Fiber dispersion mill of organic fiber enhanced composite material and fiber dispersion method

A reinforced composite material and organic fiber technology, which is applied in the field of concrete, can solve the problems that the fiber and powder cannot be mixed and ground together, and achieve the effect of simple structure, guaranteed workability, and easy pouring and pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

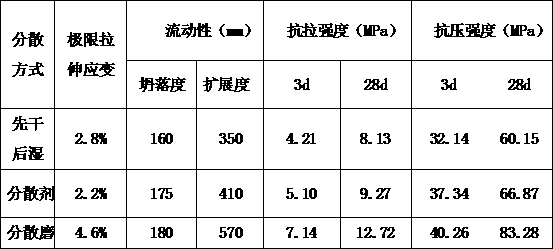

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples.

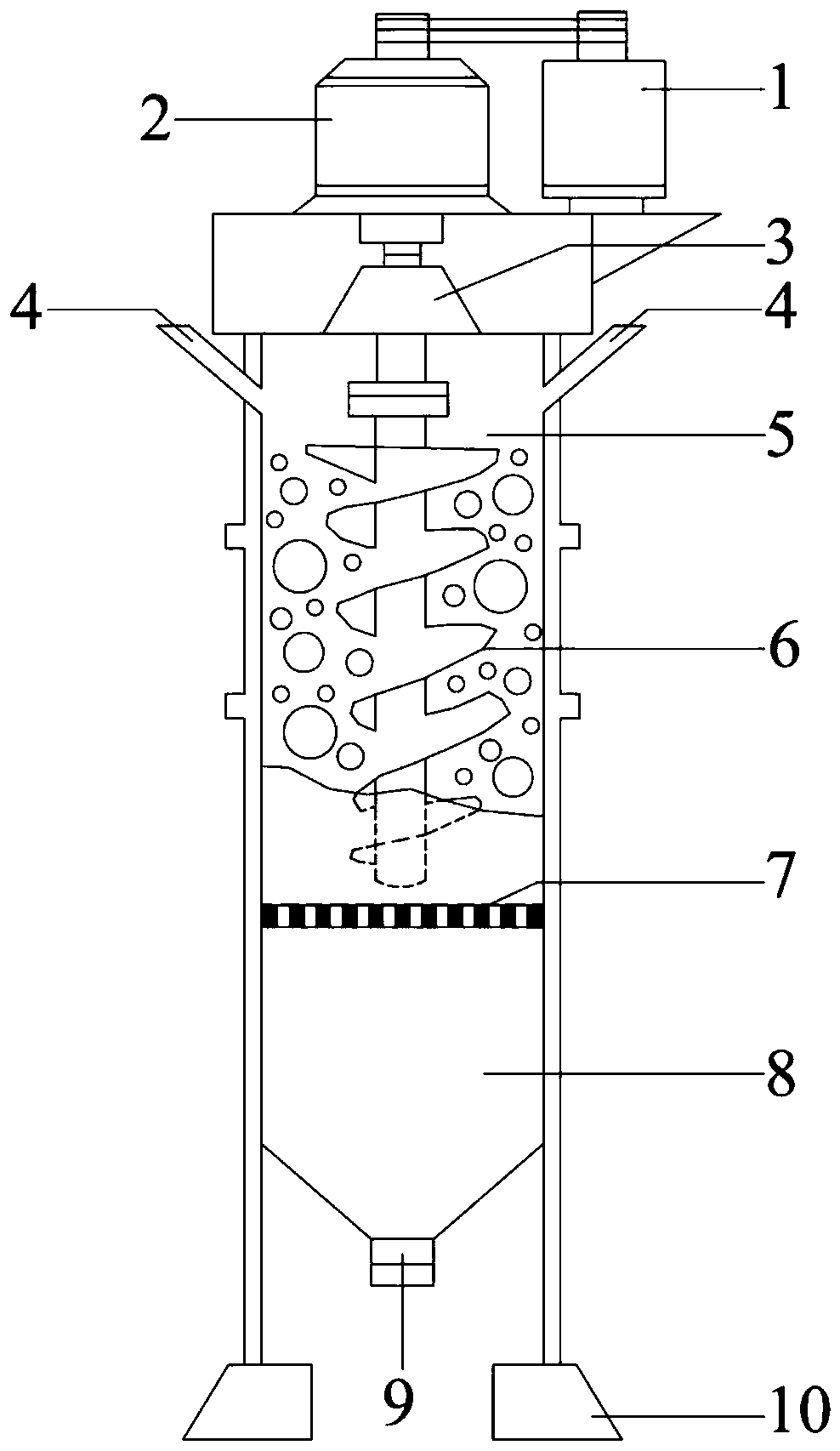

[0030] like figure 1 As shown, a fiber dispersing mill of organic fiber reinforced composite material proposed by the present invention includes a cylinder body, a stirrer 6 , a reducer 2 and a motor 1 . The motor shaft is provided with a driving pulley, the power input shaft of the reducer 2 is provided with a driven pulley, and power is transmitted between the two through a V-belt.

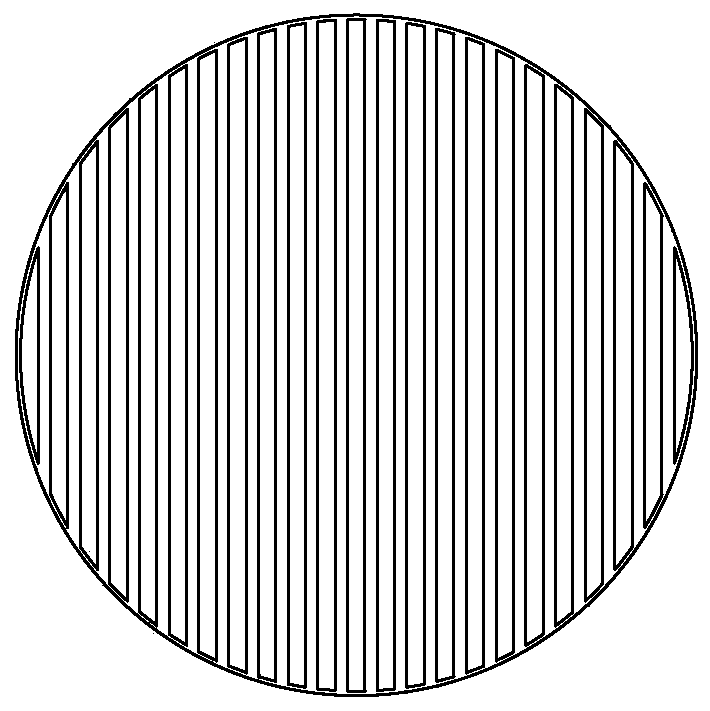

[0031] The cylinder is divided up and down by the grate plate 7 into a mixed grinding bin 5 and an aggregate bin 8 . A cement feeding port 41 and a fiber feeding port 42 are arranged on the upper part of the side of the mixing chamber, and a number of steel balls 51 are arranged inside the mixing chamber 5 . The top of the mixing chamber is provided with a bearing seat 3, and the reducer 2 is arranged just above the bearing seat. The agitator 6 includes a main shaft and a helical blade wound on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com