Rapid preparation of high performance nanostructured filling type skutterudite thermoelectric material

A technology of nanostructured and thermoelectric materials, applied in the field of preparation of thermoelectric compounds, can solve the problems of high energy consumption, unsatisfactory thermoelectric performance, no major breakthroughs, etc., to save annealing time, reduce preparation cost, and shorten reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

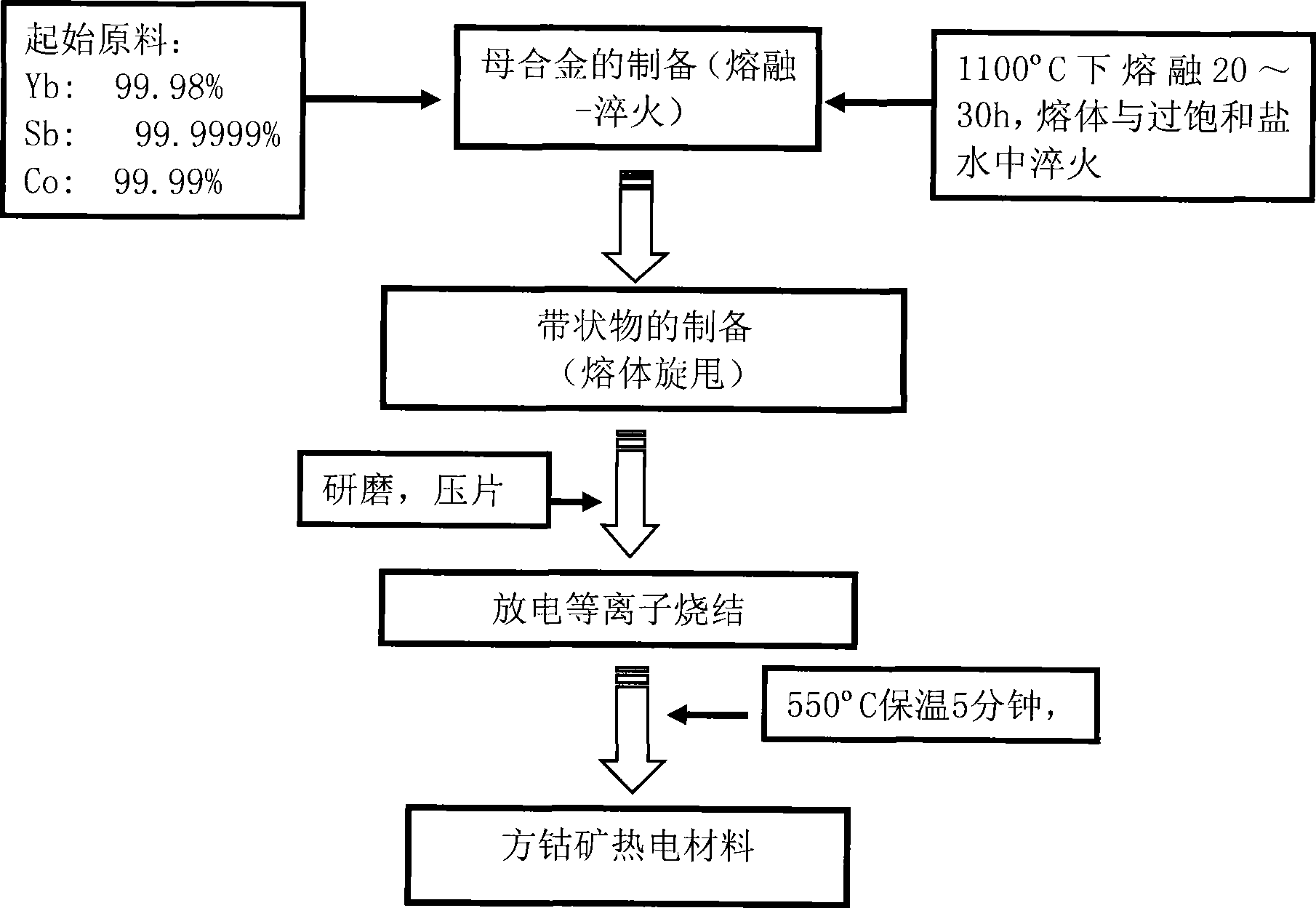

[0023] Such as figure 1 Shown, the rapid preparation method of high-performance nanostructure filled skutterudite thermoelectric material, it comprises the following steps:

[0024] 1) Ingredients: Using granular Yb, granular Co and granular Sb as starting materials, the reaction raw materials are formulated according to the chemical formula Yb 0.3 co 4 Sb 12.3 Weigh; Wherein, the purity of granular Yb is 99.98% (mass), the purity of granular Co is 99.99% (mass), and the purity of granular Sb is 99.9999% (mass);

[0025] 2) Preparation of master alloy: Mix granular Yb, granular Co and granular Sb, then put them into a melting furnace, slowly heat to 1100°C at a heating rate of 2°C / min, and melt for 20 to 30 hours (in this range All have the ability to realize the present invention, such as 20h or 30h), to obtain a melt; the melt is quenched in supersaturated brine to obtain a master alloy (ingot with dense metallic luster);

[0026] 3) Preparation of strip-shaped products:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com