Preparation method of composite rod for improving performance of Nb3Sn superconducting composite wire

A composite rod and composite wire technology, which is applied in the usage of superconductor elements, superconductive devices, cable/conductor manufacturing, etc., can solve the problem of low proportion of Nb content in CuNb composite rods, low yield rate of wire rod processing, and easy production of Sn elements. Diffusion and other issues, to achieve the effect of increasing the proportion of Nb content, improving utilization, and avoiding coarse grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A way to improve Nb 3 A composite rod preparation method for Sn superconducting composite wire performance, the method specifically includes the following steps:

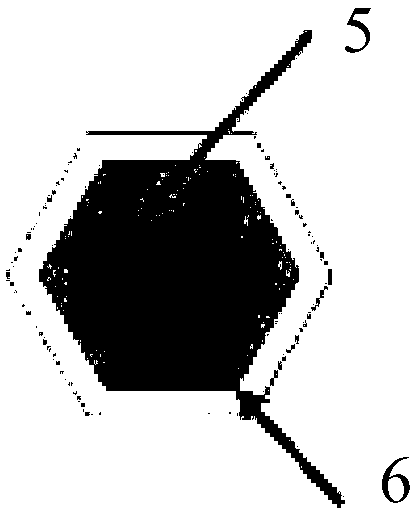

[0024] Step 1: Clean the Nb rod 5, wrap the Nb rod 5 with the copper layer 6 to obtain a CuNb single mandrel 4, the thickness of the copper layer 6 is 10 μm, and the length is 300 mm;

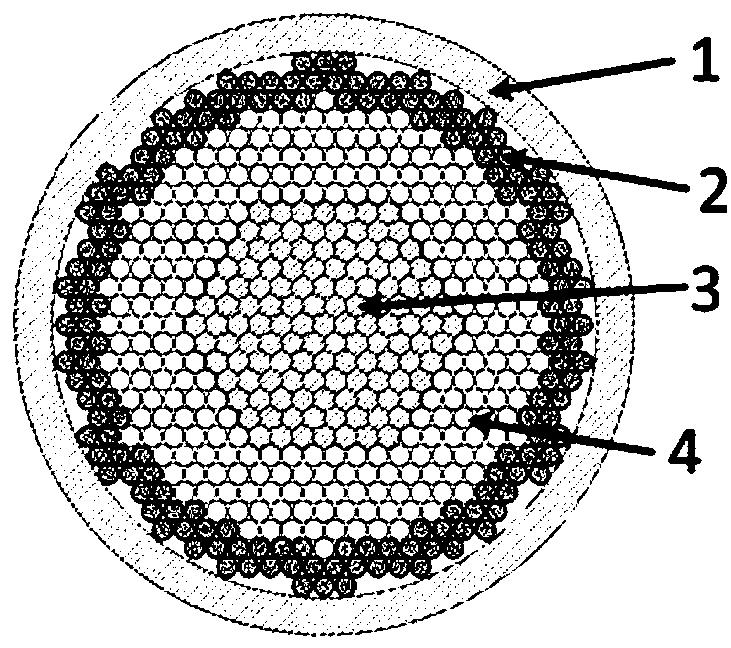

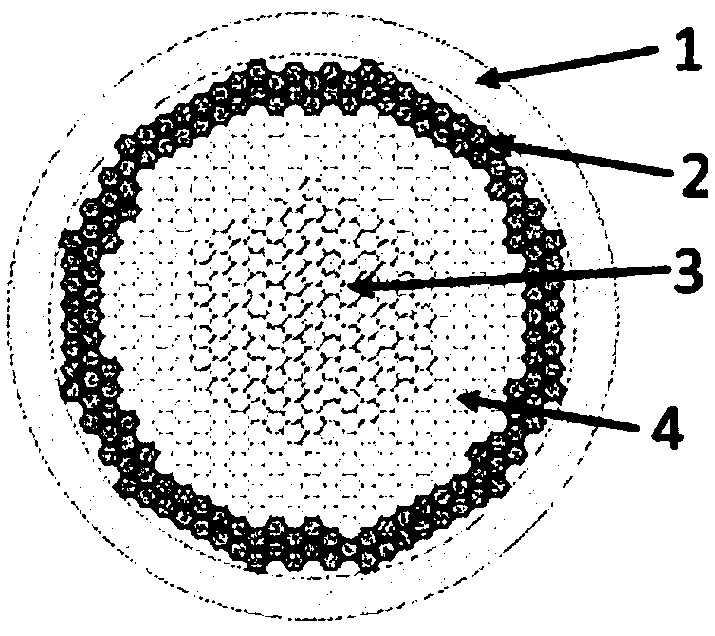

[0025] Step 2: Put the CuNb single mandrel 4, pure Nb rod 2, and hexagonal oxygen-free copper rod 3 in the step 1 into the oxygen-free copper sheath 1 according to the hexagonal arrangement, and the order from outside to inside is: oxygen-free copper sheath Set 1, pure Nb rod 2, CuNb single core rod 4, hexagonal oxygen-free copper rod 3, the specific process is to distribute CuNb single core rod 4 in the periphery of hexagonal oxygen-free copper rod 3, and CuNb single core rod 4 Redistribute the pure Nb rods 2 on the periphery and put them together into the oxygen-free copper sheath 1. The two ends are sealed and welded by va...

Embodiment 2

[0029] The difference from Example 1 is that in step 1 in this example, the way of wrapping the Nb rod 5 with the copper layer 6 is winding with oxygen-free copper foil.

Embodiment 3

[0031] A way to improve Nb 3 A composite rod preparation method for Sn superconducting composite wire performance, the method specifically includes the following steps:

[0032] Step 1: Clean the Nb rod 5, wrap the Nb rod 5 with the copper layer 6 to obtain a CuNb single mandrel 4, the thickness of the copper layer 6 is 300 μm, and the length is 800 mm;

[0033] Step 2: Put the CuNb single mandrel 4, pure Nb rod 2, and hexagonal oxygen-free copper rod 3 in the step 1 into the oxygen-free copper sheath 1 according to the hexagonal arrangement, and the order from outside to inside is: oxygen-free copper sheath Set 1, pure Nb rod 2, CuNb single core rod 4, hexagonal oxygen-free copper rod 3, the specific process is to distribute CuNb single core rod 4 in the periphery of hexagonal oxygen-free copper rod 3, and CuNb single core rod 4 Redistribute the pure Nb rods 2 on the periphery and put them together into the oxygen-free copper sheath 1. The two ends are sealed and welded by v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com