method for preparing CTS or CTSSe film

A copper-tin-sulfur and thin-film technology, which is applied in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as limited fossil fuel reserves, achieve simple preparation equipment and processes, and large-area uniform preparation , the effect of low cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

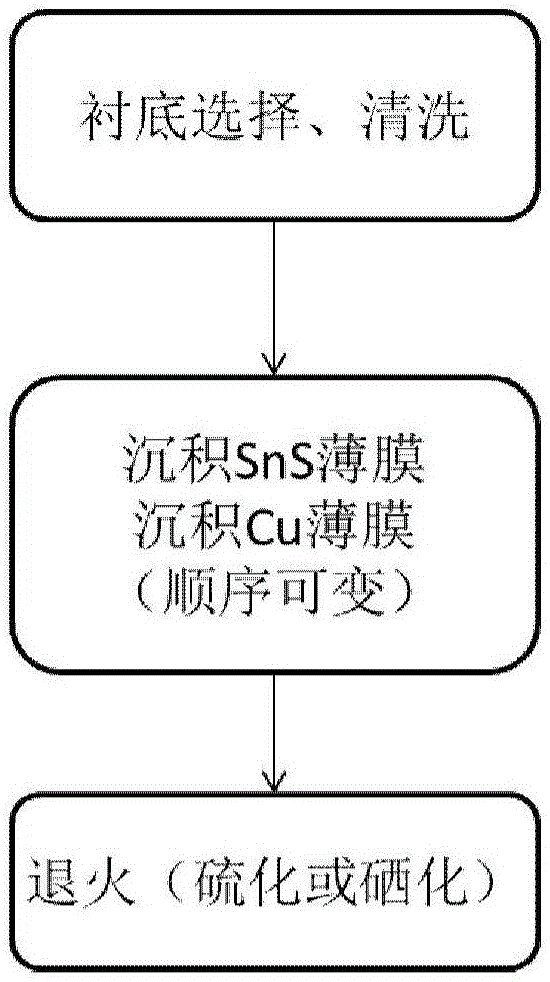

[0053] In some specific embodiments of the present disclosure, the preparation method of the CTS or CTSSe film involved in the present disclosure is achieved through the following technical solutions, specifically including the following steps:

[0054] 1) First, the substrate is cleaned: the substrate is immersed in ethanol and ammonia solution in sequence, then deionized water is ultrasonically oscillated and rinsed, and blown dry with nitrogen.

[0055] 2) Depositing a layer of SnS thin film by chemical solution deposition on the surface of the clean substrate obtained in step 1); wherein the deposition solution is a mixed solution comprising stannous salt, complexing agent, sulfur-containing compound and an alkaline solution for adjusting pH; The concentration of the stannous salt in the mixed solution is 0.02-0.06M, the volume fraction of the complexing agent is 2%-8%, the concentration of the sulfur-containing compound is 0.06-0.12M, and the pH is adjusted to 10-14 with a...

