Automobile power assembly suspension device

An automotive powertrain and engine mount technology, applied in power units, control devices, jet propulsion devices, etc., can solve the problems of affecting the ride comfort of cars, poor vibration isolation capability, large vibration and noise, etc., and achieve structural Novel, reduce fatigue strength, reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

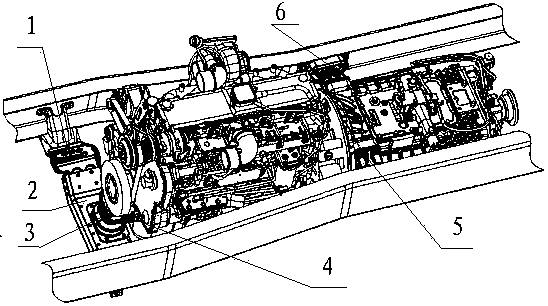

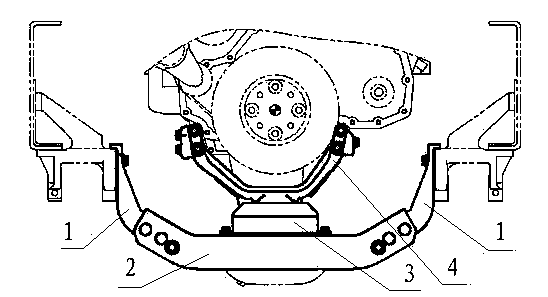

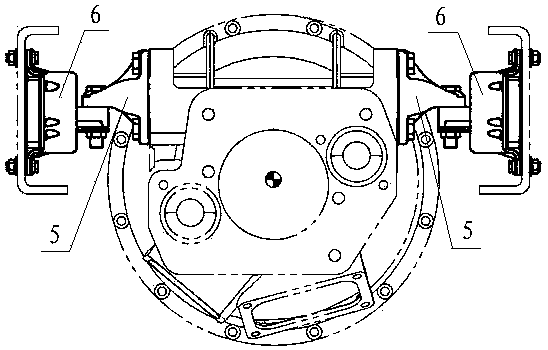

[0014] figure 1 The automotive powertrain mounts include the engine mounts on the front of the engine and the two gearbox mounts on the rear gearbox of the engine, such as figure 2 and image 3 As shown; the engine suspension includes a front suspension cylinder bracket 4 connected to the bottom of the engine, and a front suspension beam 2 with two ends connected to the front suspension bracket 1 is arranged below the front suspension cylinder bracket 4, two front suspension cylinders The suspension bracket 1 is connected with the vehicle beams on both sides; the front suspension cushion 3 is arranged between the front suspension cylinder bracket 4 and the front suspension beam 2; the transmission suspension includes two Rear suspension cylinder support 5, two rear suspension cylinder supports 5 are respectively connected with two rear suspension cushions 6 fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com