Diffusion welding method of copper alloy and stainless steel

A stainless steel and copper alloy technology, applied in the field of diffusion welding, can solve problems such as low joint strength, reduce the overall cost, increase the effective welding area, and improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

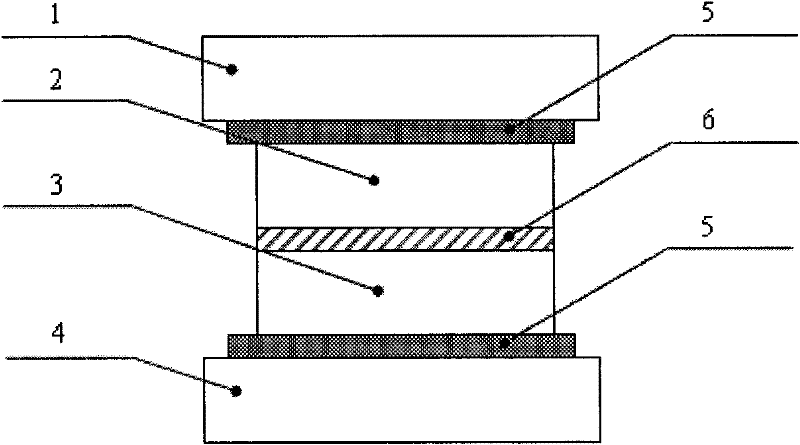

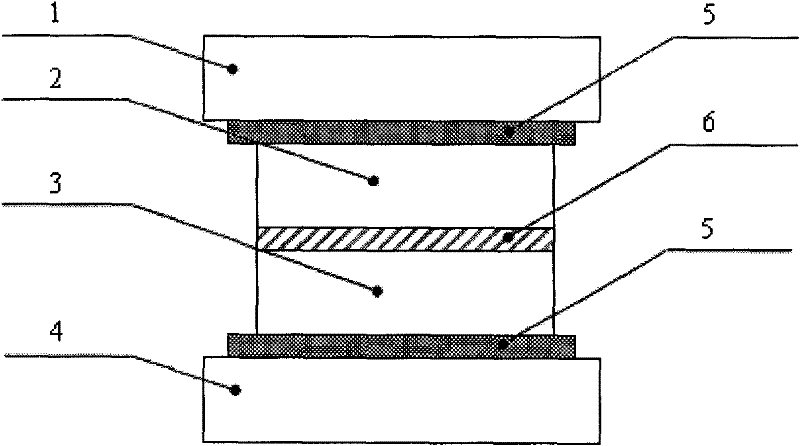

[0017] Example 1: Diffusion welding of T2 copper alloy and 1Cr18Ni9Ti stainless steel.

[0018] Tin bronze QSn6.5-0.1 foil material 6 with a thickness of 0.1 mm is used as the connecting material for the intermediate layer. use 2000 # The surface of the QSn6.5-0.1 foil 6 and the surface to be welded of the T2 copper alloy 2 and the 1Cr18Ni9Ti stainless steel 3 were polished with SiC sandpaper. Then immerse QSn6.5-0.1 foil 6, T2 copper alloy 2 and 1Cr18Ni9Ti stainless steel 3 in acetone solution, ultrasonically clean for 5 minutes, and dry with cold air. The above materials are clamped: the QSn6.5-0.1 foil material 6 is placed between the T2 copper alloy 2 and the 1Cr18Ni9Ti stainless steel 3 . Put the workpiece to be welded into the vacuum furnace, and place it between the upper indenter 1 and the lower indenter 4 in the vacuum diffusion welding furnace, between the upper indenter 1 and T2 copper alloy 2, the lower indenter 4 and 1Cr18Ni9Ti stainless steel 3 A solder mask l...

Embodiment 2

[0020] Example 2: Diffusion welding of H96 copper alloy and 00Cr19Ni10 stainless steel.

[0021] Tin bronze QSn7-0.2 foil material 6 with a thickness of 0.1mm is used as the connecting material of the intermediate layer. use 2000 # The surface of the QSn7-0.2 foil 6 and the surface to be welded of the H96-Cu copper alloy 2 and the 00Cr19Ni10 stainless steel 3 were polished with SiC sandpaper. Then immerse QSn7-0.2 foil 6, H96 copper alloy 2 and 00Cr19Ni10 stainless steel 3 in acetone solution, ultrasonically clean for 5 minutes, and dry with cold air. The above materials are clamped: the QSn7-0.2 foil material 6 is placed between the H96 copper alloy 2 and the 00Cr19Ni10 stainless steel 3 . Put the workpiece to be welded into the vacuum furnace, and place it between the upper indenter 1 and the lower indenter 4 in the vacuum diffusion welding furnace, between the upper indenter 1 and H96 copper alloy 2, the lower indenter 4 and 00Cr19Ni10 stainless steel 3 A solder mask lay...

Embodiment 3

[0023] Embodiment 3: Diffusion welding of QSn4-0.3 copper alloy and 0Cr17Ni12Mo2 stainless steel.

[0024] Tin bronze QSn8-0.3 foil material 6 with a thickness of 0.1mm is used as the connecting material of the intermediate layer. use 2000 # The surface of the QSn8-0.3 foil 6 and the surface of the QSn4-0.3 copper alloy 2 and the 0Cr17Ni12Mo2 stainless steel 3 to be welded were polished with SiC sandpaper. Then immerse QSn8-0.3 foil 6, QSn4-0.3 copper alloy 2 and 0Cr17Ni12Mo2 stainless steel 3 in acetone solution, ultrasonically clean for 5 minutes, and dry with cold air. The above materials are clamped: the QSn8-0.3 foil material 6 is placed between the QSn4-0.3 copper alloy 2 and the 0Cr17Ni12Mo2 stainless steel 3 . Put the workpiece to be welded into the vacuum furnace, and place it between the upper indenter 1 and the lower indenter 4 in the vacuum diffusion welding furnace. 3 place a solder resist layer 5 between them. Apply a pre-pressure of 0.5MPa to the workpiece t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com