Reduction preparation method of copper-based elastic alloy thin strip

An elastic alloy and weight reduction technology, which is applied in the field of reduction preparation of copper-based elastic alloy thin strips, to achieve the effects of reducing cold rolling reduction, reducing costs, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Smelt copper alloy according to the designed composition to obtain copper alloy melt, its composition contains Ni 9%, Sn 6%, impurity ≤ 0.05%, and the rest is Cu;

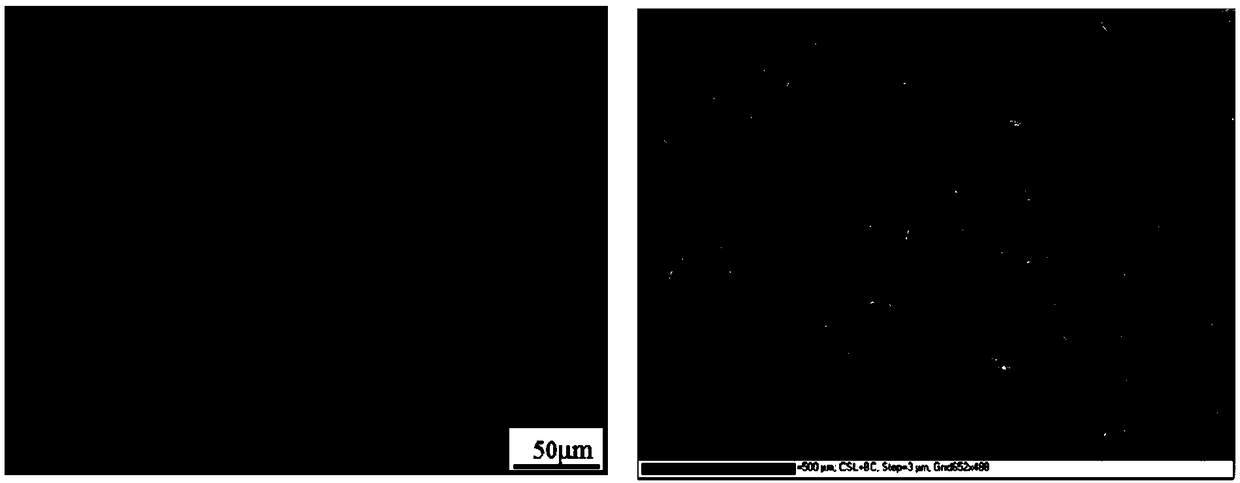

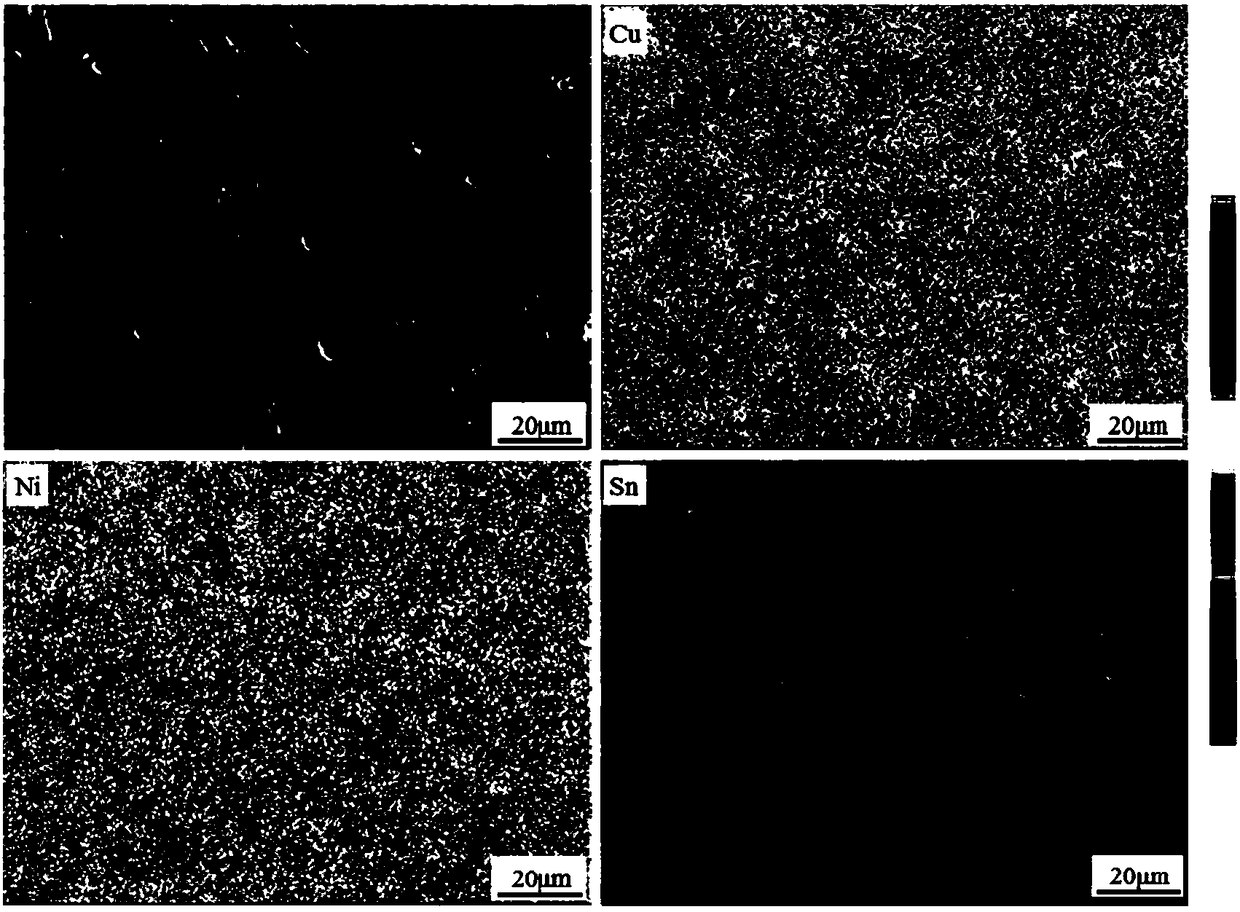

[0027] The copper alloy melt enters the tundish through the gate, the superheat is controlled at 15°C, the tundish preheating temperature is 1100°C, and then poured into a twin-roll thin strip casting machine for continuous casting to make a cast strip with a thickness of 2.0mm. The height of the liquid level is controlled at 50mm during casting, and the speed of the continuous casting rod is 35m / min; the casting strip is cooled by spraying water immediately after it comes out of the casting roll, the cooling speed is controlled at 35°C / s, and it is coiled at 400°C; the metallographic structure of the cast strip and Special twin boundary distribution such as figure 1 As shown, the cast strip structure element segregation distribution is as follows figure 2 As shown, it can be seen from the figure that the ...

Embodiment 2

[0031] Method is with embodiment 1, and difference is:

[0032] (1) The composition of the copper alloy melt contains 15% Ni and 8% Sn by mass percentage;

