Preparation method for visible-light-responsive composite photocatalyst

A composite light and responsive technology, applied in chemical instruments and methods, physical/chemical process catalysts, general water supply conservation, etc., can solve the problems that affect wide application, visible light does not respond, etc., and achieve the effect of cheap reagents and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

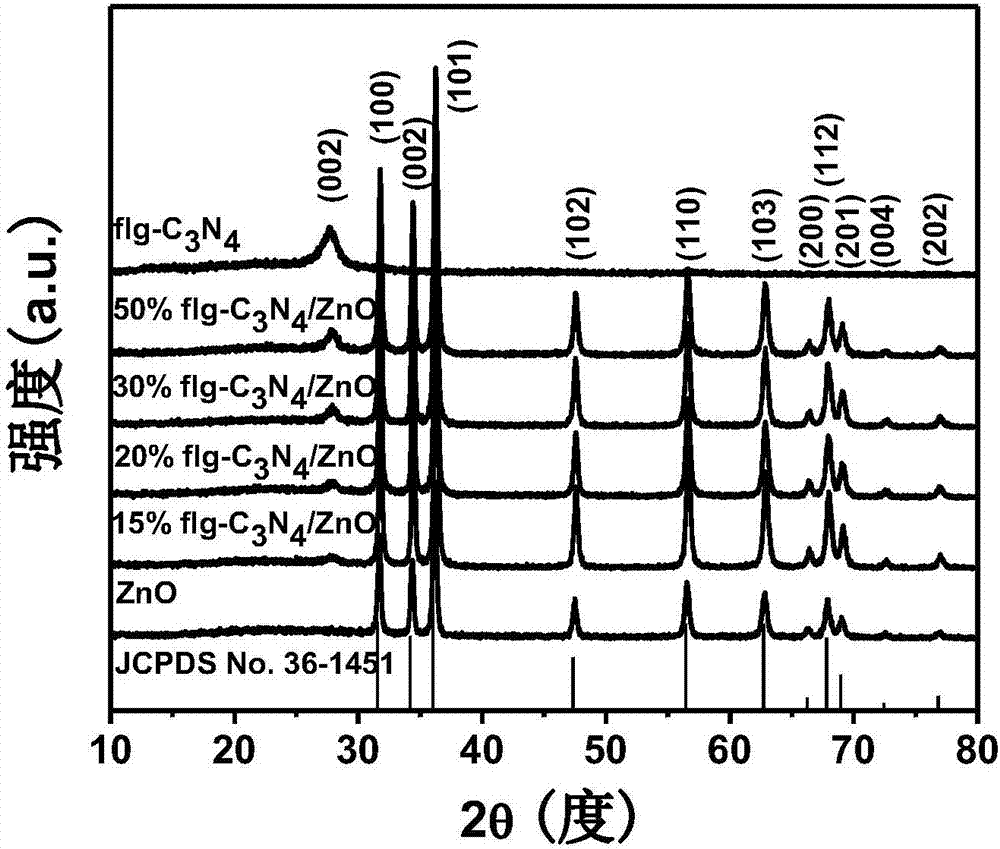

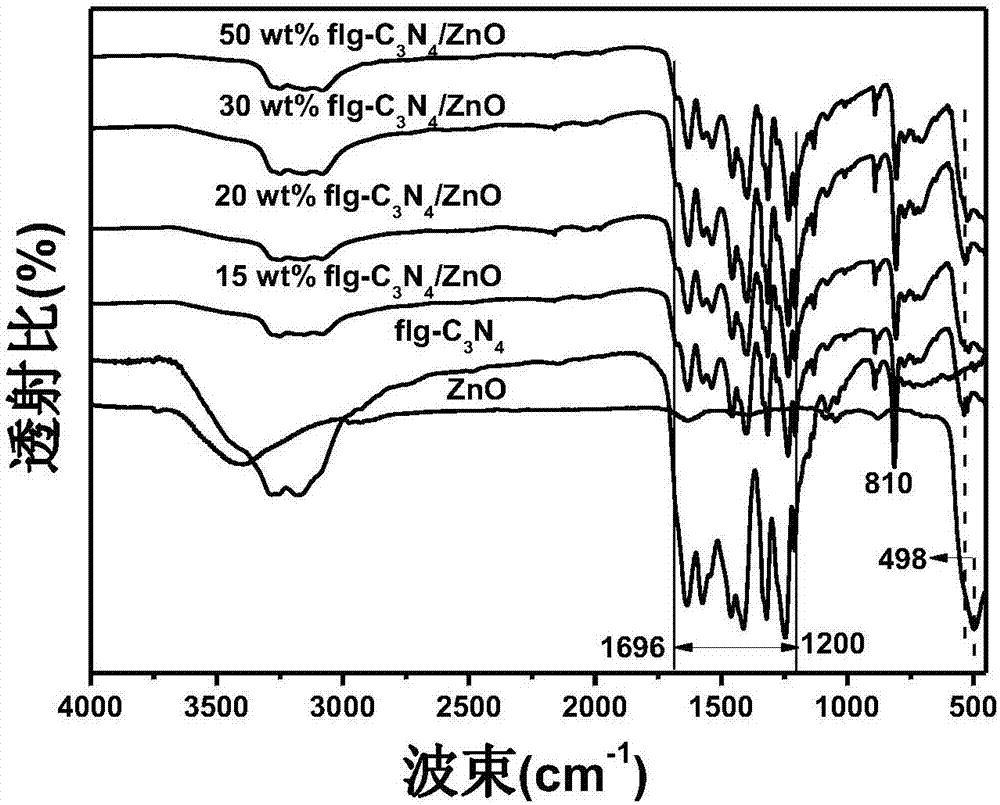

[0025] Embodiment 1: The present invention is a preparation method of a visible light-responsive photocatalyst, comprising the following steps:

[0026] (1) Put melamine in a muffle furnace, raise the temperature to 550°C at a rate of 2°C / min, and keep it for 4 hours to obtain block graphite type C 3 N 4 .

[0027] (2) The block graphite type C 3 N 4 Thermal exfoliation yields few layers of C 3 N 4 , that is, heating at 550°C for 100min with a heating rate of 2°C / min.

[0028] (3) Zn(NO 3 ) 2 Put it in a beaker, add deionized water for ultrasonic dispersion, and after it is completely dissolved, add a certain amount of ammonia water, the volume ratio of ammonia water to deionized water is 2.5:20.

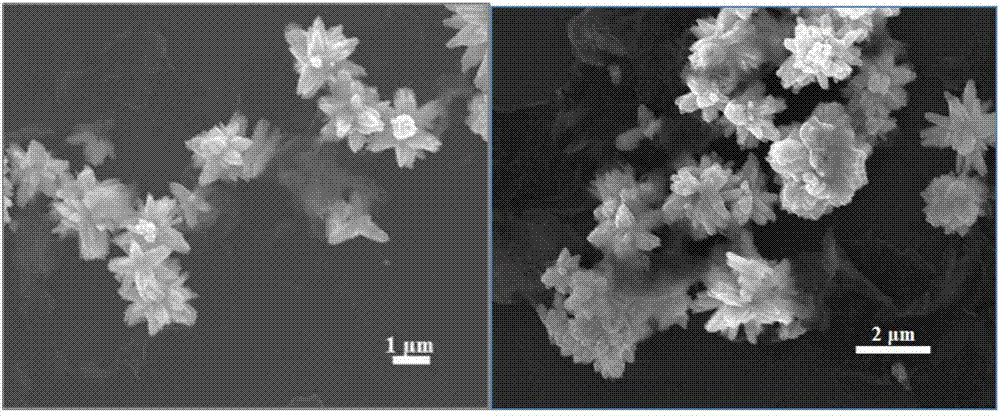

