Preparation method of diamond composite coating of micro milling cutter

A composite coating, diamond technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, to achieve the effect of delaying cracks, reducing processing costs, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

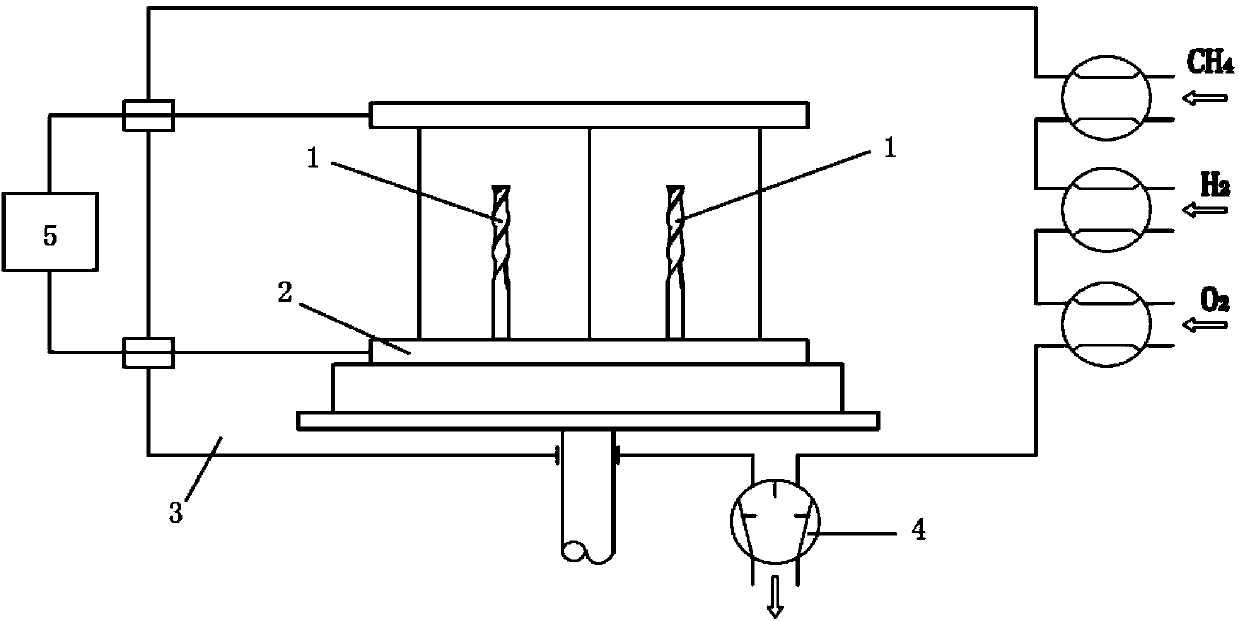

[0029] see figure 1 , using diamond coating equipment for production, the preparation includes the following steps:

[0030] Step a. Load the PCB micro milling cutter 1 into the tooling 2;

[0031] Step b. Install the tooling 2 equipped with the micro milling cutter 1 into the deposition reaction chamber 3;

[0032] Step c. The deposition reaction chamber 3 is evacuated to a vacuum state with a vacuum pump 4;

[0033] step d. Methane (CH 4 ), hydrogen (H 2 ) and oxygen (O 2 ) 3 kinds of gases; among them, the volume ratio of methane, hydrogen and oxygen is (0.1%~10%): (90%~99.99%): (0%~5%);

[0034] Step e. A direct current arc is passed from the power supply 5 to the heating wire installed in the deposition reaction chamber 3; wherein, the heating wire is a tungsten wire or a tantalum wire; the temperature of the heating wire is 2000-2100°C; the applied arc current is 180A;

