Electric truck connecting rod auxiliary wheel device

A technology for electric pallet trucks and auxiliary wheels, which is applied in the direction of motor vehicles, transportation, and packaging. It can solve the problems of accelerating auxiliary wheel wear, prolonging driving vibration, and increasing operator fatigue, so as to improve operating comfort, reduce fatigue intensity, The effect of shortening the vibration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

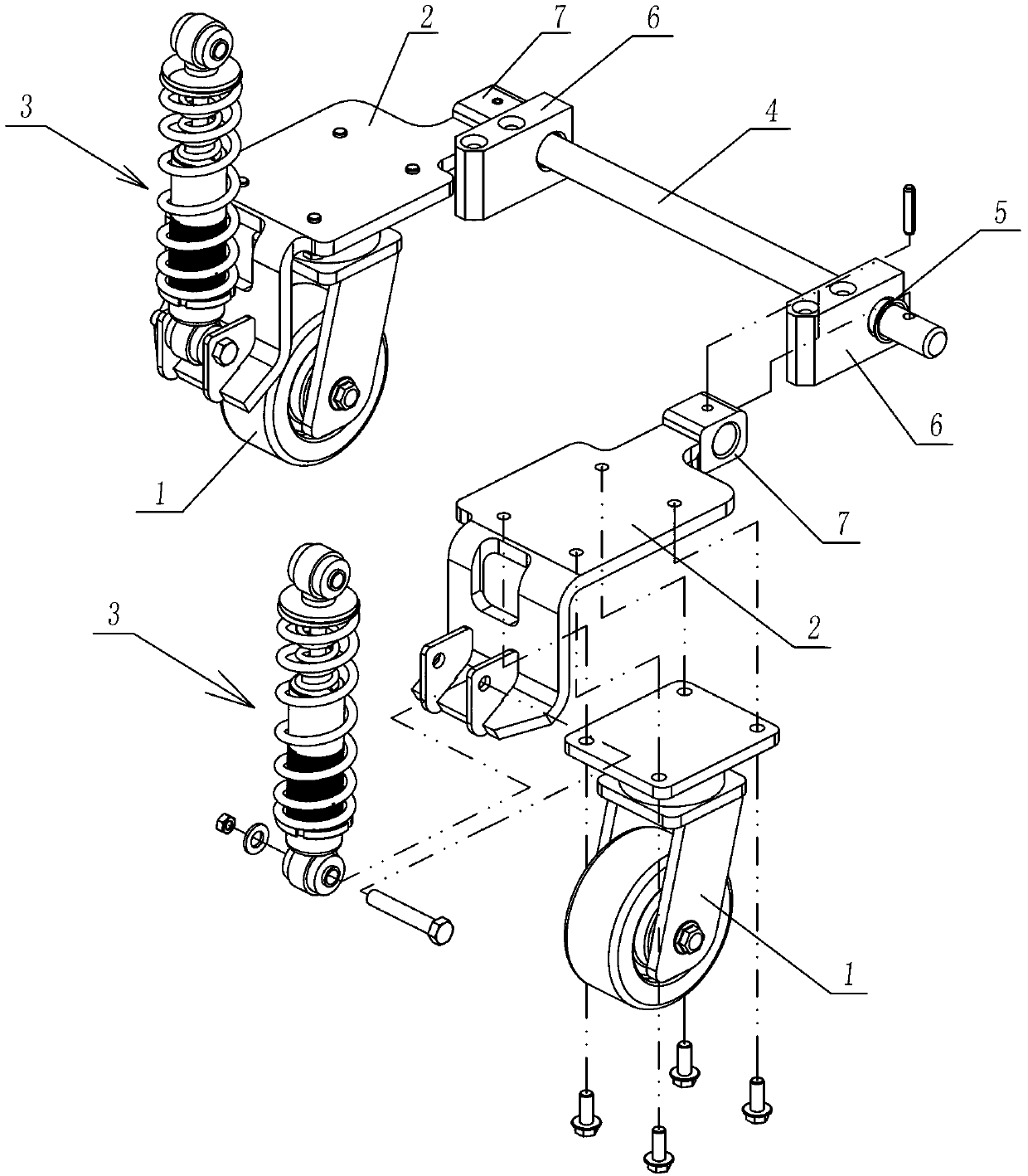

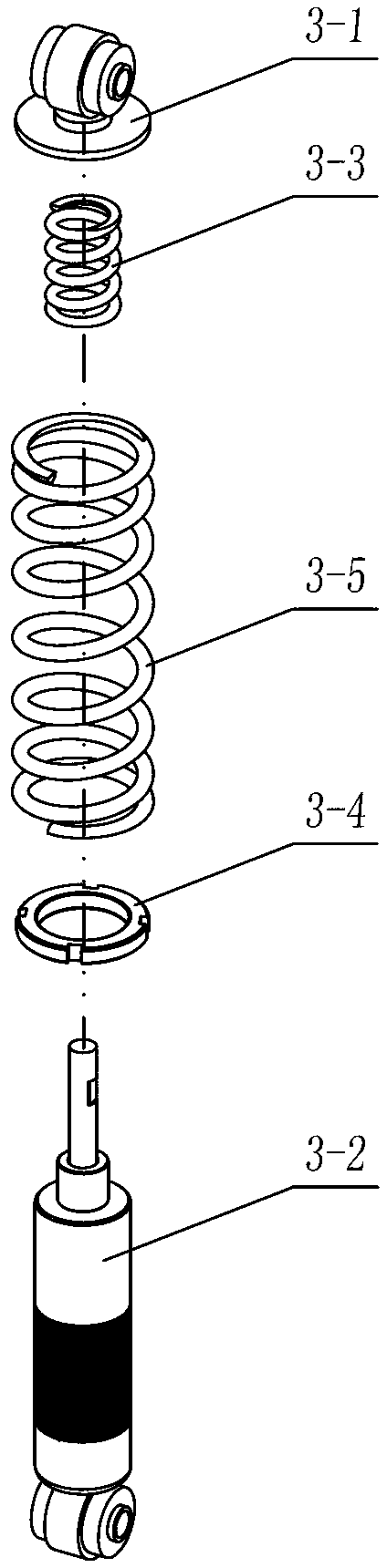

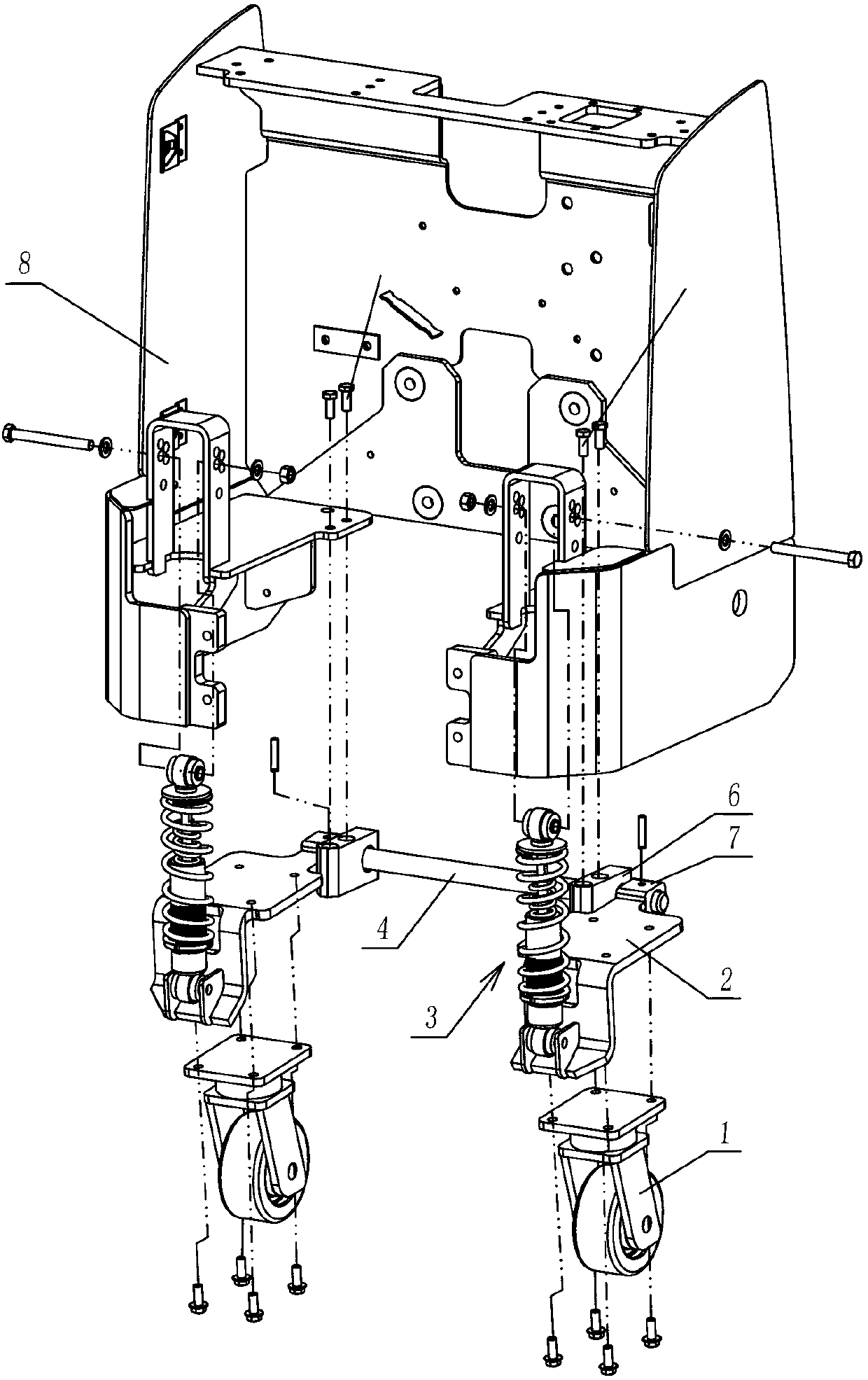

[0013] Such as figure 1 As shown, this embodiment includes an auxiliary wheel 1, a support plate 2 and a shock absorber assembly 3; wherein the auxiliary wheel 1 is installed on the lower surface of the support plate 2, and can freely rotate 360 degrees in the horizontal plane; one end of the support plate 2 is located at the The hinge seat on its upper surface is hinged with one end of the shock absorber assembly 3, and the other end of the shock absorber assembly is hinged with the vehicle frame 8. At the same time, the other end of the support plate 2 is integrally formed with a connector 7 with a through hole. A rotating shaft 4 that can rotate together with the support plate 2 is installed through a pin shaft in the through hole of the connector, and a shaft sleeve 5 is installed on the outside of the rotating shaft to be fixedly connected with the vehicle frame 8 and can rotate freely relative to the rotating shaft 4 . seat 6; after the installation is completed, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com