Structure-optimized silver-doped Cu-Zn-Sn sulfur thin film solar cell and preparation method thereof

A thin-film solar cell, copper-zinc-tin-sulfur technology, applied in the field of solar cells, can solve the problems of poor compactness and poor adhesion of Ag-doped CZTS, and achieve the effects of reducing interface recombination, reducing pores, and improving crystallinity and compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of the silver-doped copper-zinc-tin-sulfur absorption layer includes two steps: the first step is to sputter various metal elements by magnetron sputtering to form a stack, commonly known as: prefabricated layer. In the second step, the prefabricated layer is placed in sulfur vapor at high temperature to undergo a chemical reaction to form a new substance, silver-doped copper-zinc-tin-sulfur. The gist of this paper is to adopt an optimized metal stack structure to facilitate the uniform fusion of various elements, thereby forming high-quality silver-doped copper-zinc-tin-sulfur.

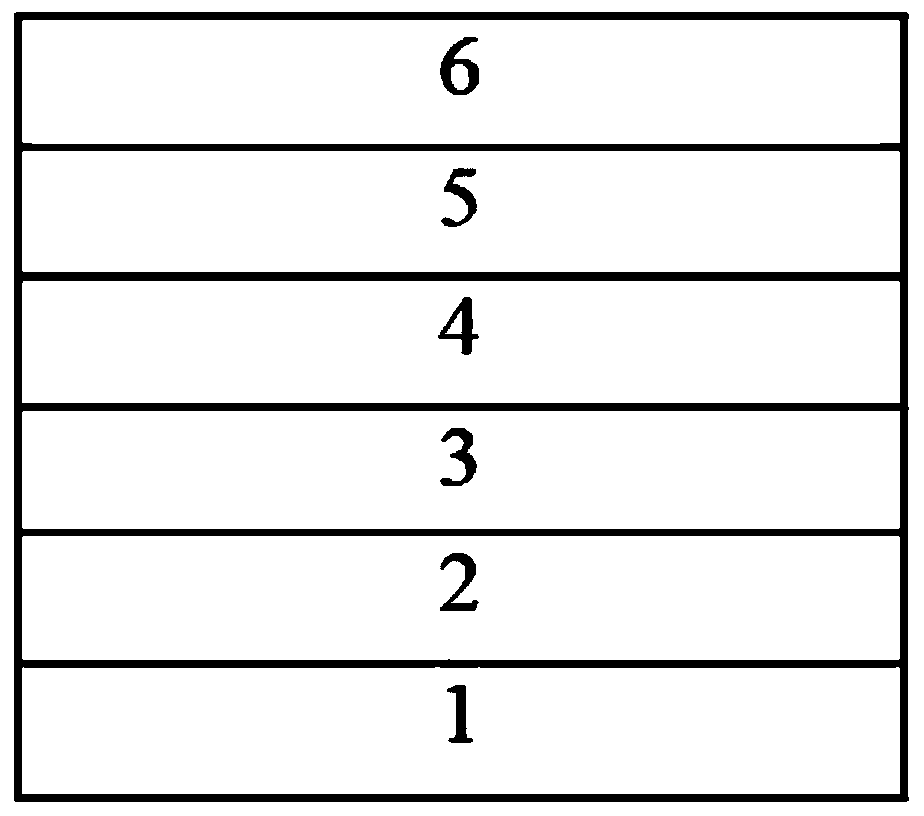

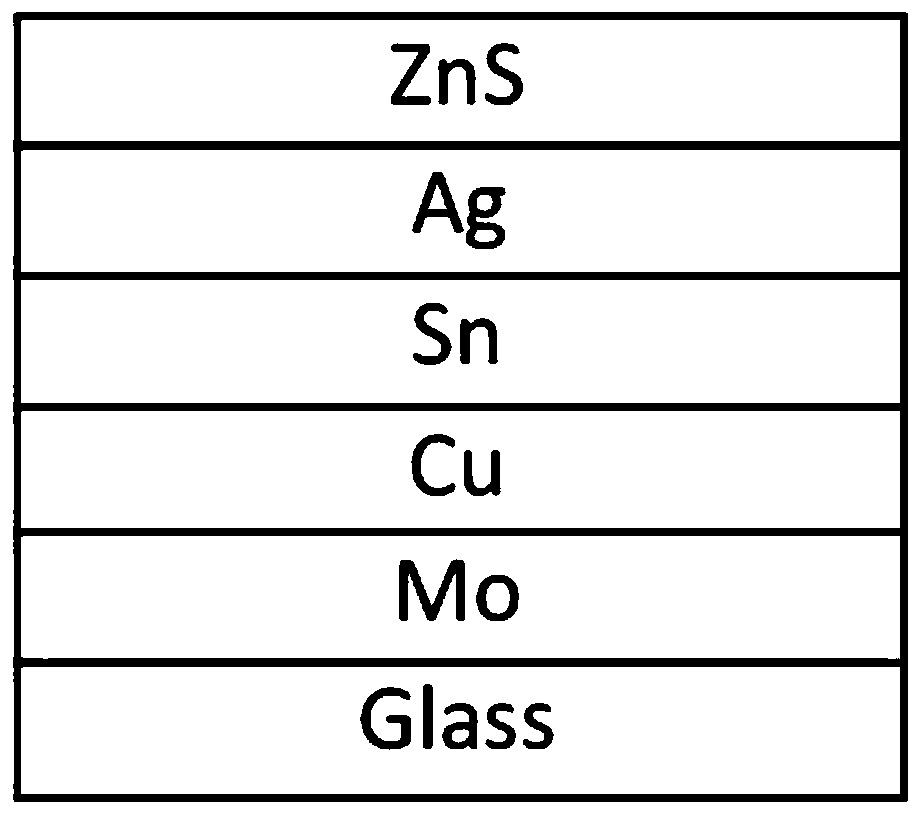

[0035] to combine figure 1 , figure 2 The silver-doped zinc-tin-sulfur thin film solar cell of the present invention comprises a glass substrate 1, a back electrode 2, an absorption layer 3, a buffer layer 4, a transparent conductive window layer 5 and an upper electrode 6 connected in sequence from bottom to top. The back electrode is a Mo film with a thickness of 1...

Embodiment 1