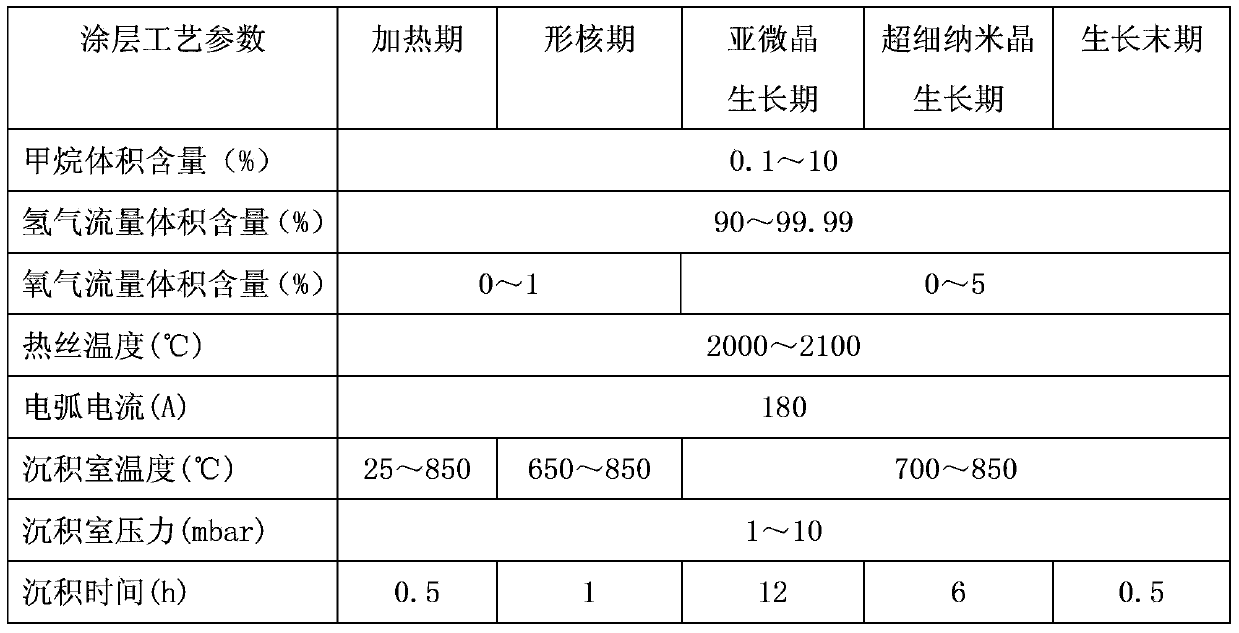

[0035] step f. In the deposition reaction chamber 3, the deposition process is divided in...

Embodiment 2

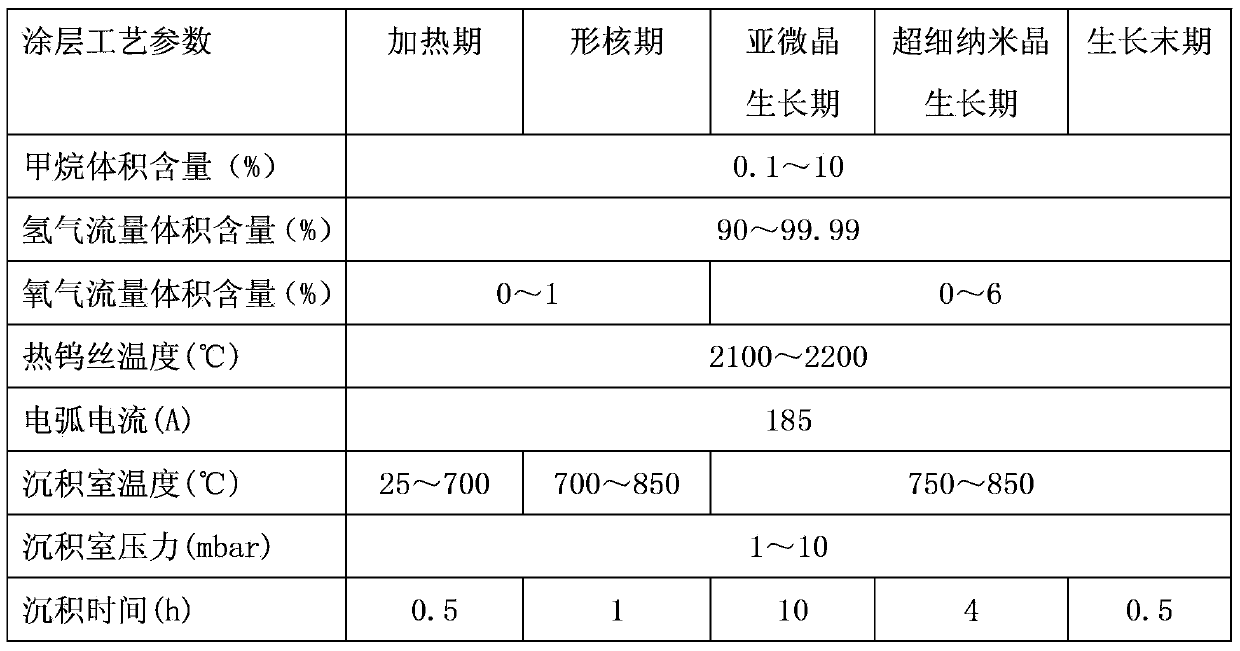

[0040] The preparation method of the diamond composite coating of a kind of PCB micro milling cutter of the present invention is similar to embodiment 1, and its difference is:

[0041] step d. Methane CH is introduced into the deposition reaction chamber 4 , hydrogen H 2 and oxygen O 2 Three kinds of gases; among them, the volume ratio of methane, hydrogen and oxygen is (0.1%~10%): (90%~99.99%): (0~6%);

[0042] Step e. Introduce a DC arc to the tungsten wire installed in the deposition reaction chamber; where the temperature of the heating wire is 2100-2200 ° C; the applied arc current is 185A;

[0043] step f. In the deposition reaction chamber, the deposition process is divided into five stages: heating period, nucleation period, submicrocrystalline growth period, ultrafine nanocrystal growth period, and end-of-growth period. The five stages adopt different vapor deposition conditions. The phase and ultrafine nanocrystal growth period can occur cyclically, and the nu...

Embodiment 3

[0048] The preparation method of the diamond composite coating of a kind of PCB micro milling cutter of the present invention is similar to embodiment 1, and its difference is:

[0049] step d. Methane CH is introduced into the deposition reaction chamber 4 , hydrogen H 2 and oxygen O 2 Three kinds of gases; among them, the volume ratio of methane, hydrogen and oxygen is (0.1%~10%): (90%~99.99%): (0~7%);

[0050] Step e. Introduce a direct current arc to the tungsten wire installed in the deposition reaction chamber; among them, the temperature of the heating tungsten wire is 2300°C; the applied arc current is 190A;

[0051] step f. In the deposition reaction chamber, the deposition process is divided into five stages: heating period, nucleation period, submicrocrystalline growth period, ultrafine nanocrystal growth period, and end-growth period. The five stages adopt different atmospheric deposition conditions, and the submicrocrystalline growth The phase and ultrafine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com