ZnO/Cu nanometer crystal composite material, and preparation method and application thereof

A technology of composite materials and nanocrystals, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as large particle size, difficult synthesis of nanocrystalline materials, and insufficient high-temperature stability. Achieve the effect of good catalytic performance and high catalytic performance promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the above-mentioned ZnO / Cu nanocrystalline composite material, comprising the following steps:

[0037] A) Provide Cu 2 O nanocrystals, the Cu 2 O nanocrystals are cubes or octahedrons;

[0038]B) Using zinc nitrate as a precursor, uniformly distribute zinc nitrate on Cu by equal volume impregnation 2 O nanocrystalline surface, calcined under inert atmosphere to obtain ZnO / Cu 2 O nanocrystalline composite material;

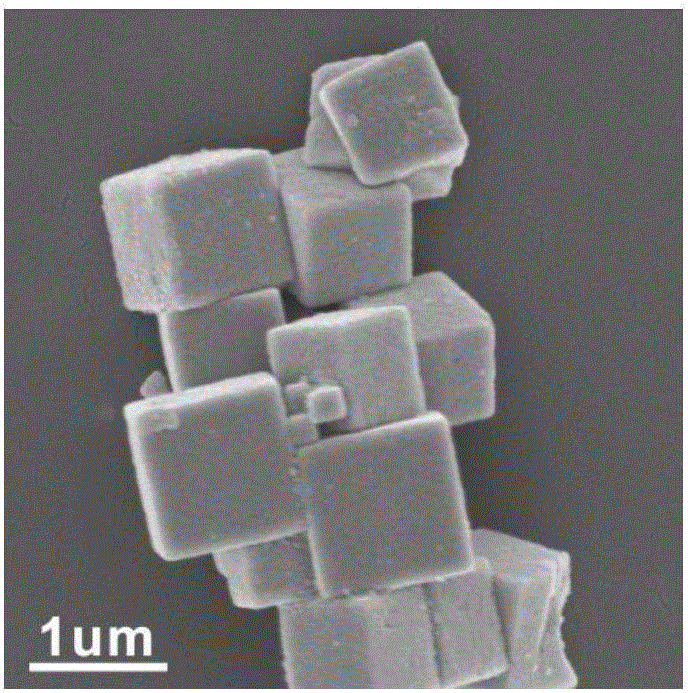

[0039] C) ZnO / Cu 2 O nanocrystalline composite material is calcined under reducing atmosphere, obtains ZnO / Cu nanocrystalline composite material; The morphology of described ZnO / Cu nanocrystalline composite material is the same as Cu 2 O nanocrystals are consistent.

[0040] The present invention uses cubic or octahedral Cu 2 O nanocrystals as raw materials.

[0041] The above cubic Cu 2 O nanocrystal is preferably prepared according to the following method as raw material:

[0042] CuCl ...

