Infrared night-vision goggle based on GeSn infrared detector

A technology of infrared detectors and night vision devices, applied in the field of microelectronics, can solve the problems of restricting the photosensitive efficiency, limiting the sensitivity and photosensitive efficiency of infrared night vision devices, and achieve the effects of improving photosensitive efficiency, expanding the absorption wavelength range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

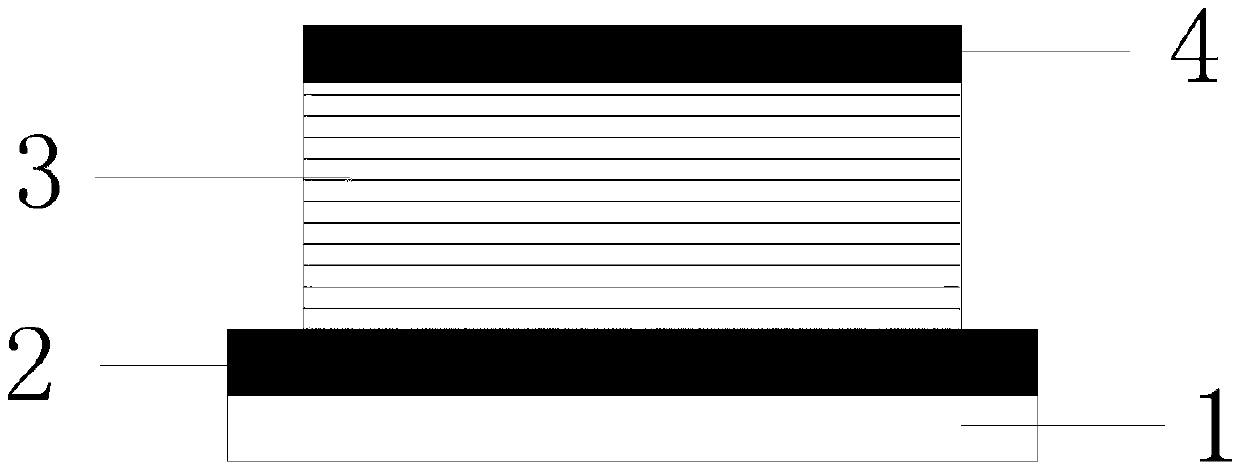

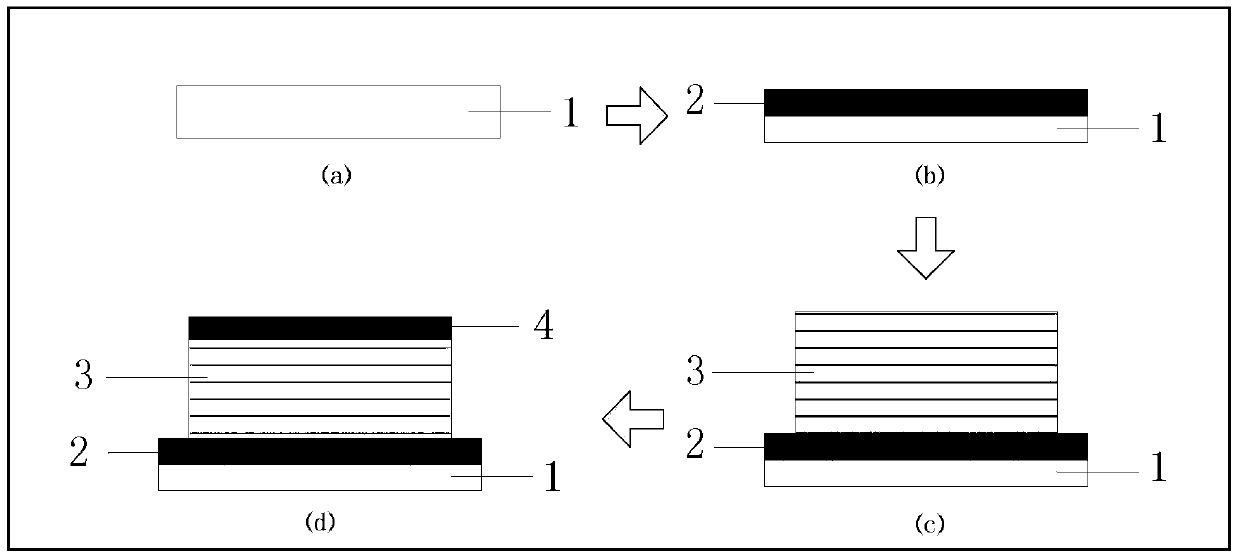

[0033] Embodiment 1: Fabrication of a GeSn infrared detector with a Sn composition of 0 and a Ge composition of 1 in the absorption zone.

[0034] Step 1: Using ion implantation, the implantation dose in Si substrate 1 is 10 15 cm -2 , The phosphorus element with energy of 20KeV forms the N-type bottom electrode 2, such as image 3 b.

[0035] Step 2: Using molecular beam epitaxy process, on the bottom electrode 2, solid Ge and Sn are used as evaporation sources, and 10 -4 At the pressure of pa, the relaxed intrinsic GeSn single crystal is grown at 180℃, in which the Sn composition is 0 and the Ge composition is 1, forming an absorption zone 3, such as image 3 c.

[0036] Step 3: Using ion implantation, the implant dose is 10 in the top of GeSn material 15 cm -2 , Boron with an energy of 20KeV, form a P-type electrode 4 in the area where boron is implanted, such as image 3 d.

Embodiment 2

[0037] Embodiment 2: Fabrication of a GeSn infrared detector with a Sn composition of 0.10 and a Ge composition of 0.90 in the absorption zone.

[0038] Step 1: ion implantation to form the bottom electrode

[0039] The implant dose in Ge substrate 1 is 10 15 cm -2 , The phosphorus element with energy of 20KeV forms the N-type bottom electrode 2, such as image 3 b.

[0040] Step 2: Epitaxial relaxation of intrinsic GeSn single crystal

[0041] Using molecular beam epitaxy process, on the bottom electrode 2, solid Ge and Sn are used as evaporation sources, and 10 -4 The pressure of pa, at 180℃, the growth of a relaxed intrinsic GeSn single crystal, where the Sn composition is 0.10, and the Ge composition is 0.90, such as image 3 c.

[0042] Step 3: Ion implantation to form the upper electrode

[0043] Using ion implantation, the implant dose in the top of GeSn material is 10 15 cm -2 , Boron with an energy of 20KeV, forming a P-type electrode 4 in the area where boron is implanted, su...

Embodiment 3

[0044] Embodiment 3: Making a GeSn infrared detector with a Sn composition of 0.25 and a Ge composition of 0.75 in the absorption zone.

[0045] Step A: Using ion implantation, the implantation dose in the SOI substrate 1 is 10 15 cm -2 , The phosphorus element with energy of 20KeV forms the N-type bottom electrode 2, such as image 3 b.

[0046] Step B: Using the molecular beam epitaxy process, on the bottom electrode 2, solid Ge and Sn are used as evaporation sources, and 10 -4 The pressure of pa, at 180℃, the growth of a relaxed intrinsic GeSn single crystal, where the Sn composition is 0.25 and the Ge composition is 0.75, such as image 3 c.

[0047] Step C: Using ion implantation, the implant dose is 10 in the top of GeSn material 15 cm -2 , Boron with an energy of 20KeV, forming a P-type electrode 4 in the area where boron is implanted, such as image 3 d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com