Preparation method of nitrogen-sulfur-phosphorus doped porous graphene oxide material and application of nitrogen-sulfur-phosphorus doped porous graphene oxide material

A technology of element doping and graphene, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve problems such as no literature reports, and achieve the effect of improving graphene performance, high specific capacitance, and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

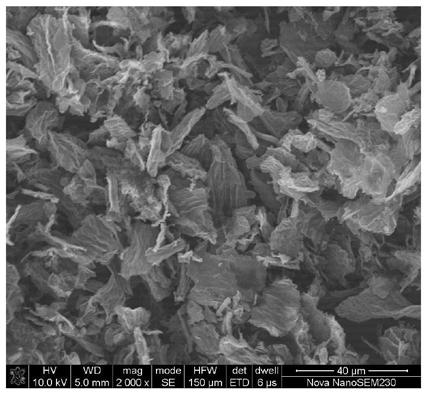

[0041] S1. Weigh the raw material graphene oxide and ultrasonically disperse it in deionized water. The concentration of the obtained graphene oxide dispersion is 0.5 mg / mL, then add 30wt% hydrogen peroxide as a pore-forming agent under strong stirring, and add the volume of hydrogen peroxide and graphite oxide The volume ratio of the olefin dispersion is 1:5, and then the mixed solution is transferred to a hydrothermal reactor, and the reaction is continuously stirred. The reaction temperature is 100° C., and the reaction time is 2 hours. After the reaction, cool to room temperature.

[0042] S2. Centrifuge the product after the reaction obtained in the above step S1, wash with deionized water, and freeze-dry to obtain three-dimensional porous graphene oxide, and ultrasonically disperse the obtained three-dimensional porous graphene oxide solid powder sample into deionized water again, and then Add dopant L-cysteine, ammonium dihydrogen phosphate under strong stirring, the mas...

Embodiment 2

[0047] S1. Weigh the raw material graphene oxide and ultrasonically disperse it in deionized water. The concentration of the obtained graphene oxide dispersion is 2 mg / mL, and then add 30wt% hydrogen peroxide as a pore-forming agent under strong stirring. The volume ratio of the olefin dispersion is 1:5, and then the mixed solution is transferred to a hydrothermal reactor, and the reaction is continuously stirred. The reaction temperature is 100° C., and the reaction time is 2 hours. After the reaction, cool to room temperature.

[0048] S2. Centrifuge the product after the reaction obtained in the above step S1, wash with deionized water, and freeze-dry to obtain three-dimensional porous graphene oxide, and ultrasonically disperse the obtained three-dimensional porous graphene oxide solid powder sample into deionized water again, and then Add dopant L-cysteine, ammonium dihydrogen phosphate under strong stirring, the mass ratio of porous graphene oxide, L-cysteine, and ammoniu...

Embodiment 3

[0053] S1. Weigh the raw material graphene oxide and ultrasonically disperse it in deionized water. The concentration of the obtained graphene oxide dispersion is 0.5 mg / mL, then add 30wt% hydrogen peroxide as a pore-forming agent under strong stirring, and add the volume of hydrogen peroxide and graphite oxide The volume ratio of the olefin dispersion is 1:5, and then the mixed solution is transferred to a hydrothermal reactor, and the reaction is continuously stirred. The reaction temperature is 100° C., and the reaction time is 2 hours. After the reaction, cool to room temperature.

[0054] S2. Centrifuge the product after the reaction obtained in the above step S1, wash with deionized water, freeze-dry to obtain three-dimensional porous graphene oxide, and ultrasonically disperse the obtained three-dimensional porous graphene oxide solid powder sample into deionized water again, and then Add dopant L-cysteine, ammonium dihydrogen phosphate under strong stirring, the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com