Embodiment 1

[0076] Cubic Cu 2 Synthesis of O nanocrystals

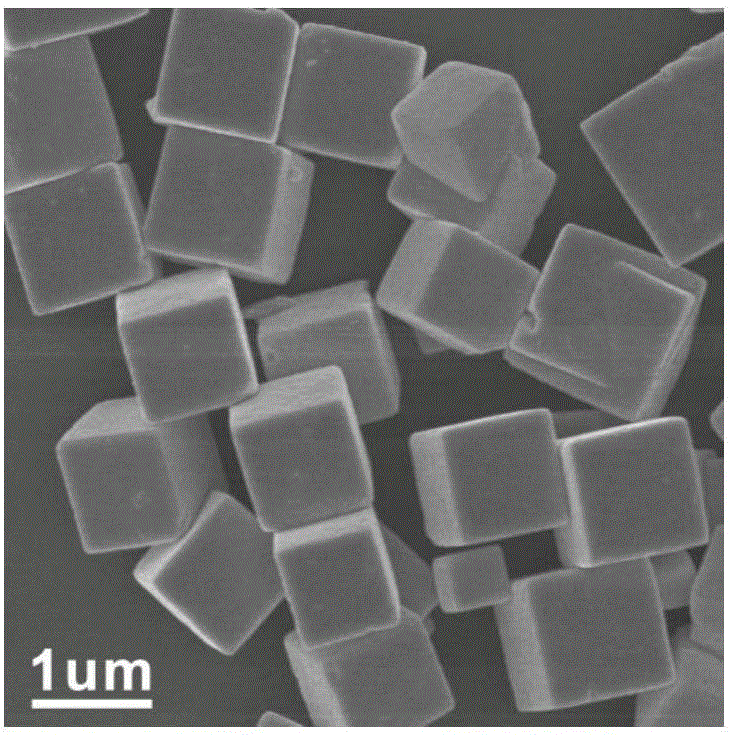

[0077]Use a 250ml three-neck flask to take 100ml of 0.01mol / l CuCl 2 Put the aqueous solution in an oil bath, keep the temperature in an oil bath at 55°C for 30 minutes, then add 10ml of 2mol / l NaOH solution and 10ml of 0.6mol / l ascorbic acid solution in sequence, and react for 5h. Finally, centrifugal washing, vacuum drying for 12h, and then cube Cu 2 O nanocrystals.

[0078] To examine its shape, see figure 1 , figure 1 is cubic Cu 2 SEM images of O nanocrystals.

Embodiment 2

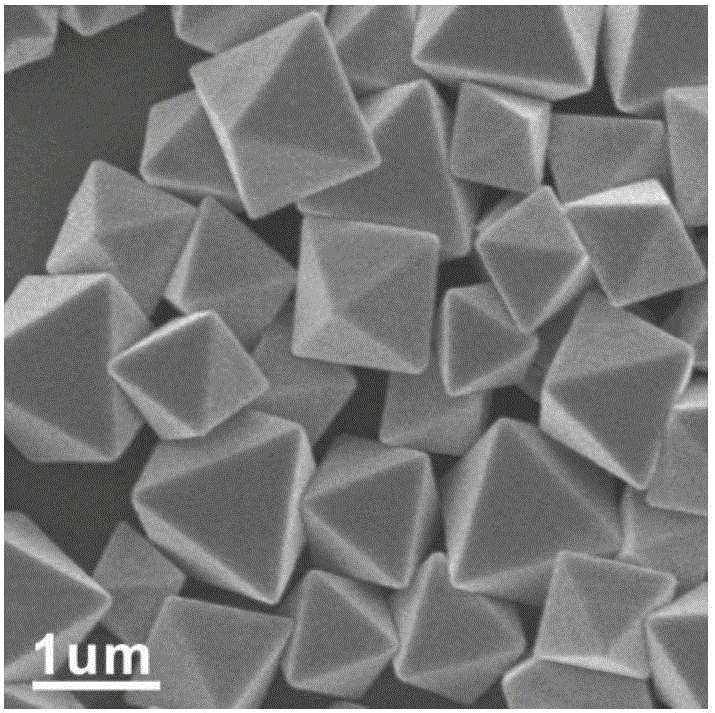

[0080] Octahedral Cu 2 Synthesis of O nanocrystals

[0081] Use a 250ml three-neck flask to take 100ml of 0.01mol / l CuCl 2 The aqueous solution is placed in the oil bath, then add 4.44g PVP (M w =30000), keep the temperature in an oil bath at 55°C for 30min, then add 10ml of 2mol / l NaOH solution and 10ml of 0.6mol / l ascorbic acid solution successively, and react for 3h. Finally, centrifuge washing and vacuum drying for 12 hours, and then the octahedral Cu with PVP protective agent on the surface was obtained. 2 O nanocrystals. After that, take 150mg of octahedral Cu with PVP protectant on the surface 2 O samples were placed in a tube furnace with a fixed ratio of C 3 h 6 / O 2 / Ar mixed gas passes through the sample at a flow rate of 20ml / min, and the temperature rise rate is 5°C / min from room temperature to 200°C, then the temperature is kept at a constant temperature for 30 minutes, and then naturally lowered to room temperature, and then octahedral Cu with a clean sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com