Thermal interface material and its production

A technology of thermal interface materials and nanocomposite materials, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor thermal conductivity of thermal interface materials, insufficient thermal conductivity, and inability to meet the needs of heat dissipation performance, etc. Excellent thermal conductivity, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

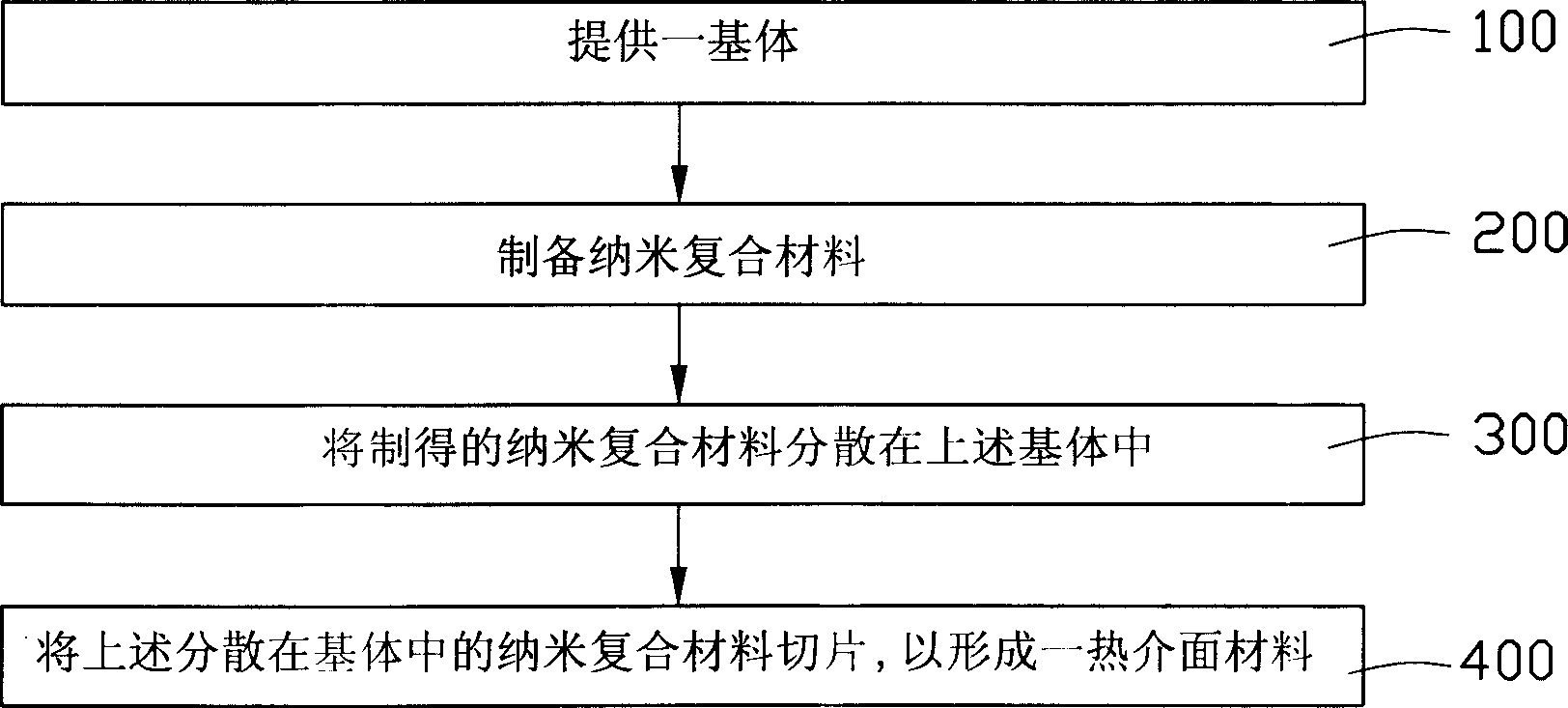

[0028] The present embodiment will be further described in detail below in conjunction with the accompanying drawings.

