Nanocrystalline composite center-based stacked solar cell and preparation method thereof

A nanocrystalline composite, solar cell technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of complex structure and preparation process, lag of laminated devices, complex preparation process, etc., to reduce production costs, system compatibility, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Preparation of stacked solar cells.

[0058] (1) Preparation of the front sub-battery:

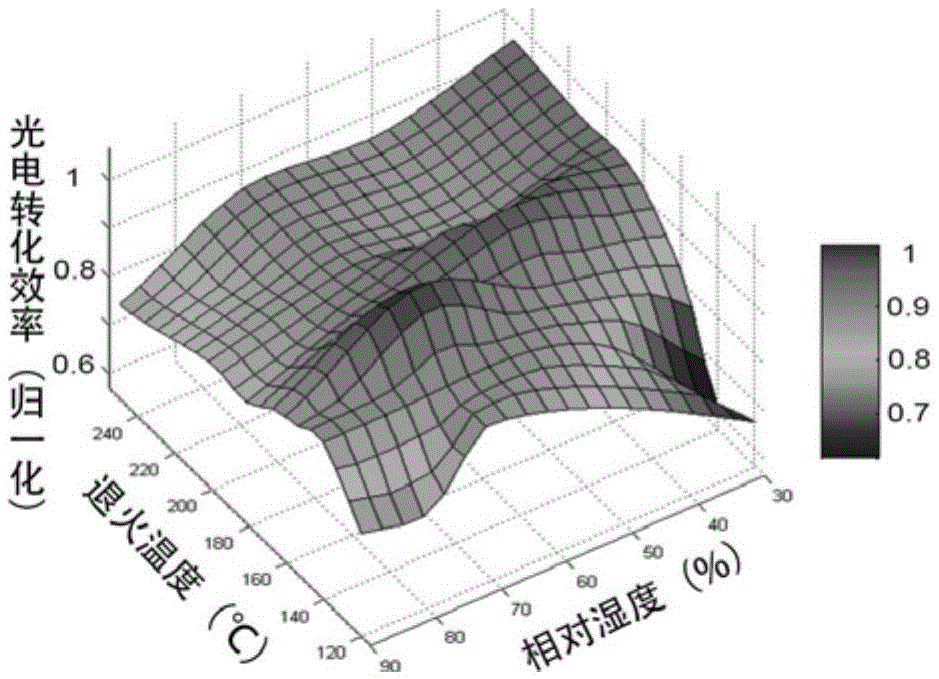

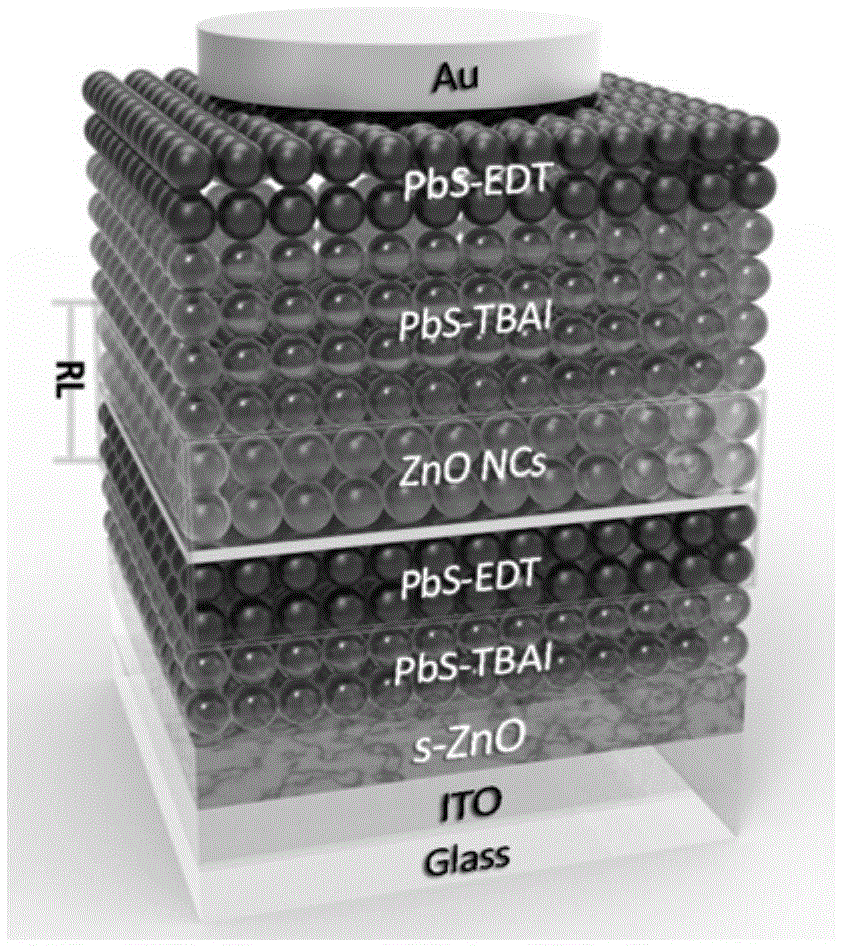

[0059] Use deionized water, isopropanol, and acetone to ultrasonically clean the ITO conductive glass in sequence, and set aside. Weigh zinc acetate dihydrate (220 mg), 2-methoxyethanol (2 mL) and ethanolamine (60 μL), mix and stir for 5 min to obtain a zinc oxide precursor solution, which is then spin-coated on the cleaned surface at a speed of 4000 rpm. On the ITO conductive glass, anneal at 140°C for 10min at 90%RH (according to figure 1 The results shown in the selection of the best humidity (90%RH) and annealing temperature (140 ℃)), to obtain a 50nm thick sol-gel zinc oxide layer (such as figure 2 shown in the s-ZnO layer).

[0060] Reference Chia-Hao M. Chuang, Patrick R. Brown, Moungi G. Bawendi, et.al. , Nat. Mater. , 2014 , 13(8):796-801, the method for preparing lead sulfide quantum dots (particle size is 2~5nm, preferably 2.6nm), the specific process ...

Embodiment 2

[0071] Example 2: Photoelectric performance of tandem solar cells.

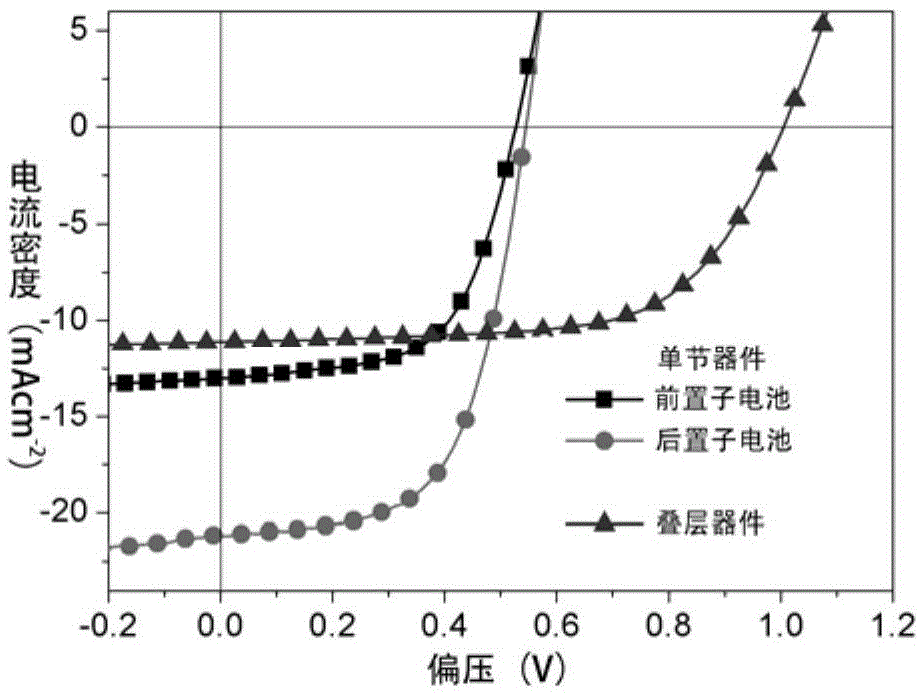

