Anode slurry of lithium secondary battery, anode and battery including the same

A cathode slurry, secondary battery technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of limited performance improvement, low capacity and discharge ratio, and high battery internal resistance, to improve performance, High capacity and discharge ratio, lower surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Various methods known in the art can be used for the preparation method of the positive electrode and the negative electrode.

[0035] The composition of the electrolyte solution is well known to those skilled in the art. Generally speaking, the electrolyte solution contains a non-aqueous solvent and an electrolyte dissolved in the non-aqueous solvent. The content of the electrolyte is generally 0.5-2.0 mol / l.

[0036] The kind of described non-aqueous solvent is well known to those skilled in the art, can use various known non-aqueous solvents, preferably use the mixed solvent of chain ester and cyclic acid ester; Described chain ester can be Dimethyl carbonate, diethyl carbonate, ethyl propyl carbonate, diphenyl carbonate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, dimethoxyethane, diethoxy ethane and its chain organic esters containing fluorine, sulfur and unsaturated bonds or a mixture thereof; the cyclic esters can be selected from ethylene c...

Embodiment 1

[0041] 1. Preparation of positive electrode slurry for lithium-ion secondary batteries

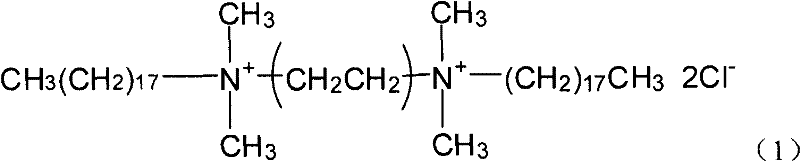

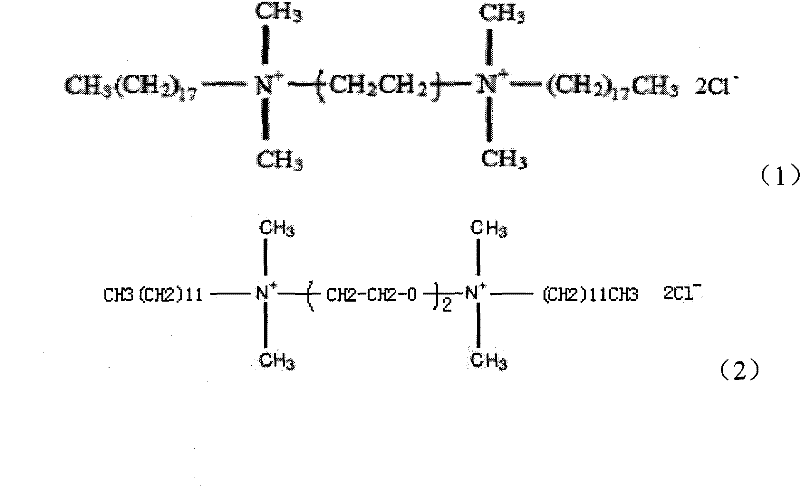

[0042] Add 4000g of solvent N-methylpyrrolidone (NMP) and 10g of ethylene bis(octadecyldimethylammonium chloride) (Henan Province Daochun Chemical Technology Co., Ltd.) to the container with stirrer.

[0043] Stir in the container for 5 minutes, then add 400g conductive agent acetylene black and 300g binder polyvinylidene fluoride (PVDF) powder, stir for 5 minutes to obtain conductive agent slurry, then add 10kg lithium cobaltate and stir for 20 minutes to prepare It can be used as positive electrode slurry for lithium ion secondary battery.

[0044] 2. Preparation of positive electrode

[0045] The positive electrode slurry of the lithium-ion secondary battery obtained above is uniformly coated on the aluminum foil by drawing the slurry, dried, pressed into sheets, and cut into positive electrode sheets of 490 × 43 mm, and each positive electrode sheet contains 7.8 grams of cobalt respec...

Embodiment 2

[0054] Lithium-ion secondary battery A2 was prepared in the manner described in Example 1, except that when preparing the positive electrode slurry of the lithium-ion secondary battery, the amount of gemini surfactant added was 30 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com