Composite nano cuprous oxide/zinc oxide material with photocatalytic performance as well as preparation method and application thereof

A composite, photocatalytic technology, applied in catalyst activation/preparation, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of poor stability and high cost of single cuprous oxide photocatalyst, achieve Eliminate the influence of impurities, facilitate large-scale production, and the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

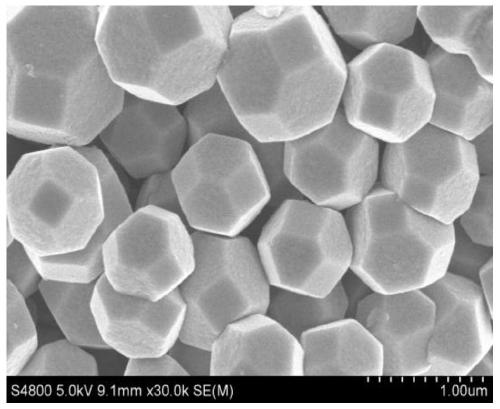

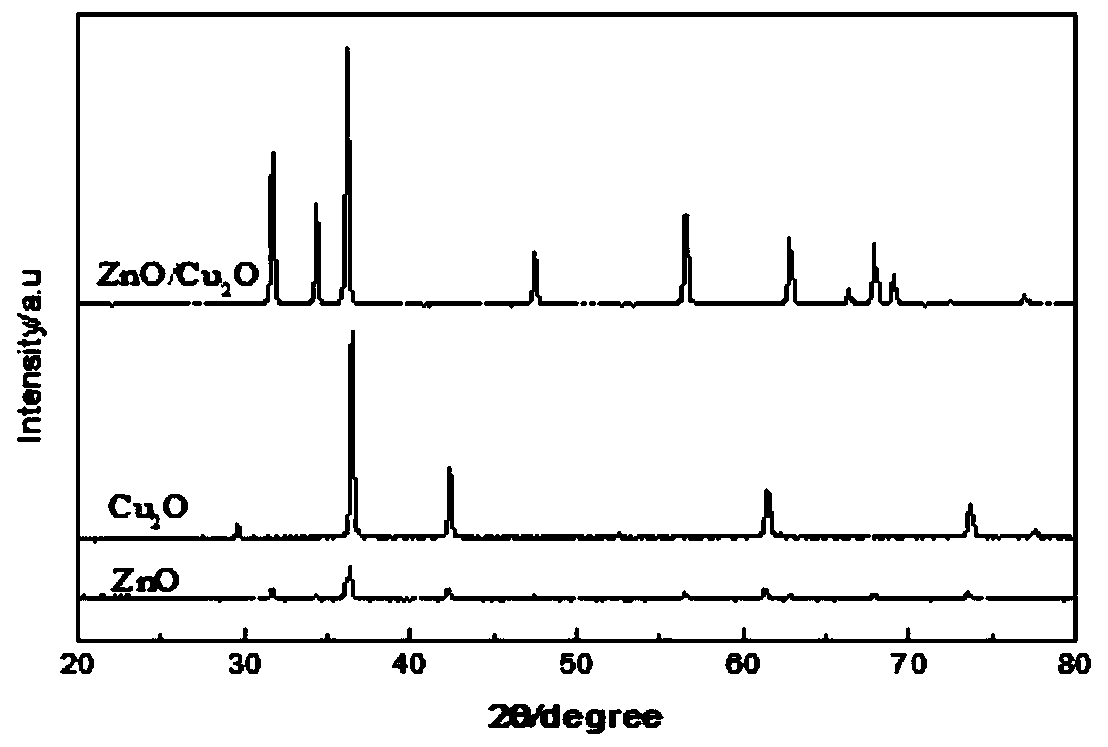

[0038] Step 1: Add 0.172 g of CuCl 2 2H 2 O, the PVP (dodecylpyrrolidone) of 3.3g and the Na of 0.1g 3 C 6 h 5 0 7 2H 2 O, 100mL H 2 O was added to a 250mL three-necked flask, and the three-necked flask was placed in a constant temperature water tank at 55°C, and stirred evenly to completely dissolve the solid; while stirring, 10mL of NaOH solution with a concentration of 0.6mol / L was added dropwise, and after the addition was completed, the Continue to react at ℃ for 30 min; add 10 mL of C with a concentration of 2 mol / L dropwise. 6 h 8 0 6 Solution, after the dropwise addition, continue to react at 55°C for 30min; turn off the stirring, let it stand at 55°C for 3h, wash the obtained precipitate with distilled water and absolute ethanol alternately for 3 times, and then dry to obtain tetradecahedral structure Cu 2 O powder;

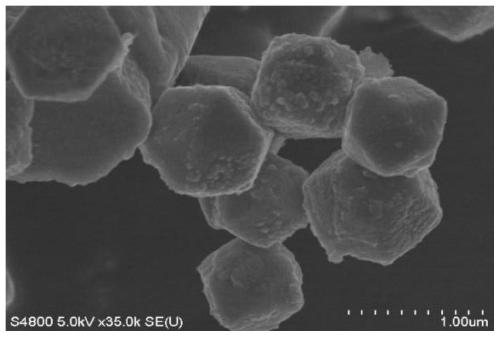

[0039] Step 2: Add 0.2g Cu 2 Add O powder and 0.5g PVP into 25mL distilled water, ultrasonically disperse for 30 minutes, then add 0.15g zin...

Embodiment 2

[0042] Step 1: Add 0.172 g of CuCl 2 2H 2 O, the PVP (dodecylpyrrolidone) of 3.3g and the Na of 0.1g 3 C 6 h 5 0 7 2H 2 O, 100mL H 2 O was added to a 250mL three-necked flask, and the three-necked flask was placed in a constant temperature water tank at 45°C, and stirred evenly to completely dissolve the solid; while keeping stirring, 10mL of NaOH solution with a concentration of 0.6mol / L was added dropwise. Continue to react at ℃ for 30 min; add 10 mL of C with a concentration of 2 mol / L dropwise. 6 h 8 0 6 Solution, after the dropwise addition, continue to react at 45°C for 30min; turn off the stirring, let stand at 45°C for 3h, wash the obtained precipitate with distilled water and absolute ethanol alternately for 3 times, and then dry to obtain tetradecahedral structure Cu 2 O powder;

[0043] Step 2: Add 0.2g Cu 2 Add O powder and 0.5g PVP into 25mL distilled water, ultrasonically disperse for 30 minutes, then add 0.15g zinc acetate, and stir thoroughly to obt...

Embodiment 3

[0046] Step 1: Add 0.172 g of CuCl 2 2H 2 O, the PVP (dodecylpyrrolidone) of 3.3g and the Na of 0.1g 3 C 6 h 5 0 7 2H 2 O, 100mL H 2 O was added to a 250mL three-necked flask, and the three-necked flask was placed in a constant temperature water tank at 65°C, and stirred evenly to completely dissolve the solid; while keeping stirring, 10mL of NaOH solution with a concentration of 0.6mol / L was added dropwise, and after the addition was completed, the Continue to react at ℃ for 30 min; add 10 mL of C with a concentration of 2 mol / L dropwise. 6 h 8 0 6 Solution, after the dropwise addition, continue to react at 65°C for 30min; turn off the stirring, let stand at 65°C for 3h, wash the obtained precipitate with distilled water and absolute ethanol alternately for 3 times, and then dry to obtain tetradecahedral structure Cu 2 O powder;

[0047] Step 2: Add 0.2g Cu 2 Add O powder and 0.5g PVP into 25mL distilled water, ultrasonically disperse for 30 minutes, then add 0.15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com