Bipolar plate of fuel cell and method for preparing carbon titanium nanocomposite film on surface thereof

A fuel cell and nanocomposite technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to meet the high voltage requirements of electrolytic cells, inability to meet the requirements of voltage fluctuation operation, and high preparation costs, and achieve binding force. Strong, reduced contact resistance, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

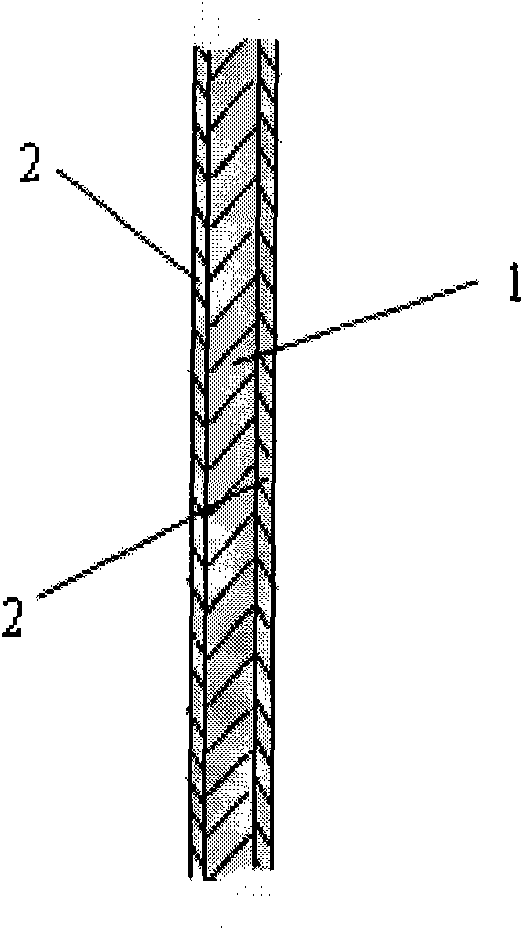

Embodiment 1

[0026]Put the stainless steel thin plate bipolar plate base material into the vacuum chamber of the arc ion plating equipment after pretreatment such as cleaning and drying, install the graphite target and the pure titanium target at intervals on the position of the cathode arc source, and vacuumize to 5×10- 3Pa, pass the argon gas to 1Pa, start the titanium target arc to obtain the arc plasma, the arc current is 50A, add the pulse bias voltage of -1000V×20kHz×60%, and at the same time trigger the glow plasma of argon gas, use the argon in the plasma Ions and titanium ions are used to remove the passivation film by ion sputtering on the bipolar plate for 10 minutes, reduce the bias voltage amplitude to -300V, adjust the titanium target arc flow to 80A and the graphite target arc flow to 40A, and start depositing carbon-titanium film. The time is 40 minutes. After the time is up, the post-processing of unloading the bias voltage, stopping the arc, stopping the gas, and keeping t...

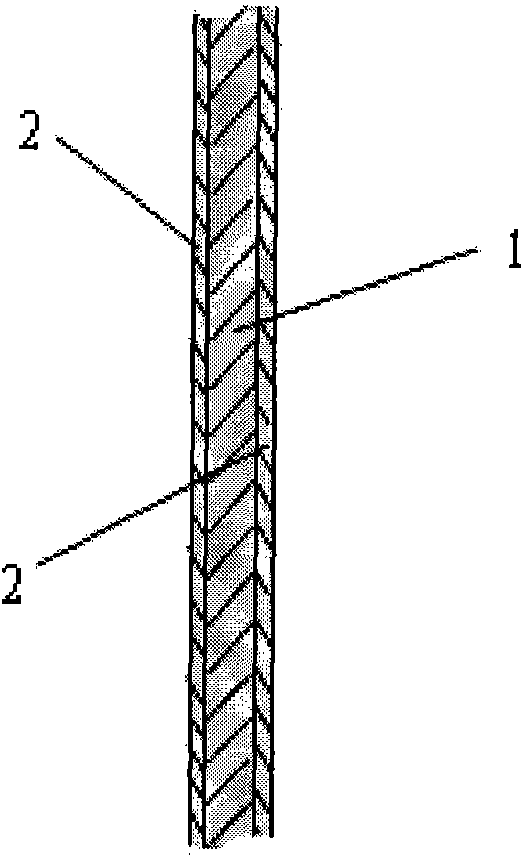

Embodiment 2

[0028] Put the titanium thin plate bipolar plate base material into the vacuum chamber of the arc ion plating equipment after pretreatment such as cleaning and drying, install graphite targets and pure titanium targets at intervals on the position of the cathode arc source, and vacuumize to 5×10- 3Pa, pass argon gas to 1Pa, start the titanium target arc to obtain arc plasma, each titanium target arc current is 50A, add -800V×20kHz×60% pulse bias and simultaneously trigger the glow plasma of argon gas, use plasma The argon ions and titanium ions in the body perform ion sputtering on the bipolar plate to remove the passivation film for 10 minutes, reduce the bias voltage amplitude to -300V, change the argon partial pressure to 0.5Pa, stop the titanium arc, start the graphite arc, Adjust the flow of each graphite arc at 40A, start to deposit the first layer of carbon layer, then start the titanium arc after 60S, deposit the second layer of carbon-titanium layer, stop the titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com