Preparation method for maleic anhydride-grafted polypropylene

A technology of grafting polypropylene and maleic anhydride, which is applied in the field of preparation of maleic anhydride grafted polypropylene, can solve problems such as high cost of maleic anhydride grafted polypropylene, difficulty and cost of industrialization, and complicated preparation process , to achieve the effects of short reaction time, low production cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of 0.5mol / L hydrochloric acid standard solution is as follows:

[0040] Weigh 22ml of hydrochloric acid, dilute to 500ml of water, and shake well.

[0041] The calibration method of 0.5mol / L hydrochloric acid standard solution is as follows:

[0042] Weigh 0.95g of the working standard reagent anhydrous sodium carbonate, which is burned in a high-temperature furnace at 270°C-300°C to constant weight, dissolve it in 50ml of water, add 10 drops of bromocresol green-methyl red indicator solution, and use the prepared Titrate the hydrochloric acid solution until the solution turns from green to dark red, boil for 2 minutes, continue to titrate after cooling until the solution turns dark red again, and do a blank experiment at the same time. Then the concentration of the standard solution of hydrochloric acid is C HCL =1000m / (V 1 -V 2 ) M, where M is 52.994, which is half of the molecular weight of sodium carbonate; V 1 is the volume of hydrochlor...

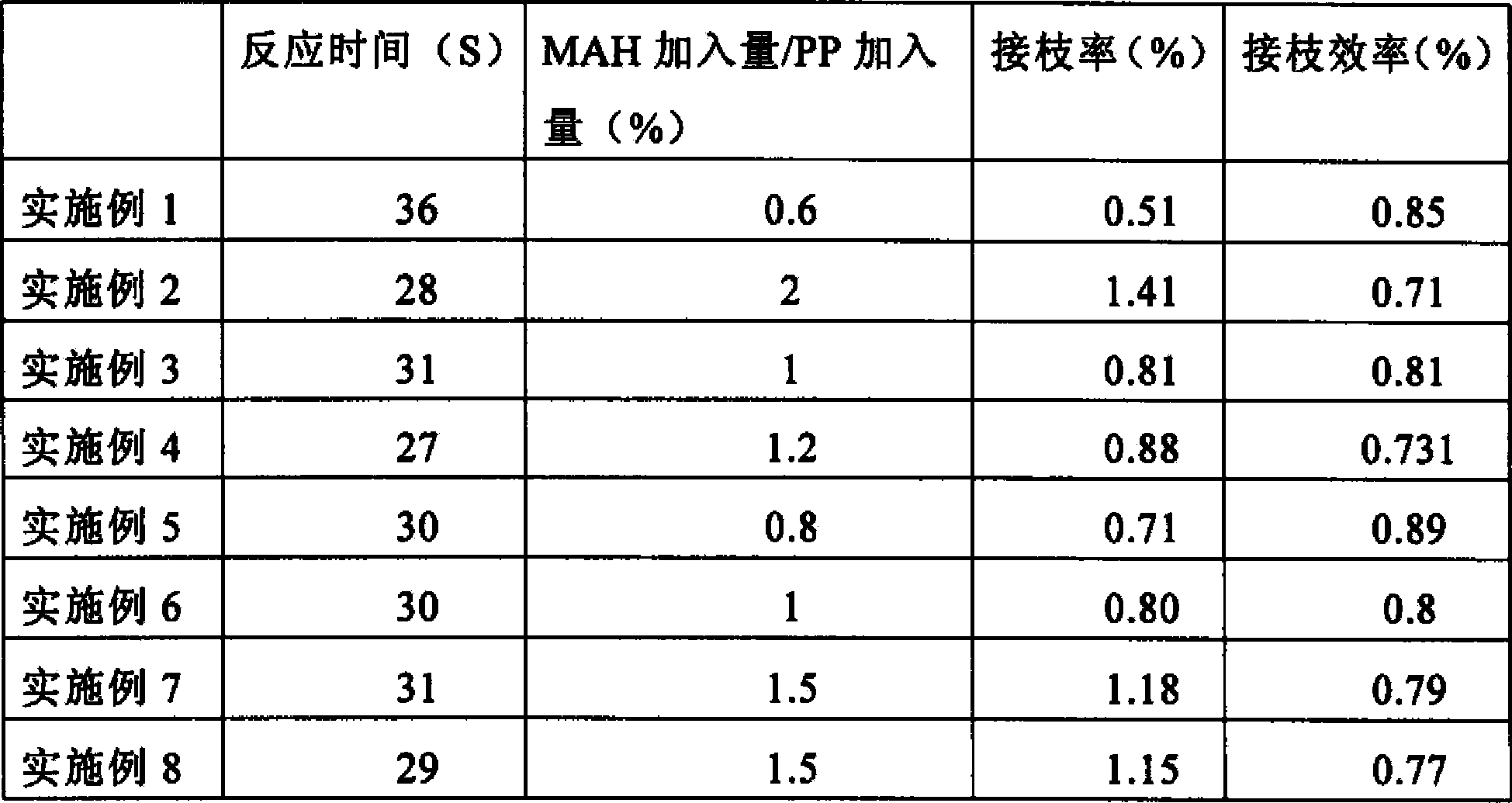

Embodiment 1

[0045] a. count by weight, take by weighing 0.4 part of initiator DTBP, 0.6 part of styrene, and mix uniformly;

[0046] b. Counting in parts by weight, add 100 parts of polypropylene T30S and 0.6 parts of maleic anhydride to a high-speed mixer, mix for 1 min, and simultaneously add the mixture obtained in step a dropwise;

[0047] c. The mixture obtained in step b is added to a twin-screw extruder, blended and extruded, and melt grafted to prepare maleic anhydride grafted polypropylene, and the measured grafting rate is 0.51%. .

[0048]The diameter of the twin-screw extruder is 30mm, the aspect ratio is 35, the speed of the main engine is 200r / min, the speed of feeding is 40r / min, and the temperature is set as: 1 zone 100°C, 2 zone 160°C, 3 zone 180°C, 4 zone 190 ℃, zone 5 190℃, zone 6 190℃, head 190℃.

Embodiment 2

[0050] a. count by weight, take by weighing 2 parts of initiator DTBP, 2 parts of styrene, mix uniformly;

[0051] b. Counting in parts by weight, add 100 parts of polypropylene 1215C and 2 parts of maleic anhydride to a high-speed mixer, mix for 3 minutes, and simultaneously add the mixture obtained in step a dropwise;

[0052] c. The mixture obtained in step b was added to a twin-screw extruder, blended and extruded, and melted and grafted to prepare maleic anhydride grafted polypropylene, and the measured grafting rate was 1.41%.

[0053] The diameter of the twin-screw extruder is 92mm, the length-to-diameter ratio is 52, the main engine speed is 360r / min, the feeding speed is 60r / min, and the temperature settings are: 1 zone 100°C, 2 zone 130°C, 3 zone 160°C, 4 zone 175 ℃, zone 5 190°C, zone 6 200°C, zone 7 200°C, zone 8 200°C, zone 9 200°C, zone 10 200°C, zone 11 200°C, zone 12 200°C, head 210°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com