Method for preparing carbon cloth/tin flexible electrode material for negative electrode of sodium ion battery

A sodium-ion battery and flexible electrode technology, applied in battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve problems such as reducing battery efficiency and cycle performance, material powdering and falling off, and affecting the practical application of materials. Excellent electrochemical performance, increase energy density, and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

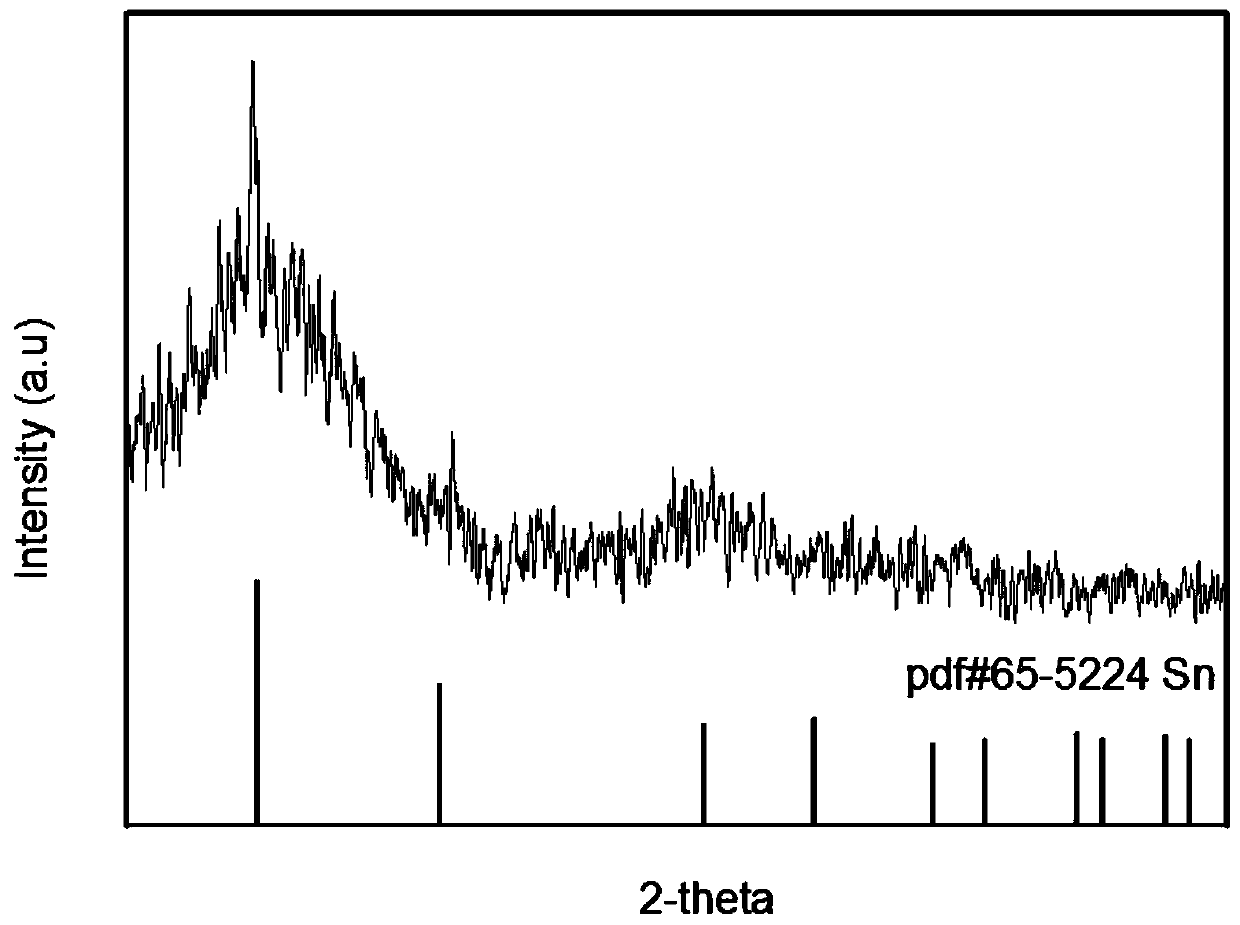

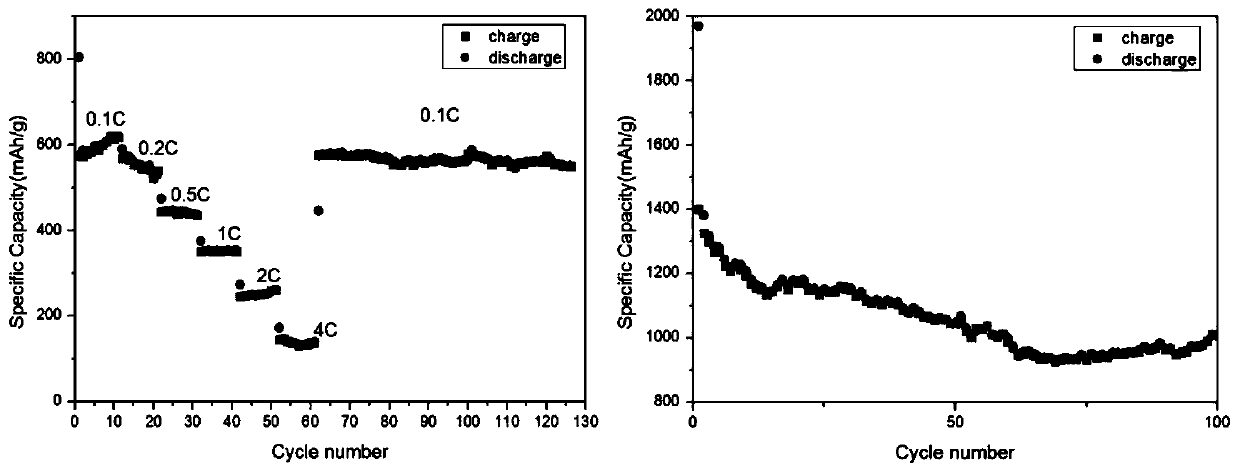

Embodiment 1

[0025] 1) Weigh 1.12g of PVP (molecular weight: 30000) and dissolve it in 20mL of ethanol, then add 0.47g of SnCl 2 2H 2 O to get the mixture (Sn 2+ The concentration is 0.01mol L -1 ), put the mixture into a microwave-ultrasonic synthesis extraction reaction apparatus (Shanghai Xinyi Microwave Chemical Technology Co., Ltd., Uwave-1000 type), turn on the ultrasonic mode, and ultrasonically 30min to make the PVP molecules and Sn 2+ After full effect, get solution A, add 5cm×5cm carbon cloth, and turn on the magnetic stirring device, control the rotor speed in solution A to 400r / min, stir for 1min;

[0026] 2) Add 5ml of hydrazine hydrate to solution A to obtain solution B, continue to stir for 5 minutes, take out the carbon cloth after stirring, and dry the carbon cloth in a vacuum drying oven at 60°C for 12 hours to obtain a carbon cloth / tin flexible electrode material ;

[0027] 3) Use the prepared carbon cloth / tin composite material as the negative electrode material of ...

Embodiment 2