[0072] Under AM1.5 simulated light source (calibrated with NREL-certified standard silicon cells), at 100mW / cm2 The power of the tandem solar cell and the single-junction sub-cell prepared in Example 1 I-V The curves are compared and tested, and the results are as follows image 3 and shown in Table 1.

[0073] It can be seen that the difference between the open circuit voltage Voc of the laminated battery connected through the nanocrystalline recombination center and the sum of the Voc of the front and rear sub-batteries is only 0.01V, which shows its high efficiency as a recombination center. Moreover, the overall photoelectric conversion efficiency of stacked devices is higher than that of single-junction cells, indicating that the stacked device structure is an effective way to improve the photoelectric conversion efficiency of nanocrystalline solar cells.

[0074]

Embodiment 3

[0075] Embodiment 3: Stability test of laminated batteries.

[0076] In order to investigate the stability of laminated batteries, long-term stability tests were carried out on unpackaged devices, and the results were as follows: Figure 4 shown.

[0077] from Figure 4 It can be seen that the tandem cell based on the PbS-EDT / Au / ZnO composite center in the present invention basically maintained the initial photoelectric conversion efficiency during the test period of up to 60 days, while the PEDOT used in the traditional solvent method / ZnO recombination center devices have experienced a sudden drop in photoelectric conversion efficiency within a test period of about 15 days. It can be seen that the tandem solar cell based on the nanocrystalline recombination center in the present invention has excellent air stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com