Disc brake with permanent magnet parking brake mechanism and braking method

A disc brake and brake mechanism technology, applied in the direction of brake actuators, brake types, axial brakes, etc., can solve the problems of high manufacturing cost, power consumption, complex structure, etc., and reduce fatigue strength, quantity and Reasonable location arrangement, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

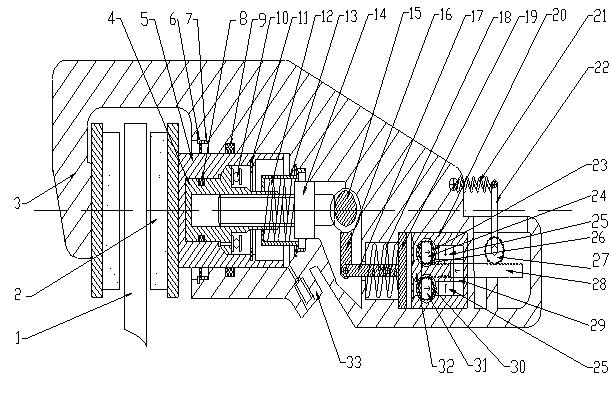

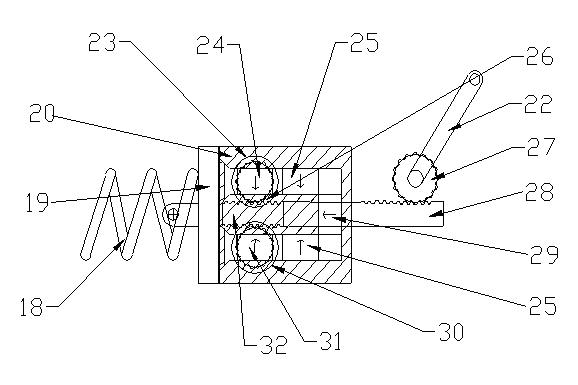

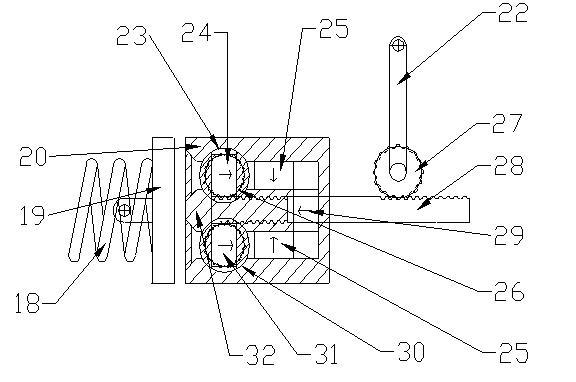

[0017] Such as figure 1 As shown, the disc brake of the present invention includes a cylinder block 3 with a brake block assembly 2 in the cylinder block 3, and a brake disc 1 is arranged at a corresponding position in the brake block assembly 2. In the cylinder 3, a master piston 5 is also provided on the right side of the brake block assembly 2. The master piston 5 is coaxial with the brake disc 1 and can move axially in the direction of the brake disc 1.

[0018] The main piston 5 has a cylindrical structure. A propelling screw sleeve 4 is coaxially sleeved in the cylindrical inner cavity of the main piston 5 and sealed with a sealing ring 8. The left end surface of the pushing screw sleeve 4 is in contact with the inner surface of the main piston 5. A compensation plane bearing 10 is provided between the propulsion screw sleeve 4 and the main piston 5. The right side of the pushing screw sleeve 4 is a circlip 11, and the pushing screw sleeve 4 is positioned inside the main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com