[0029] 1) Weigh 1.12g of PVP (molecular weight: 30,000) and dissolve it in 20mL of ethanol, then add 0.64g of SnCl 2 2H 2 O to get the mixture (Sn 2+ The concentration is 0.013mol L -1 ), pour the mixture into a microwave-ultrasonic synthesis extraction reaction apparatus (Shanghai Xinyi Microwave Chemical Technology Co., Ltd., Uwave-1000 type), turn on the ultrasonic mode, and ultrasonically 30min to make PVP molecules and Sn 2+ After full effect, get solution A, add 4cm × 4cm carbon cloth, and turn on the magnetic stirring device, control the rotor speed in solution A to 500r / min, stir for 1min;

[0030] 2) Add 10ml of hydrazine hydrate to solution A to obtain solution B, continue to stir for 5 minutes, take out the carbon cloth after stirring, and dry the carbon cloth in a vacuum drying oven at 60°C for 12 hours to obtain a carbon cloth / tin flexible electrode material ;

[0031] 3) Use the prepared carbon cloth / tin composite material as the negative electrode material o...

Embodiment 3

[0036] 1) Weigh 2.24g of PVP (molecular weight: 30,000) and dissolve it in 50mL of ethanol, then add 0.72g of SnCl after dissolving 2 2H 2 O to get the mixture (Sn 2+ The concentration is 0.04mol L -1 ), pour the mixture into a microwave-ultrasonic synthesis extraction reaction apparatus (Shanghai Xinyi Microwave Chemical Technology Co., Ltd., Uwave-1000 type), turn on the ultrasonic mode, and ultrasonically 20min to make PVP molecules and Sn 2+ After full effect, obtain solution A, and turn on the magnetic stirring device, control the rotor speed in solution A to 800r / min, and stir for 10min;

[0037]2) Add 10ml of hydrazine hydrate to solution A to obtain solution B, continue to stir for 10 minutes, take out the carbon cloth after stirring, and dry the carbon cloth in a vacuum drying oven at 60°C for 6 hours to obtain a carbon cloth / tin flexible electrode material ;

[0038] 3) Use the prepared carbon cloth / tin composite material as the negative electrode material of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com