[0040] (1) Substrate cleaning: Clean the soda-lime glass with decontamination powder and washing powder in turn, and then put it into alcohol and acetone and ultrasonically for 30 minutes each. Afterwards, rinse with deionized water for 3~4 times, and use No. 1 solution (ammonia: hydrogen peroxide: water = 1:2:5) and No. 2 solution (hydrochloric acid: hydrogen peroxide: water = 1:2:8) to heat Boil for 10 minutes. Finally, after the sample was cooled, it was rinsed with deionized water and dried with nitrogen;

[0041] (2) Put the cleaned sample into the magnetron sputtering chamber and evacuate to 5×10 -4 pa. Then pass high-purity argon gas with a gas flow rate of 5.5 sccm as the working gas. Adjust the rotation speed of the substrate table to 8.0rpm. The double-layer Mo film with high and low resistance layers was sputtered by DC method as the back electrode. Firstly, the Mo film with high resistance layer was sputtered, the sputtering power was 200W, the working pressure...

Embodiment 2

[0049] Observe whether it meets expectations after increasing the vulcanization temperature.

[0050] The difference between Example 2 and Example 1 is that the vulcanization temperature of Example 1 is 560° C., and the vulcanization temperature of Example 2 is 580° C. Excessive temperature will generally accelerate the decomposition of copper, zinc, tin and sulfur and increase the loss of elements, from Figure 9 , Figure 10 A small amount of holes can be seen, indicating that the loss of elements is not obvious. To a certain extent, it shows that the doping of Ag has a significant effect on reducing the loss of Sn elements.

