Oxidation-resistant SmCoX-Y(SiaGebSnc)Y high-temperature permanent-magnet material for aeroengine and preparation method thereof

A technology of aero-engines and permanent magnet materials, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of inability to store to room temperature, sample magnetic performance attenuation, etc., achieve good high-temperature oxidation resistance, and improve high-temperature oxidation resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

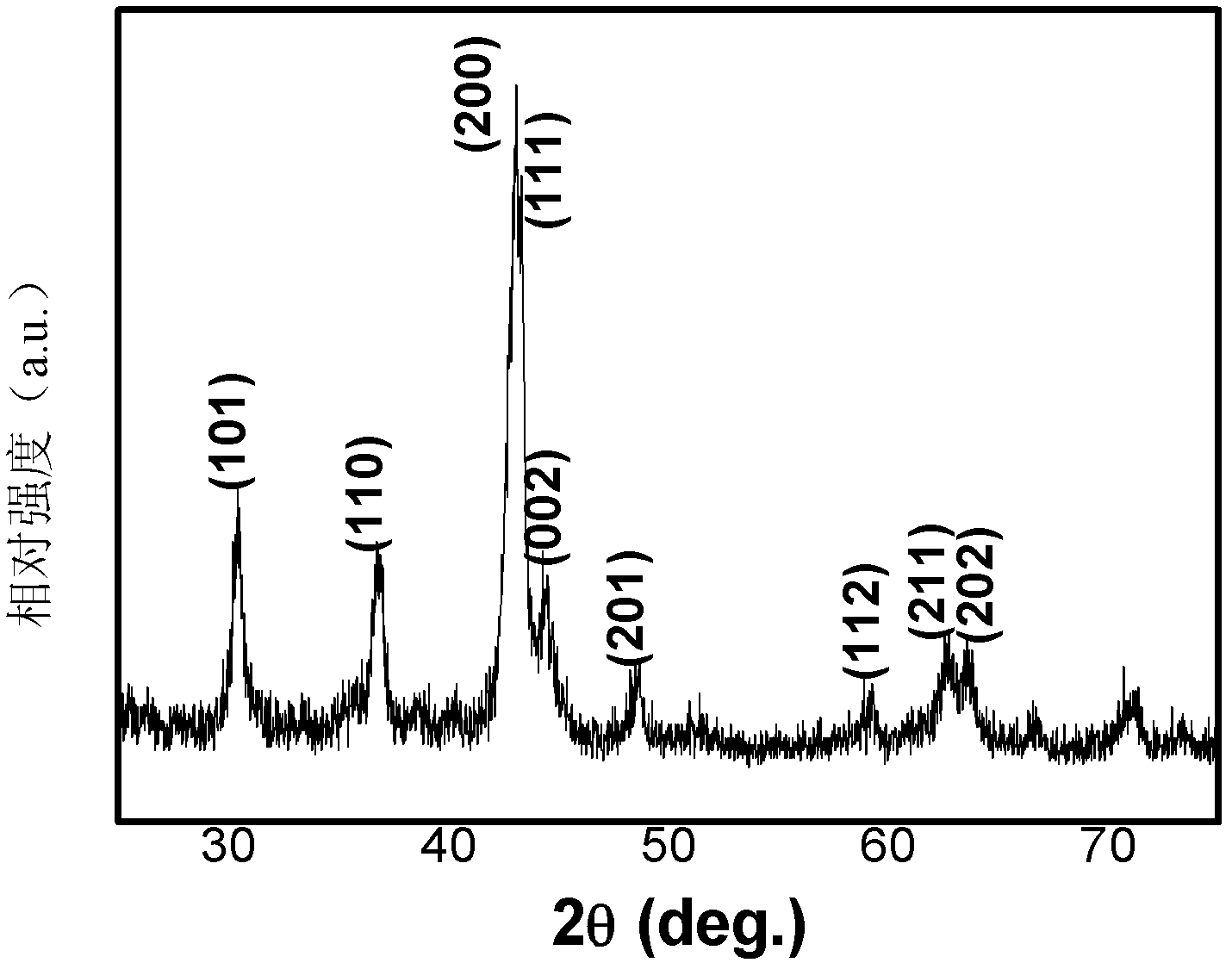

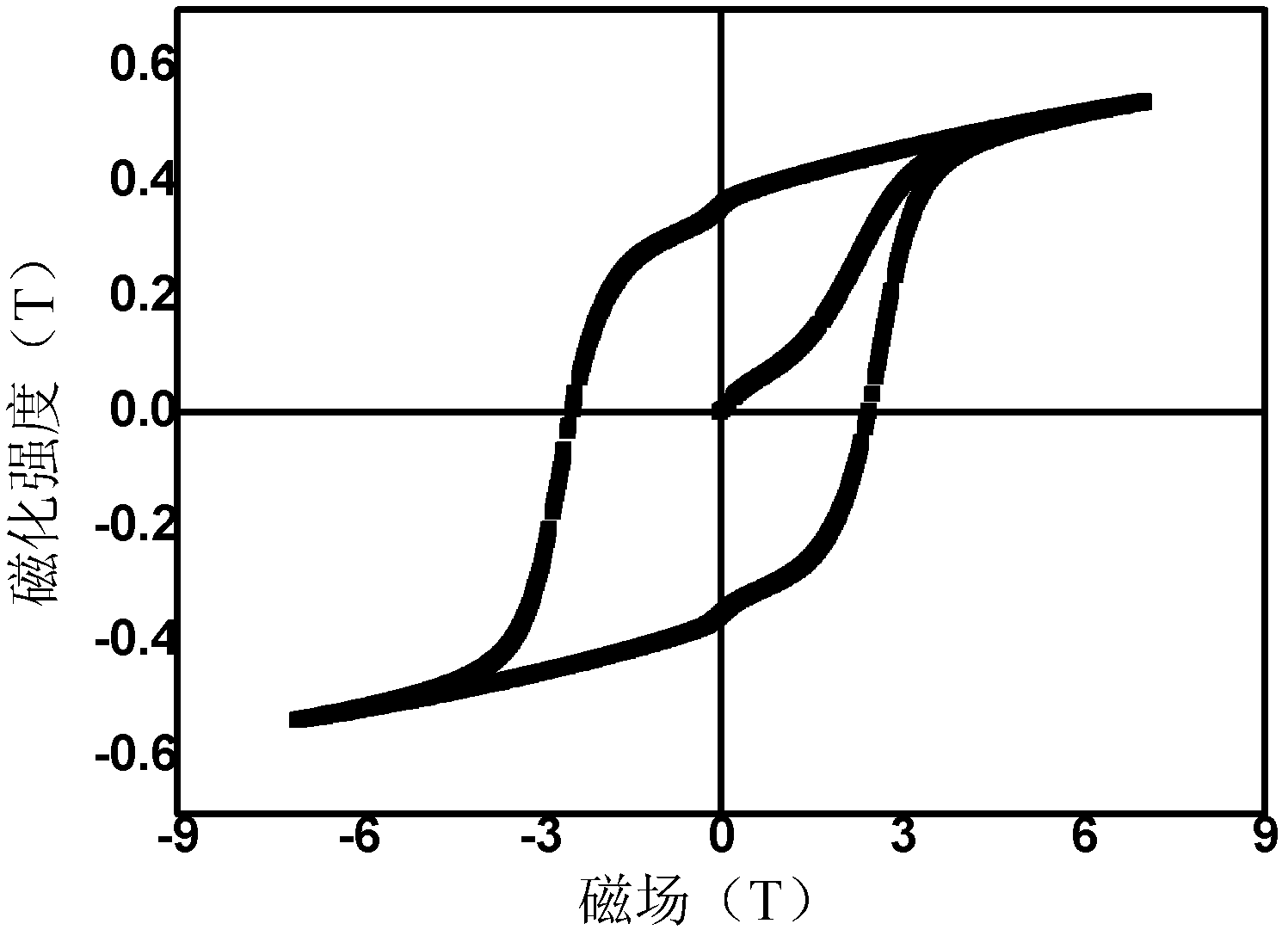

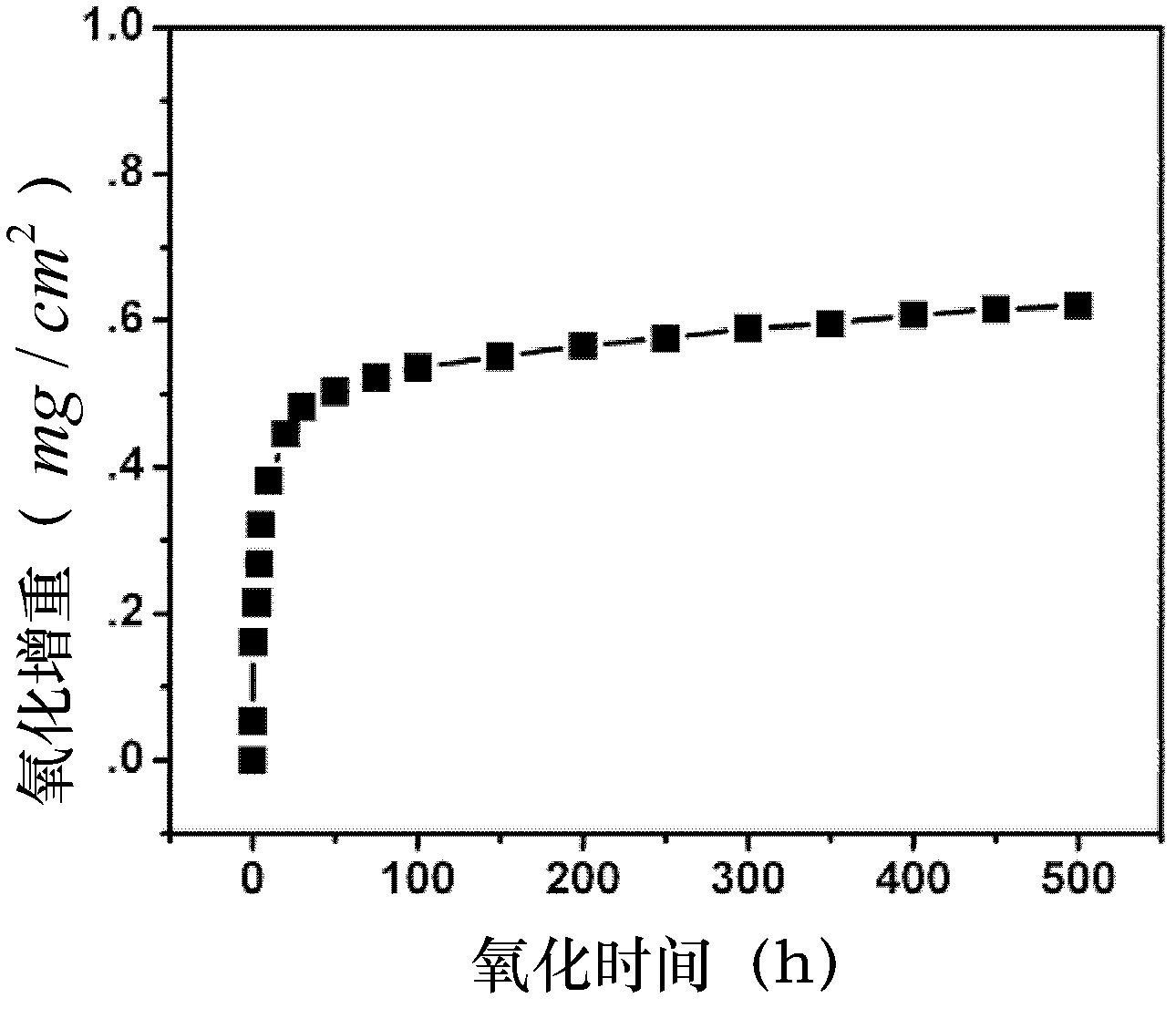

[0062] Example 1 Antioxidant SmCo 6.1 (Si 0.98 Ge 0.01 sn 0.01 ) 0.9 High temperature permanent magnet material

[0063] Step 1: Quaternary Alloy Preparation

[0064] Weigh Sm, Co, Si and Ge to configure the target composition;

[0065] Place the target components in a water-cooled copper crucible in a vacuum arc melting furnace;

[0066] Adjust the vacuum degree of the vacuum chamber to 3×10 -3 Pa, then fill high-purity (mass percent purity 99.999%) argon to make the vacuum of the vacuum chamber to 0.5 × 10 5 Pa;

[0067] After arc melting for 50s, the arc is broken to form the first alloy ingot;

