All-degradable thermoplastic starch/polylactic acid blend material and preparation method thereof

A technology of thermoplastic starch and polylactic acid, which is applied in the field of thermoplastic starch/polylactic acid blend materials and their preparation, can solve the problems of poor mechanical properties and heat resistance of materials, insignificant improvement, high production cost, etc., and achieve good mechanical properties, The effect of high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

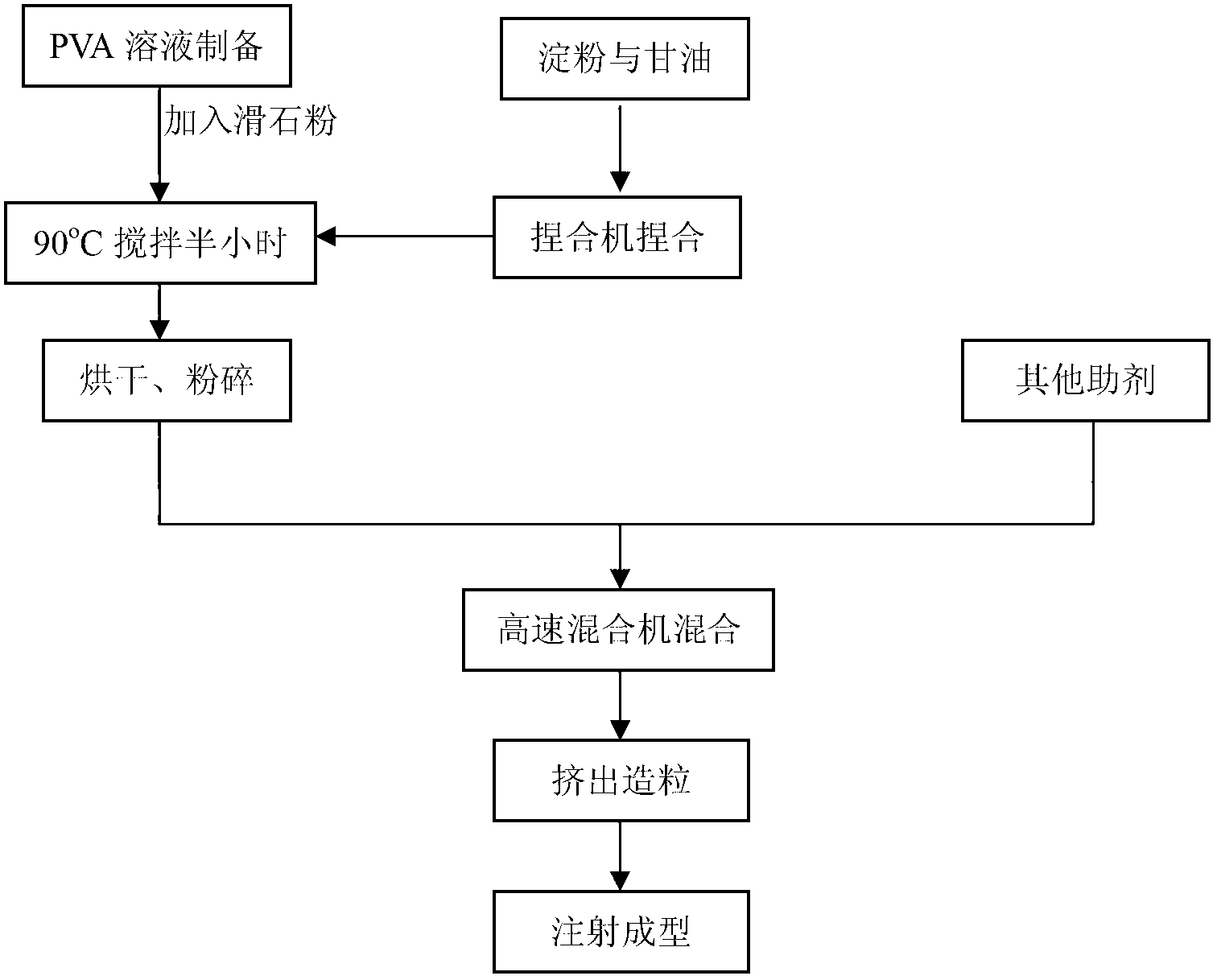

Embodiment 1

[0043] Dry tapioca starch and polylactic acid; accurately weigh 40% of tapioca starch and 15% of glycerin, put them in a kneader, knead them at 110°C for 15 minutes, take them out, cool them, and crush them to obtain thermoplastic starch; accurately weigh polyethylene Put 1% alcohol in a round-bottomed flask, inject an appropriate amount of deionized water (to make the mass concentration of polyvinyl alcohol 1%), immerse the flask in a constant temperature water tank at 90°C and stir, and the polyvinyl alcohol will dissolve after 30 minutes. Place the thermoplastic starch and 2% of the weighed talcum powder in the round-bottomed flask, take out the residue in the round-bottomed flask after 30 minutes, and pulverize it with a pulverizer after drying; And accurately weighed polylactic acid 34%, GPOE7%, liquid paraffin 0.3%, lysozyme 0.7%, put it in a high-speed mixer and blend for 5 minutes, add the blend to a twin-screw extruder to extrude and granulate, and the extruder The te...

Embodiment 2

[0045]Dry tapioca starch and polylactic acid; accurately weigh 55% of tapioca starch and 18% of glycerin, place them in a kneader, knead at 120°C for 12 minutes, take them out, cool and crush them to obtain thermoplastic starch; accurately weigh polyethylene Put 2% alcohol in a round-bottomed flask, inject an appropriate amount of deionized water (to make the mass concentration of polyvinyl alcohol 4%), immerse the flask in a constant temperature water bath at 90°C and stir, and the polyvinyl alcohol will dissolve after 30 minutes. Put the thermoplastic starch and 5% of the weighed talcum powder in the round-bottomed flask, take out the residue in the round-bottomed flask after 30 minutes, and pulverize it with a pulverizer after drying; And accurately weighed polylactic acid 14%, GPOE 5%, liquid paraffin 0.2%, lysozyme 0.8% and blended in a high-speed mixer for 5 minutes, the blend was added to a twin-screw extruder for extrusion granulation, and the extruder The temperature ...

Embodiment 3

[0047] Dry tapioca starch and polylactic acid; accurately weigh 70% of tapioca starch and 14% of glycerin, put them in a kneader, knead them at 130°C for 8 minutes, take them out, cool them, and crush them to obtain thermoplastic starch; accurately weigh polyethylene Put 1% alcohol in a round-bottomed flask, inject an appropriate amount of deionized water (to make the mass concentration of polyvinyl alcohol 4%), immerse the flask in a constant temperature water bath at 90°C and stir, and the polyvinyl alcohol will dissolve after 30 minutes. Put the thermoplastic starch and 1% of the weighed talcum powder in the round bottom flask at the same time, take out the residue in the round bottom flask after 30 minutes, and pulverize it with a pulverizer after drying; And accurately weighed polylactic acid 8%, GPOE 5%, liquid paraffin 0.1%, lysozyme 0.9% and blended in a high-speed mixer for 5 minutes, the blend was added to a twin-screw extruder for extrusion granulation, and the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com