Avalanche photodiode

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve difficult problems and achieve low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

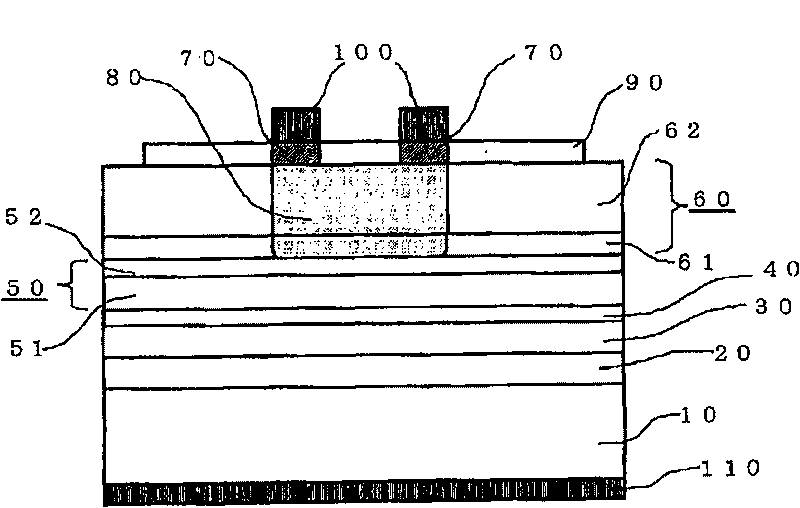

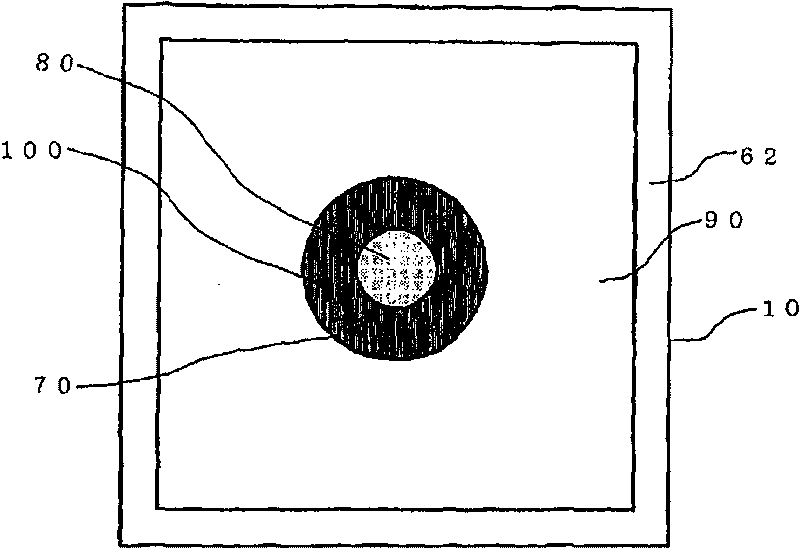

[0026] figure 1 is a schematic cross-sectional view of an avalanche photodiode in Embodiment 1 for implementing the present invention. In this embodiment, the first conductivity type is n-type and the second conductivity type is p-type for description.

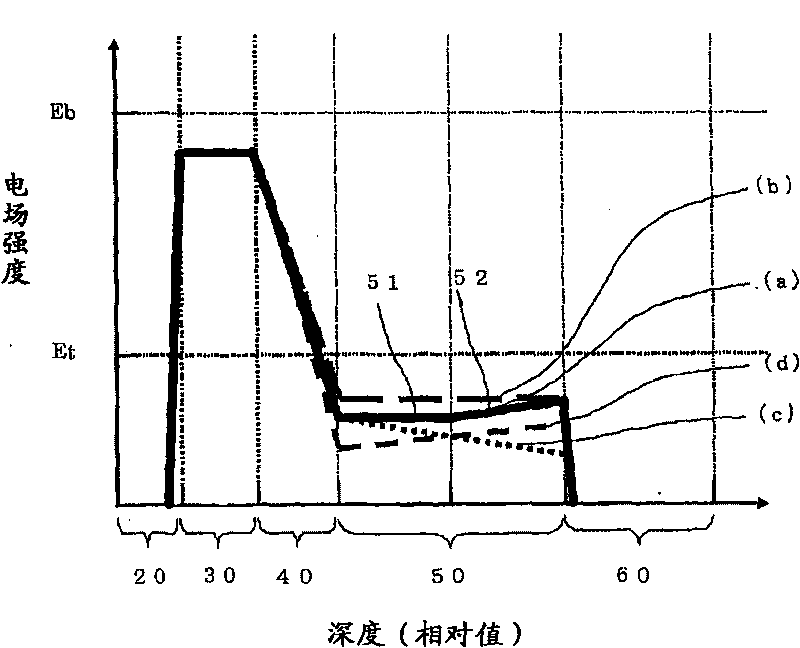

[0027] figure 1 Among them, a low-resistance n-type InP material substrate 10 is formed on the first main surface with a film thickness of 0.1-1 μm and a carrier concentration of 1-5×10 18 cm -3 , The buffer layer 20 of n-type InP material. Formed on the buffer layer 20 with a film thickness of 0.1 to 0.5 μm and a carrier concentration of 0.1 to 3×10 15 cm -3 . The avalanche multiplication layer 30 of undoped AlInAs material. Formed on the avalanche multiplication layer 30 with a film thickness of 0.01 to 0.1 μm and a carrier concentration of 0.1 to 1×10 18 cm -3 . The electric field adjustment layer 40 made of p-type InP material. On the electric field adjusting layer 40, an undoped light absorbing layer 51 of GaInAs...

Embodiment approach 2

[0076] Figure 11 is a cross-sectional view showing a schematic structure of an avalanche photodiode according to Embodiment 2 of the present invention. exist Figure 11 In Embodiment 1, the window layer 60 having a double-layer structure is formed with one layer of p-type window layer 63, an etching stop layer 160 is provided between the p-type window layer 63 and the light absorbing layer 50, and the p-type window layer 63 Except that island-shaped annular grooves 150 having a diameter of 20 to 100 μm and having a desired light-receiving size are provided thereon, it is the same as Embodiment 1, and thus detailed description thereof will be omitted.

[0077] Here, the p-type window layer 63 is an AlInAs material with a thickness of 0.5-2.0 μm, and a carrier concentration of 0.3-3×10 16 cm -3 ; The etch stop layer 160 has a film thickness of 0.01-0.05 μm and a carrier concentration of 0.3-3×10 16 cm -3 , n-type InP material. In addition, the carrier concentration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com