[0068] Turn over the first alloy ingot, and after arc melting for 50s, break the arc to form the second alloy ingot;

[0069] Turn over the second alloy ingot, and after arc melting for 50s, break the arc to form the third alloy ingot; cool with the furnace, take it out, and make the SmCoSiGe quaternary alloy ingot;

[0070] In the present invention, the mass percent p...

Embodiment 2

[0091] Example 2 Antioxidant SmCo 8.1 (Si 0.7 Ge 0.2 sn 0.1 ) 0.5 High temperature permanent magnet material

[0092] Step 1: Quaternary Alloy Preparation

[0093] Weigh Sm, Co, Si and Ge to configure the target composition;

[0094] Place the target components in a water-cooled copper crucible in a vacuum arc melting furnace;

[0095] Adjust the vacuum degree of the vacuum chamber to 4×10 -3 Pa, then fill high-purity (mass percent purity 99.999%) argon to make the vacuum of the vacuum chamber to 0.7 × 10 5 Pa;

[0096] After arc melting for 70s, the arc is broken to form the first alloy ingot;

[0097] Flip the first alloy ingot, after arc melting for 60s, break the arc to form the second alloy ingot;

[0098] Turn over the second alloy ingot, and after arc melting for 50s, break the arc to form the third alloy ingot; cool with the furnace, take it out, and make the SmCoSiGe quaternary alloy ingot;

[0099] Turn over the third alloy ingot, and after arc melting f...

Embodiment 3

[0119] Example 3 Antioxidant SmCo 5.1 (Si 0.2 Ge 0.7 sn 0.1 ) 1.9 High temperature permanent magnet material

[0120] Step 1: Quaternary Alloy Preparation

[0121] Weigh Sm, Co, Si and Ge to configure the target composition;

[0122] Place the target components in a water-cooled copper crucible in a vacuum arc melting furnace;

[0123] Adjust the vacuum degree of the vacuum chamber to 5×10 -3 Pa, then fill high-purity (mass percent purity 99.999%) argon to make the vacuum of the vacuum chamber to 0.8 × 10 5 Pa;

[0124] After arc melting for 40s, the arc is broken to form the first alloy ingot;

[0125] Flip the first alloy ingot, after arc melting for 60s, break the arc to form the second alloy ingot;

[0126] Turn over the second alloy ingot, and after arc melting for 90s, break the arc to form the third alloy ingot; cool with the furnace, take it out, and make the SmCoSiGe quaternary alloy ingot;

[0127] In the present invention, the mass percent purity of Sm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com