[0029] (4) Put the mixed solution in (3) into the reaction kettle, react at 160° C. for 12 hours, and wash and dry the flower-shaped ZnO catalyst.

[0030] (5) Weigh 0.05g of ZnO and ultrasonically disperse it in methanol solution for 20min, then add 0.015g of few-layer C ...

Embodiment 2

[0033] Embodiment 2: few layer C of the present invention 3 N 4 / ZnO photocatalyst degrades the application of methylene blue, specifically comprises the following steps: add 50mL MB solution (10mg / L) and 0.01g few-layer C simultaneously in the glass reaction vial 3 N 4 / ZnO catalyst, and then put it in a photoreaction apparatus, pass air in, and magnetically stir in a dark environment for 30 minutes to reach adsorption-desorption equilibrium, and turn on a 300W xenon lamp, and take 4mL solution every 30 minutes and place it in a test tube. Centrifuge and take the supernatant. Use an ultraviolet spectrophotometer (UV-2450) to measure at 663nm and record the data.

[0034] Figure 4 The few-layer C prepared for this example 3 N 4 Kinetic constant diagram of the degradation of methylene blue solution with a concentration of 10 mg / L by / ZnO composite photocatalyst under visible light. As can be seen from the figure, it can be found in the figure that each catalyst exhibits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com