[0033] (2) Control superheat to 25°C, tundish preheating temperature to 1150°C, casting strip thickness to 3.0mm, control liquid level height to 100mm during continuous casting, continuous casting rod speed to 45m / min; control cooling after casting strip comes out of casting roll Speed 40℃ / s, coiling at 380℃;

[0034] (3) The total reduction rate of cold rolling is 95%; the thickness of cold rolling strip is 0.15mm;

[0035] (4) The aging treatment temperature is 450°C and the time is 2h. The tensile strength of the copper-based elastic alloy thin strip is 1327MPa, the electrical conductivity is 16.5%IACS, and the elastic specific work is 5.367GPa.

Embodiment 3

[0037] Method is with embodiment 1, and difference is:

[0038] (1) The composition of the copper alloy melt contains 7.5% Ni and 5% Sn by mass percentage;

[0039] (2) Control superheat to 20°C, tundish preheating temperature to 1200°C, casting strip thickness to 1.0mm, control liquid level height to 80mm during continuous casting, continuous casting rod speed to 40m / min; control cooling after casting strip comes out of casting roll Speed 45℃ / s, coiling at 350℃;

[0040] (3) The total reduction rate of cold rolling is 85%; the thickness of cold rolling strip is 0.15mm;

[0041] (4) The aging treatment temperature is 380°C and the time is 6h. The tensile strength of the copper-based elastic alloy thin strip is 1050MPa, the electrical conductivity is 18.2%IACS, and the elastic specific work is 4.567GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com