Ti-Zr-Cu-Co-M alloy brazing filler metal and preparing method thereof

An alloy solder, ti-zr-cu-co-m technology, applied in the field of titanium alloy materials, can solve the problems of reducing the performance of brazed joints, achieve the effects of improving mechanical properties, reducing precipitation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

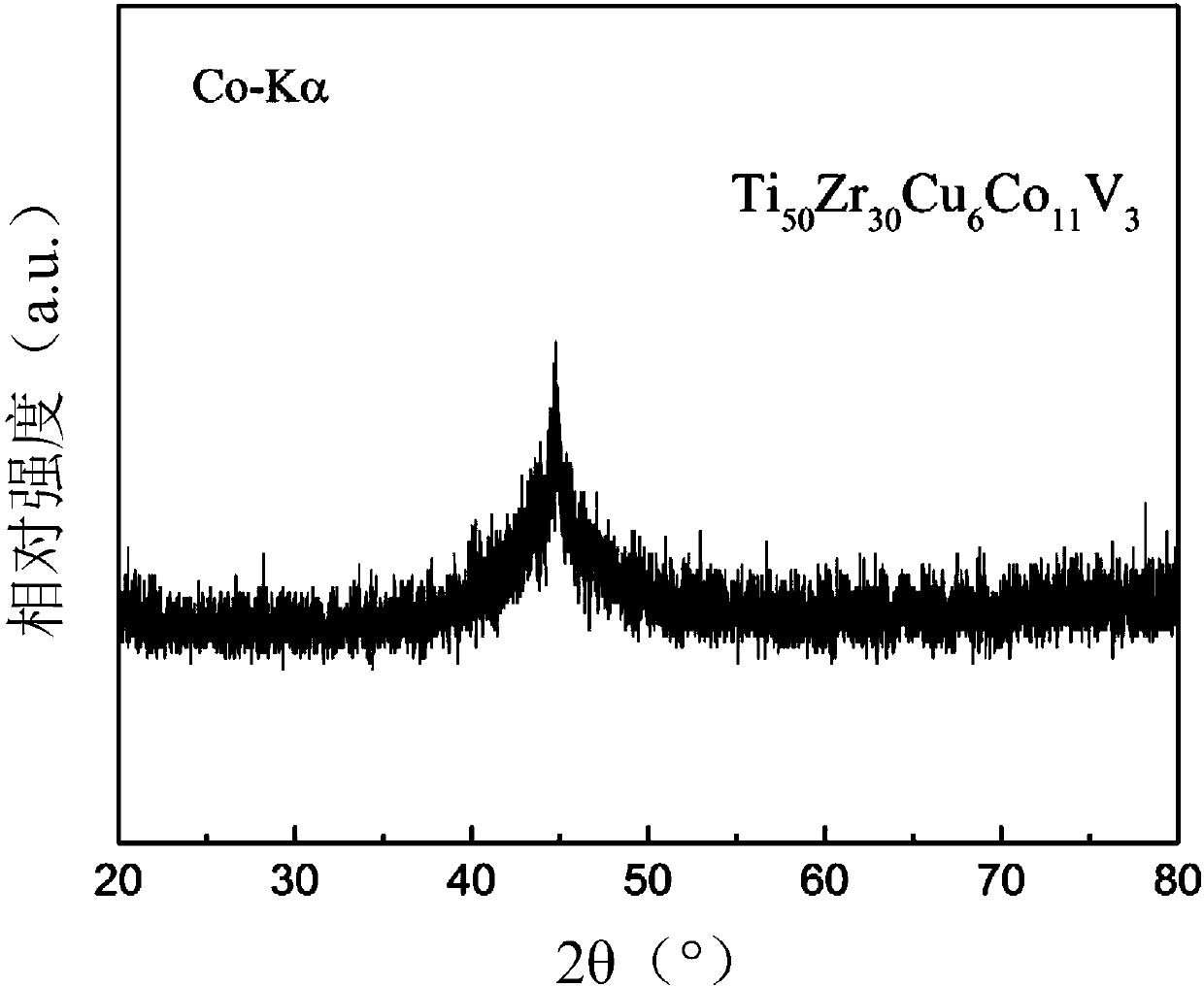

[0059] The target composition is: 37.92wt% Ti, 43.35wt% Zr, 6.04wt% Cu, 10.27wt% Co and 2.42wt% V. Namely Ti 50 Zr 30 Cu 6 co 11 V 3 . (atomic percent);

[0060] Preparation of Ti 50 Zr 30 Cu 6 co 11 V 3 The steps of alloy solder are:

[0061] Step 1: Weigh the simple substances of each element

[0062] According to the target solder composition Ti 50 Zr 30 Cu 6 co 11 V 3 Weigh the corresponding quality metal elemental raw materials, Ti, Zr, Cu, Co and V;

[0063] Step 2, smelting to prepare master alloy

[0064] Put the Ti, Zr, Cu, Co, V metal elemental raw materials weighed in step 1 into the vacuum arc melting equipment, and evacuate to 8×10 -3 Pa, filled with high-purity argon as a protective gas, the pressure in the furnace is 0.05MPa; the arc heating method is used to smelt repeatedly at least 4 times to ensure that the composition of the master alloy is uniform, the melting current is 180A, and the master alloy is taken out after the alloy is cooled w...

Embodiment 2

[0082] The target composition is: 29.92wt% Ti, 54.28wt% Zr, 1.89wt% Cu, 13.15wt% Co and 0.76wt% V. Namely Ti 42 Zr 40 Cu 15 co 2 V 1 . (atomic percent);

[0083] Preparation of Ti 42 Zr 40 Cu 15 co 2 V 1 The steps of alloy solder are:

[0084] Step 1: Weigh the simple substances of each element

[0085] According to the target solder composition Ti 42 Zr 40 Cu 15 co 2 V 1 Weigh the corresponding quality metal elemental raw materials, Ti, Zr, Cu, Co and V;

[0086] Step 2, smelting to prepare master alloy

[0087] Put the Ti, Zr, Cu, Co, V metal elemental raw materials weighed in step 1 into the vacuum arc melting equipment, and evacuate to 8×10 -3 Pa, filled with high-purity argon as a protective gas, the pressure in the furnace is 0.05MPa; the arc heating method is used to repeatedly smelt at least 4 times to ensure that the composition of the master alloy is uniform, and the melting current is 150A. After the alloy is cooled with the furnace, the master al...

Embodiment 3

[0100] The target composition is: 34.92wt% Ti, 41.95wt% Zr, 9.07wt% Cu, 8.41wt% Co and 5.65wt% V. Namely Ti 46 Zr 29 Cu 9 co 9 V 7 . (atomic percent);

[0101] Preparation of Ti 46 Zr 29 Cu 9 co 9 V 7 The steps of alloy solder are:

[0102] Step 1: Weigh the simple substances of each element

[0103] According to the target solder composition Ti 46 Zr 29 Cu 9 co 9 V 7 Weigh the corresponding quality metal elemental raw materials, Ti, Zr, Cu, Co and V;

[0104] Step 2, smelting to prepare master alloy

[0105] Put the Ti, Zr, Cu, Co, V metal elemental raw materials weighed in step 1 into the vacuum arc melting equipment, and evacuate to 8×10 -3 Pa, filled with high-purity argon as a protective gas, the pressure in the furnace is 0.05MPa; the arc heating method is used to repeatedly smelt at least 4 times to ensure that the composition of the master alloy is uniform, and the melting current is 150A. After the alloy is cooled with the furnace, the master alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidus temperature | aaaaa | aaaaa |

| Liquidus temperature | aaaaa | aaaaa |

| Liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com