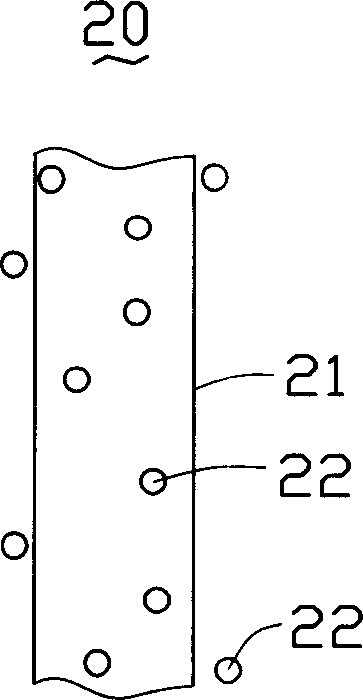

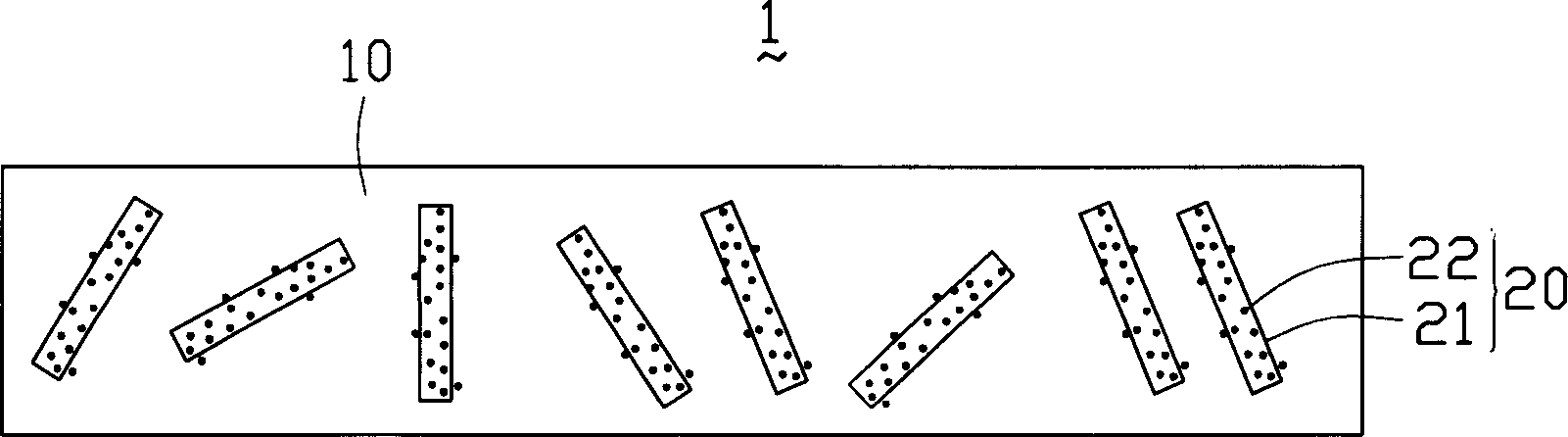

[0029] See figure 1 and figure 2 , figure 1 is a schematic structural view of the nanocomposite material 20 in this embodiment, figure 2 It is a schematic diagram of the composition of the thermal interface material 1 in this embodiment. The first embodiment of the present invention provides a thermal interface material 1 , which includes a matrix 10 and nanocomposite materials 20 distributed in the matrix 10 . Wherein, the nanocomposite material 20 includes nanofibers 21 and heat conducting particles 22 distributed inside and outside the nanofibers 21 .

[0030] The material of the substrate 10 can be selected from polymer materials such as silica gel, polysiloxane resin, epoxy resin, polyester, polyester oil, polyurethane, polyimide or polyacrylic acid. The nanofibers 21 can be selected from fiber materials such as carbon nanotubes, carbon nanowires...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com