Preparation method of SnS3 nano powder

A nano-powder and powder technology, which is applied in the field of SnSe nano-powder preparation, can solve the problems of reactants being oxidized and reactants not fully reacting, and achieve the effects of short synthesis time, strong practicability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

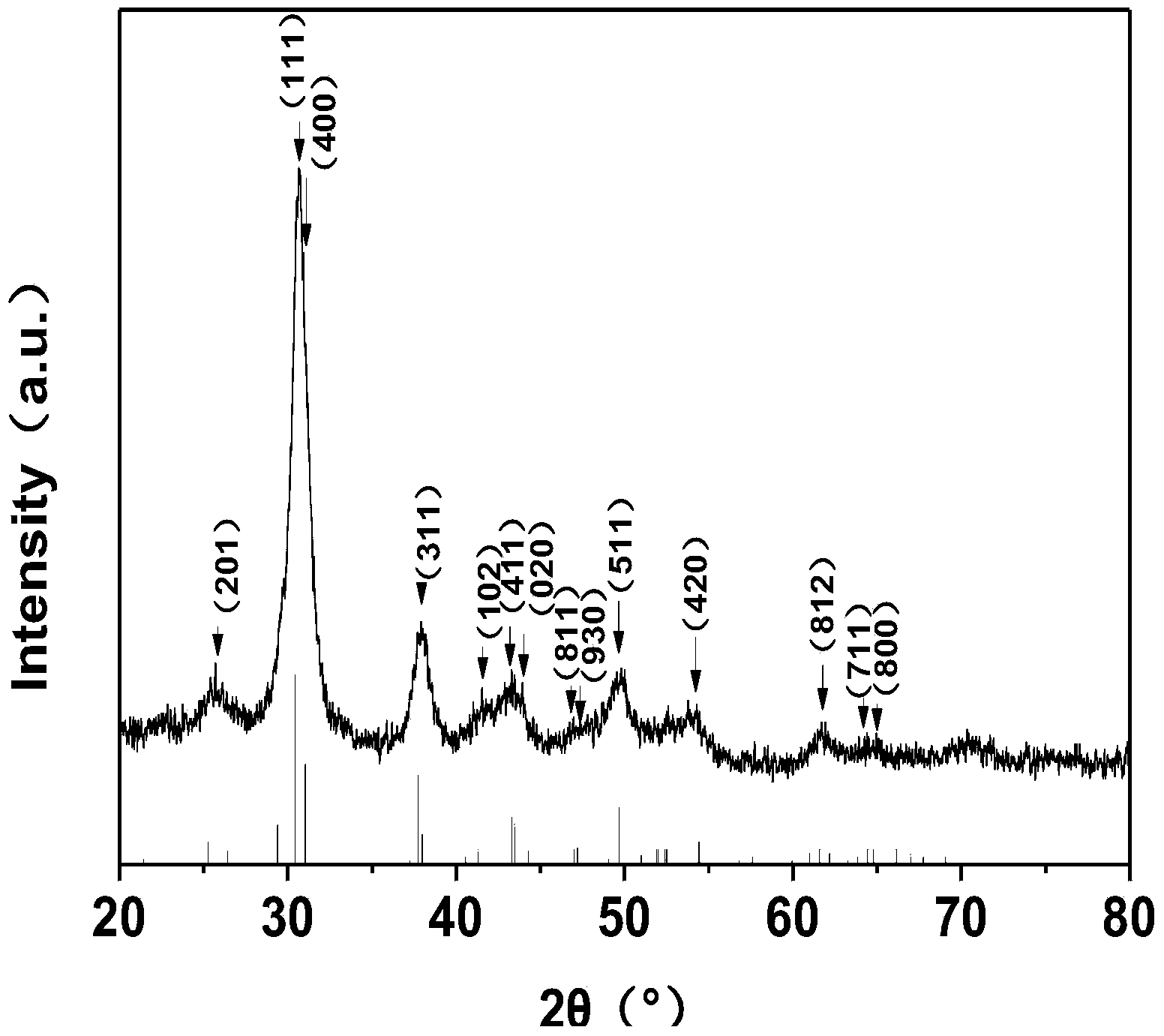

[0015] The invention provides a preparation method of SnSe nano powder. In the preparation method, a mechanical alloying method is adopted. First, the high-purity Sn and Se elemental powders are mixed according to the atomic ratio of 1:1, and put together into a planetary ball mill. Mechanical alloying is carried out under the protection of inert gas (argon), the synthetic compound is dry-milled, then wet-milled, and finally dried to obtain SnSe powder.

[0016] Table 1 has provided and adopted preparation method provided by the present invention, prepares several preferred embodiments of SnSe powder:

[0017] Table 1

[0018] Optimal practice

Mechanical Alloying Dry Grinding

Mechanical Alloying Wet Grinding

whether

particle size

[0019] Example

speed(rpm)

time (h)

speed(rpm)

time (min)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com