Preparation method of carbon nanotube/ceramic matrix composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of carbon nanotubes/ceramic matrix composites, which can solve problems such as uneven dispersion, affecting the performance of composite materials, and the inability to disperse carbon nanotubes and ceramic powders. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

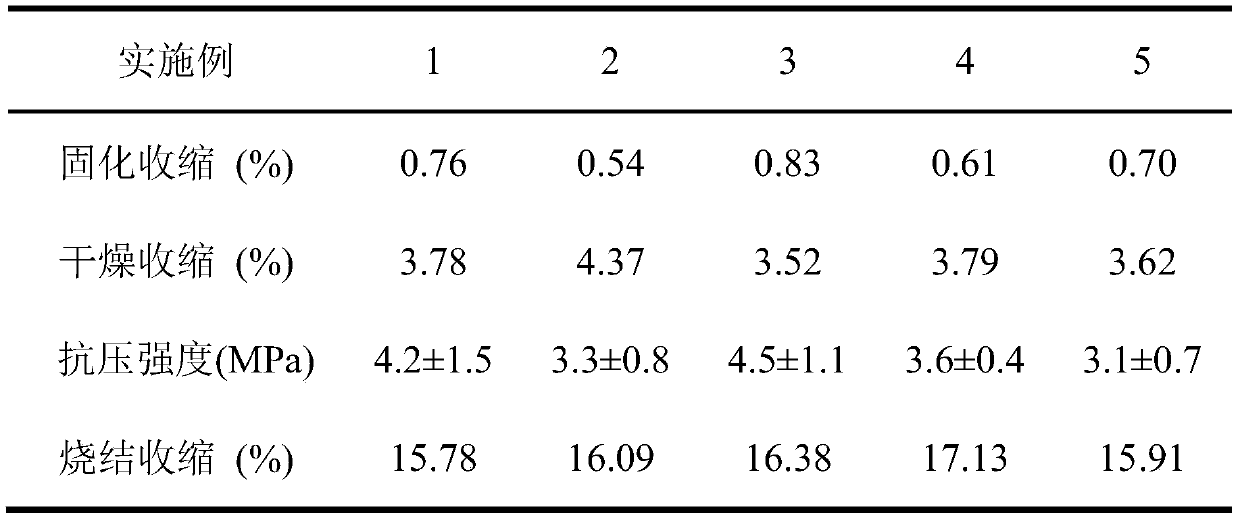

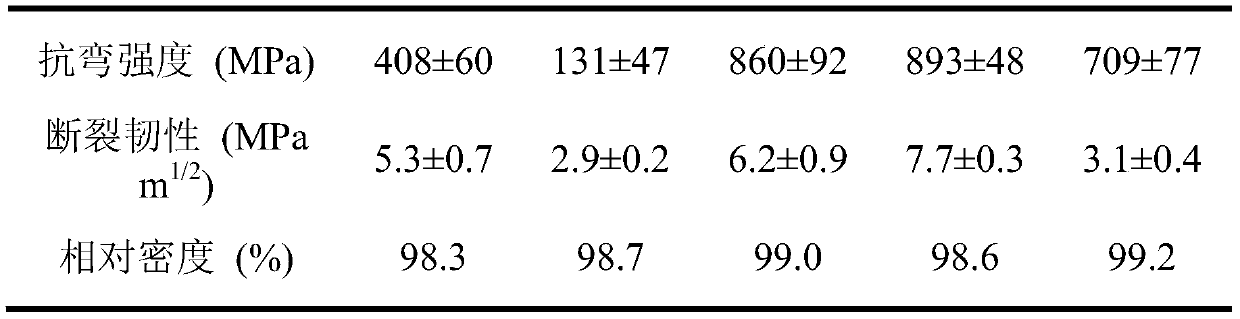

Embodiment 1

[0033] Carbon nanotube / alumina composite ceramics were prepared with isobam 104 as dispersant.

[0034] Mix 1 g of carbon nanotubes, 0.05 g of isobam 104 and 20 g of water, add ammonia water to adjust the pH to 9.5, and stir ultrasonically for 12 hours to obtain a carbon nanotube suspension for use. Mix 198.1 grams of alumina powder, 0.6 grams of isobam 104, 30 grams of water and the above suspension of carbon nanotubes, adjust the pH value to 9.5 with ammonia water, and ball mill for 24 hours to obtain a solid phase content of 50% by volume. %, the mass of carbon nanotubes accounts for 0.5% of the mass of ceramic powder. The obtained mixed suspension was vacuum-degassed for 45 minutes, injected into a non-porous metal mold, treated in a water bath at 70° C. for 1 hour, and demoulded to obtain a wet body of a composite ceramic material. The obtained wet body of the composite ceramic material was placed at room temperature for 12 hours, then put into an oven, and dried at 80° ...

Embodiment 2

[0037] Carbon nanotube / silica composite ceramics were prepared with isobam 104 as dispersant.

[0038] Mix 1.62 grams of carbon nanotubes, 0.08 grams of isobam 104 and 24 grams of water, add ammonia water to adjust the pH value to 10.5, and ultrasonically stir for 12 hours to obtain a suspension of carbon nanotubes for use. Mix 135.7 grams of silicon oxide powder, 0.81 grams of isobam104, 24 grams of water and the above suspension of carbon nanotubes, adjust the pH value to 10.5 with ammonia water, and ball mill for 24 hours to obtain a solid phase content of 52% in volume percentage , the mixed suspension in which the mass of carbon nanotube accounts for 1.2% of the mass of ceramic powder. The obtained mixed suspension was vacuum degassed for 15 minutes, injected into a non-porous metal mold, treated in a water bath at 70° C. for 1 hour, and a wet body of a composite ceramic material was obtained after demoulding. The obtained wet body of the composite ceramic material was p...

Embodiment 3

[0041] Carbon nanotube / zirconia composite ceramics were prepared with isobam 600 as dispersant.

[0042] Mix 0.9 g of carbon nanotubes, 0.045 g of isobam 600 and 15 g of water, add ammonia water to adjust the pH value to 10, and ultrasonically stir for 12 hours to obtain a suspension of carbon nanotubes for use. Mix 297.45 grams of zirconia powder, 1.18 grams of isobam600, 35 grams of water and the above suspension of carbon nanotubes, adjust the pH value to 10 with ammonia water, and ball mill for 24 hours to obtain a solid phase content of 50% in volume percentage , the mixed suspension in which the mass of carbon nanotube accounts for 0.3% of the mass of ceramic powder. The obtained mixed suspension was vacuum degassed for 30 minutes, injected into a non-porous metal mold, treated in a water bath at 70° C. for 1 hour, and demoulded to obtain a wet body of a composite ceramic material. The obtained wet body of the composite ceramic material was placed at room temperature fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com