Acetylated cellulose nanocrystalline composite modified biomass-based polyester material and preparation method thereof

A biomass-based polyester and nanocrystalline composite technology, applied in the field of natural polymer materials, can solve the problems of high brittleness and limit the application range of polyhydroxybutyrate, and achieve reduced toughness, increased rigidity, and improved Young's modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

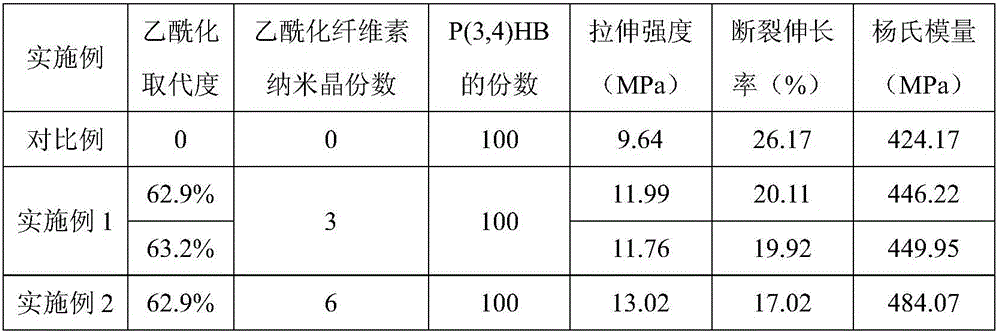

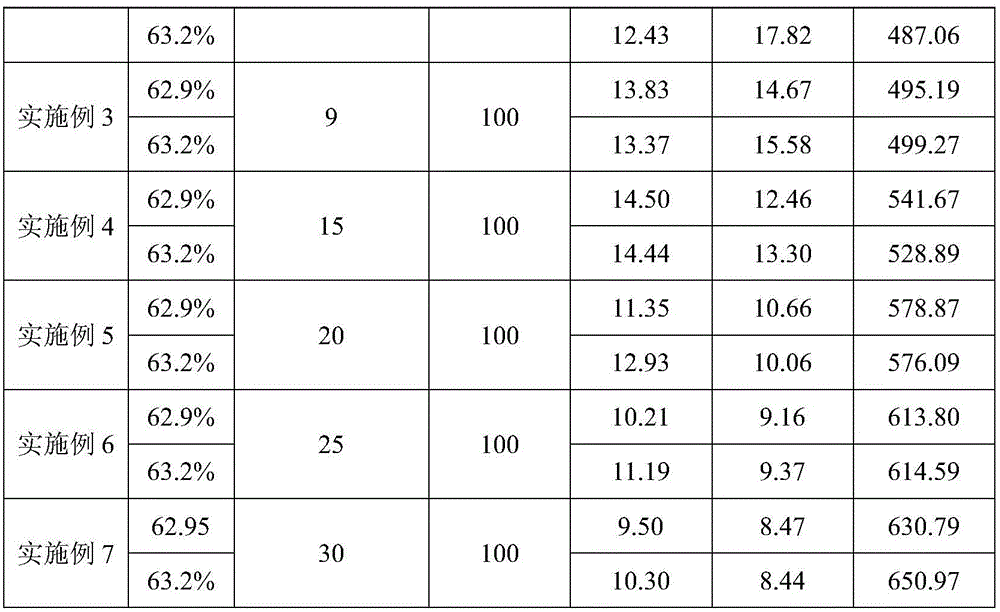

Embodiment 1

[0023] A kind of acetylated cellulose nanocrystalline composite modified biomass-based polyester material, prepared by the following method:

[0024] (1) According to 3 parts of acetylated cellulose nanocrystals (the degree of acetylation substitution is 62.9% and 63.2%, respectively), 100 parts of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), select acetylated Cellulose nanocrystals, poly(3-hydroxybutyrate-co-4-hydroxybutyrate), acetylated cellulose nanocrystals are dispersed in chloroform, after ultrasonic treatment (ultrasonic times 3 times, ultrasonic time 10min / time) to obtain acetylated cellulose nanocrystal suspension;

[0025] (2) Add poly(3-hydroxybutyrate-co-4-hydroxybutyrate) to the suspension of acetylated cellulose nanocrystals, and continue magnetic stirring until poly(3-hydroxybutyrate-co- 4-hydroxybutyrate) obtains the homogeneous blend after dissolving completely;

[0026] (3) Pour the homogeneously mixed blend into a polytetrafluoroethylene mold, keep it at...

Embodiment 2

[0029] A kind of acetylated cellulose nanocrystalline composite modified biomass-based polyester material, prepared by the following method:

[0030] (1) According to 6 parts of acetylated cellulose nanocrystals (the degree of acetylation substitution is 62.9% and 63.2%, respectively), 100 parts of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), select acetylated Cellulose nanocrystals, poly(3-hydroxybutyrate-co-4-hydroxybutyrate), acetylated cellulose nanocrystals are dispersed in chloroform, after ultrasonic treatment (ultrasonic times 3 times, ultrasonic time 10min / time) to obtain acetylated cellulose nanocrystal suspension;

[0031] (2) Add poly(3-hydroxybutyrate-co-4-hydroxybutyrate) to the suspension of acetylated cellulose nanocrystals, and continue magnetic stirring until poly(3-hydroxybutyrate-co- 4-hydroxybutyrate) obtains the homogeneous blend after dissolving completely;

[0032] (3) Pour the homogeneously mixed blend into a polytetrafluoroethylene mold, keep it at...

Embodiment 3

[0035] A kind of acetylated cellulose nanocrystalline composite modified biomass-based polyester material, prepared by the following method:

[0036] (1) According to 9 parts of acetylated cellulose nanocrystals (the degree of acetylation substitution is 62.9% and 63.2%, respectively), 100 parts of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), select acetylated Cellulose nanocrystals, poly(3-hydroxybutyrate-co-4-hydroxybutyrate), acetylated cellulose nanocrystals are dispersed in chloroform, after ultrasonic treatment (ultrasonic times 3 times, ultrasonic time 10min / time) to obtain acetylated cellulose nanocrystal suspension;

[0037] (2) Add poly(3-hydroxybutyrate-co-4-hydroxybutyrate) to the suspension of acetylated cellulose nanocrystals, and continue magnetic stirring until poly(3-hydroxybutyrate-co- 4-hydroxybutyrate) obtains the homogeneous blend after dissolving completely;

[0038] (3) Pour the homogeneously mixed blend into a polytetrafluoroethylene mold, keep it at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com