Preparation method of fluorescent carbon quantum dot probe for detecting beryllium in water

A technology for carbon quantum dots and water detection, which is applied in the field of rapid detection of beryllium ions in water, can solve the problems of difficult preparation and storage of hexamethylenetetramine buffer solution, cumbersome sample preparation and processing process, cumbersome and complicated detection, etc. Good performance, low cost, and less reading interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

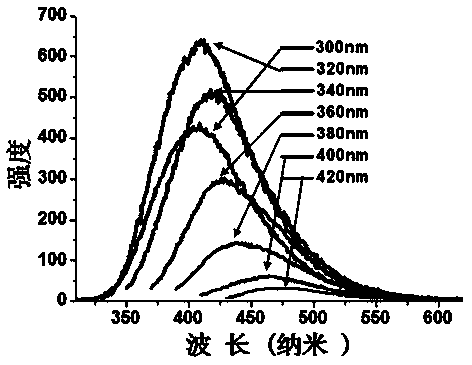

[0026] A method for preparing a fluorescent carbon quantum dot probe for detecting beryllium in water, comprising the steps of:

[0027] (1) Prepare a citric acid solution with a concentration of 0.04g / ml;

[0028] (2) Weigh urea and add it to the above citric acid solution, stir evenly to obtain a mixed solution, the concentration of the urea is 0.01g / ml;

[0029] (3) Transfer the above mixed solution to a hydrothermal reaction kettle, react at 200°C for 5 hours, and wait for the reaction kettle to cool down to room temperature naturally to obtain a brown aqueous solution;

[0030] (4) First use a high-speed centrifuge to centrifuge the brown aqueous solution at 10,000 rpm for 10 minutes to remove larger particles; then use a 1000Da dialysis bag for dialysis for 24 hours to remove unreacted substances and impurity ions, and then fill the brown aqueous solution Put it into a pear-shaped bottle, use a rotary evaporator to concentrate at a speed of 40 rpm and a heating temperat...

Embodiment 2

[0033] A method for preparing a fluorescent carbon quantum dot probe for detecting beryllium in water, comprising the steps of:

[0034] (1) Prepare a citric acid solution with a concentration of 0.04g / ml;

[0035] (2) Weigh urea and add it to the above citric acid solution, stir evenly to obtain a mixed solution, the concentration of the urea is 0.02g / ml;

[0036] (3) Transfer the above mixed solution to a hydrothermal reaction kettle, react at 200°C for 6 hours, and wait for the reaction kettle to cool down to room temperature naturally to obtain a brown aqueous solution;

[0037] (4) First use a high-speed centrifuge at 10,000 rpm for 10 minutes to remove larger particles; then use a 1000Da dialysis bag for 24 hours to remove unreacted substances and impurity ions, and then put the brown aqueous solution into pears shaped bottle, using a rotary evaporator at a rotation speed of 60 rpm and a heating temperature of 70°C to concentrate for 2 hours, and finally dried in a va...

Embodiment 3

[0040] A method for preparing a fluorescent carbon quantum dot probe for detecting beryllium in water, comprising the steps of:

[0041] (1) Prepare a citric acid solution with a concentration of 0.04g / ml;

[0042] (2) Weigh urea and add it to the above citric acid solution, stir evenly to obtain a mixed solution, the concentration of the urea is 0.03g / ml;

[0043] (3) Transfer the above mixed solution to a hydrothermal reaction kettle, react at 200°C for 5 hours, and wait for the reaction kettle to cool down to room temperature naturally to obtain a brown aqueous solution;

[0044] (4) First use a high-speed centrifuge at 10,000 rpm for 10 minutes to remove larger particles; use a 1000Da dialysis bag for 24 hours to remove unreacted substances and impurity ions, and then put the brown aqueous solution into the pear-shaped The bottle was concentrated with a rotary evaporator at a rotation speed of 50 rpm and a heating temperature of 60°C for 3 hours, and finally dried in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com