Method for preparing amorphous/nanometer crystal multilayer-structure film

A multi-layer structure and nanocrystalline layer technology, which is applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem of test sample fracture, etc., and achieve low cost, clear structure, easy to realize and popularize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

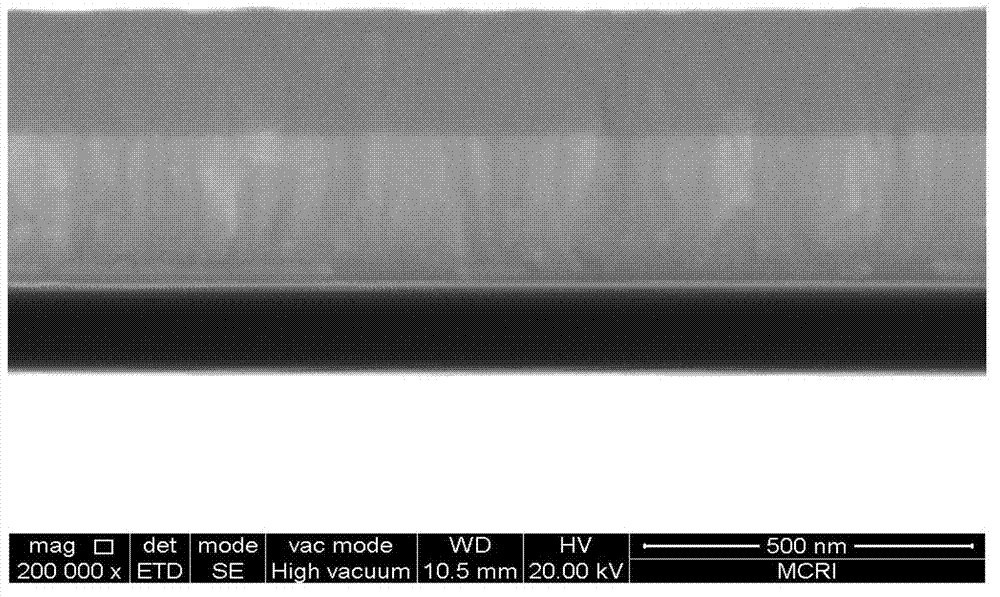

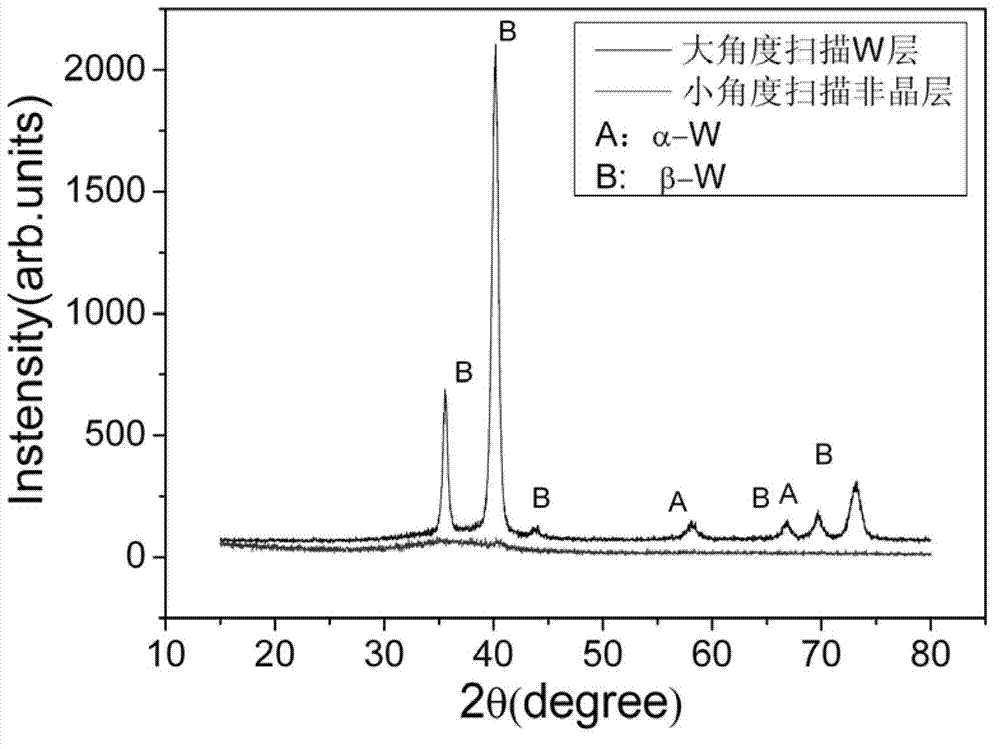

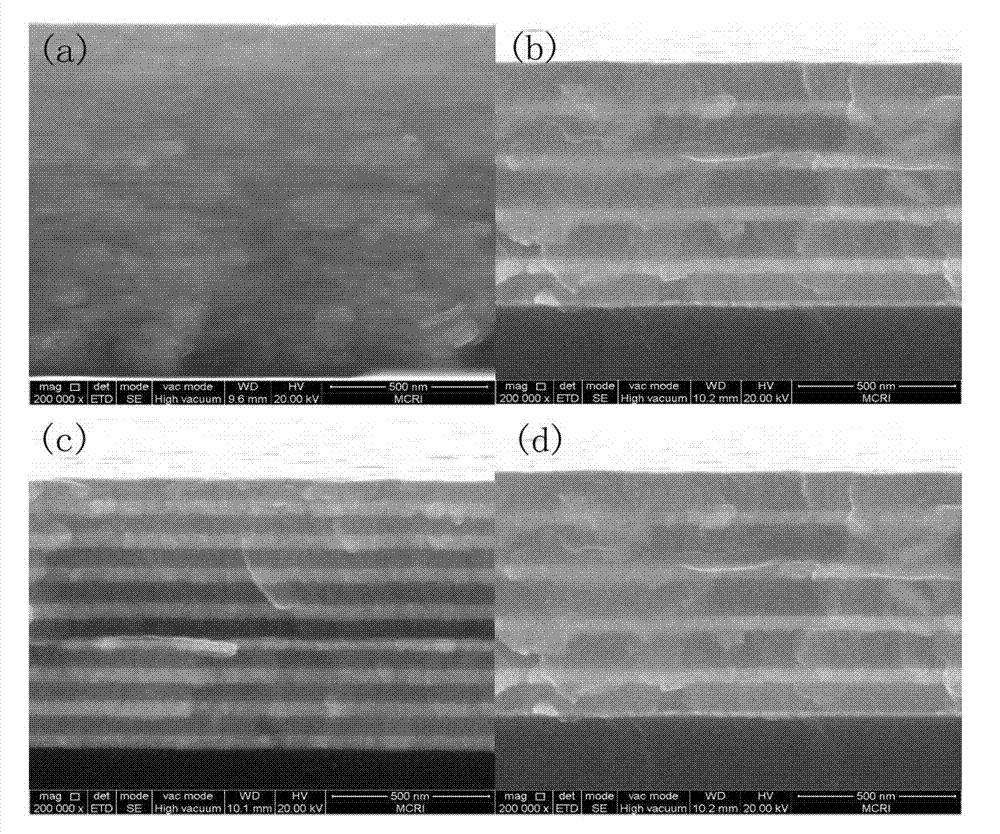

[0021] The main principle of the method adopted in the present invention is: in the magnetron sputtering coating process, the intermittent deposition process is adopted to keep the film growth at a lower temperature all the time, effectively protecting various film structures from being damaged (if continuous deposition Coating, it is easy to cause the temperature of the film to rise so that the structure of the amorphous layer is destroyed, and the grains of the nanocrystalline layer are coarse), through a specific element ratio, a negative mixing heat can be formed between sputtering atoms, and magnetron sputtering This unbalanced atomic deposition method can effectively obtain amorphous thin films. In addition, by controlling the different settings of a series of experimental parameters such as rotation speed, bias voltage, and power during the sputtering process, it is possible to realize the alternate alternation of the amorphous layer film and the nanocrystalline layer fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com