Embodiment 1

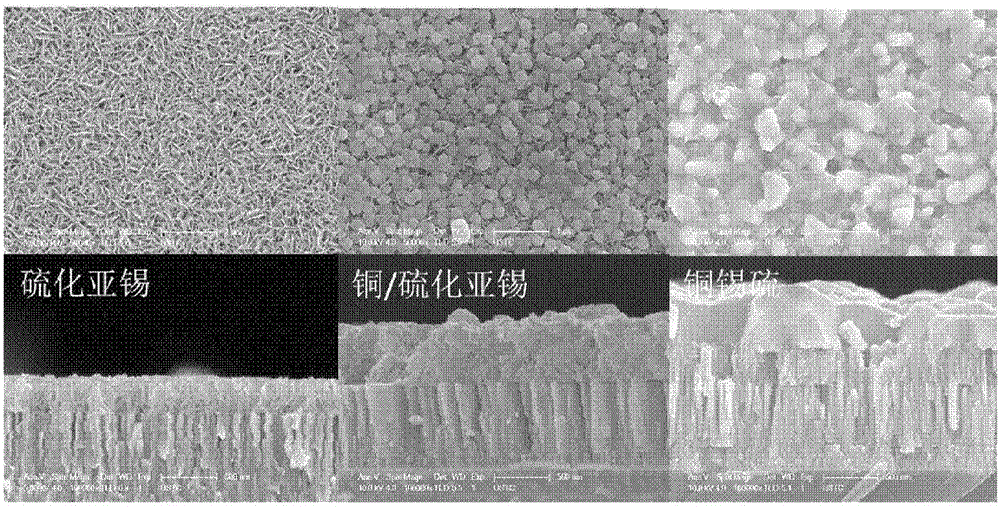

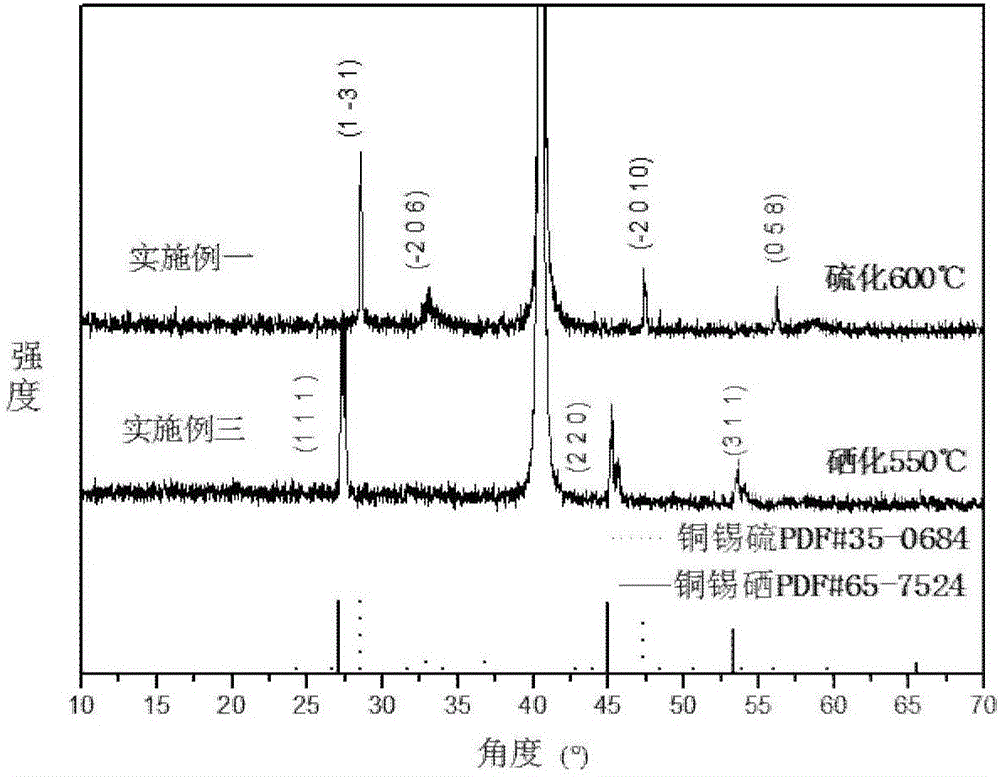

[0069] Example 1: Preparation of thin films based on CTS (substrate / SnS / Cu stacking sequence)

[0070] 1) Clean the molybdenum-coated glass substrate first: immerse the substrate in ethanol and ammonia solution in sequence, then deionized water for ultrasonic vibration and rinse, and blow dry with nitrogen.

[0071] 2) on the surface of the clean molybdenum substrate obtained in step 1), chemical solution deposition deposits a layer of SnS thin film; the molybdenum substrate is vertically placed in a 30ml vial, and the deposition solution is configured: 1g of analytically pure stannous chloride ( SnCl 2 2H 2 O) add 5ml absolute ethanol to dissolve, then add 3ml28% ammoniacal liquor, add 12ml50% triethanolamine after 5s as complexing agent and the 1M thioacetamide of 8ml (C 2 h 5 NS) as a sulfur source, the concentration of tin protochloride in the deposition solution is 0.044M, the volume fraction of triethanolamine is 6%, the concentration of thioacetamide is 0.08M, and th...

Embodiment 2

[0074] Example 2: Preparation of thin films based on CTS (substrate / Cu / SnS stacking sequence)

[0075] 1) Clean the molybdenum-coated glass substrate first: immerse the substrate in ethanol and ammonia solution in sequence, then ultrasonically rinse with deionized water, and blow dry with nitrogen.

[0076] 2) On the surface of the clean molybdenum substrate obtained in step 1), chemical solution deposition deposits a layer of Cu thin film; the molybdenum substrate is vertically placed in a 30ml vial, and the deposition solution is configured; take a 100ml beaker, and first take a concentration of 0.5 M copper sulfate (CuSO 4 ·5H 2 O) 13ml, reducing agent sodium ascorbate (C 6 h 7 o 6 Na) 0.5M7ml joins in the beaker, utilizes stirring bar to stir, the time is 30s, then the complexing agent trisodium citrate of 0.5M (C 6 h 7 o 5 Na 3 2H 2 (2) 13ml is added wherein rapidly, after stirring 90s, add the 28% ammoniacal liquor of 0.7ml, add deionized water to 60ml, at this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com