, 8 parts of xylene and 2 parts of domestic anatase nano-titanium dioxide into the dispersion tank of the dispersing machine in proportion In the process, disperse at a high speed for 30 minutes at 4000 rpm, then add 10 parts of yellow-green phosphor SP-4 and continue high-speed dispersion for 15 minutes to obtain a nano-fluorescent pre-dispersion.

[0089] Component A Add each composition to the dispersing tank of the dispersing machine in sequence in proportion, stir and disperse at a high speed of 1500 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0090] Components B and C are mixed according to the ratio and canned for use.

[0091] Before use, mix and stir evenly according to the ratio of A:B:C=25:4:1, and obtain a silicone low surface energy antifouling coating after coatin...

Embodiment 3

[0102] Proportionally mix 50 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa·s, 20 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2800mPa·s, and 1 part of dispersant Add BYK161, 10 parts of xylene and 3 parts of domestic anatase nano-titanium dioxide into the dispersion tank of the dispersing machine, disperse at a high speed of 4500rpm for 30 minutes, then add 16 parts of yellow-green phosphor SP-4 and continue high-speed dispersion for 15 minutes to obtain nano-fluorescence pre-dispersion.

[0103] For component A, add each composition into the dispersing tank of the dispersing machine sequentially in proportion, stir and disperse at a high speed of 1800 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0104] Components B and C are mixed according to the ratio and canned for use.

[0105] Before use, mix and stir evenly according to the ratio of A:B:C=35:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com