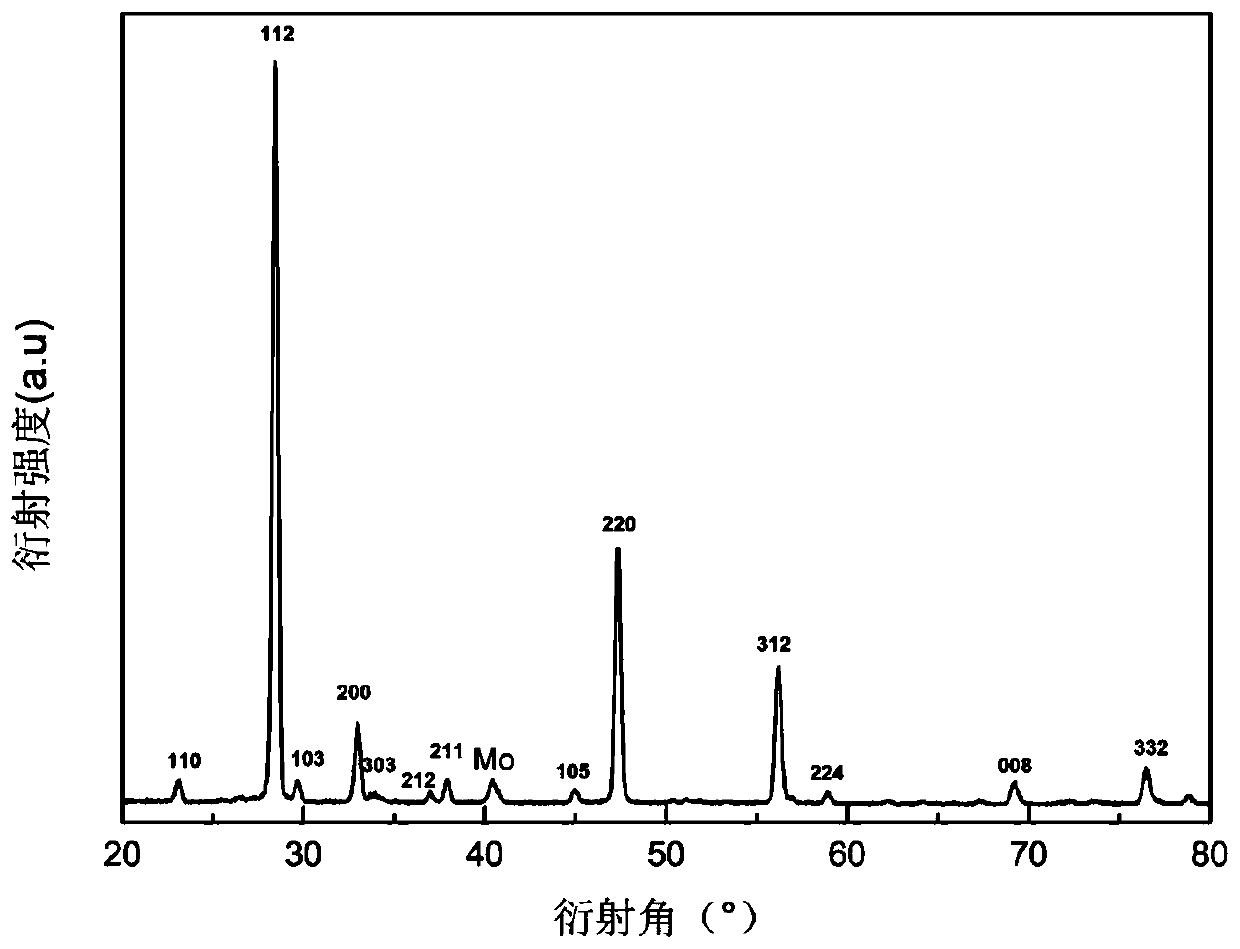

[0051] In summary, image 3 and Figure 7 The X-ray diffraction spectra of the silver-doped copper-zinc-tin-sulfur prepared in Example 1 and Example 2 respectively. Both figures are consistent with the standard diffraction peaks of copper, zinc, tin and sulfur, and the intensity of the diffraction peaks is higher, indicating that the sample has bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com