Method for hydrothermally synthesizing nano-Au with polyacrylic acid

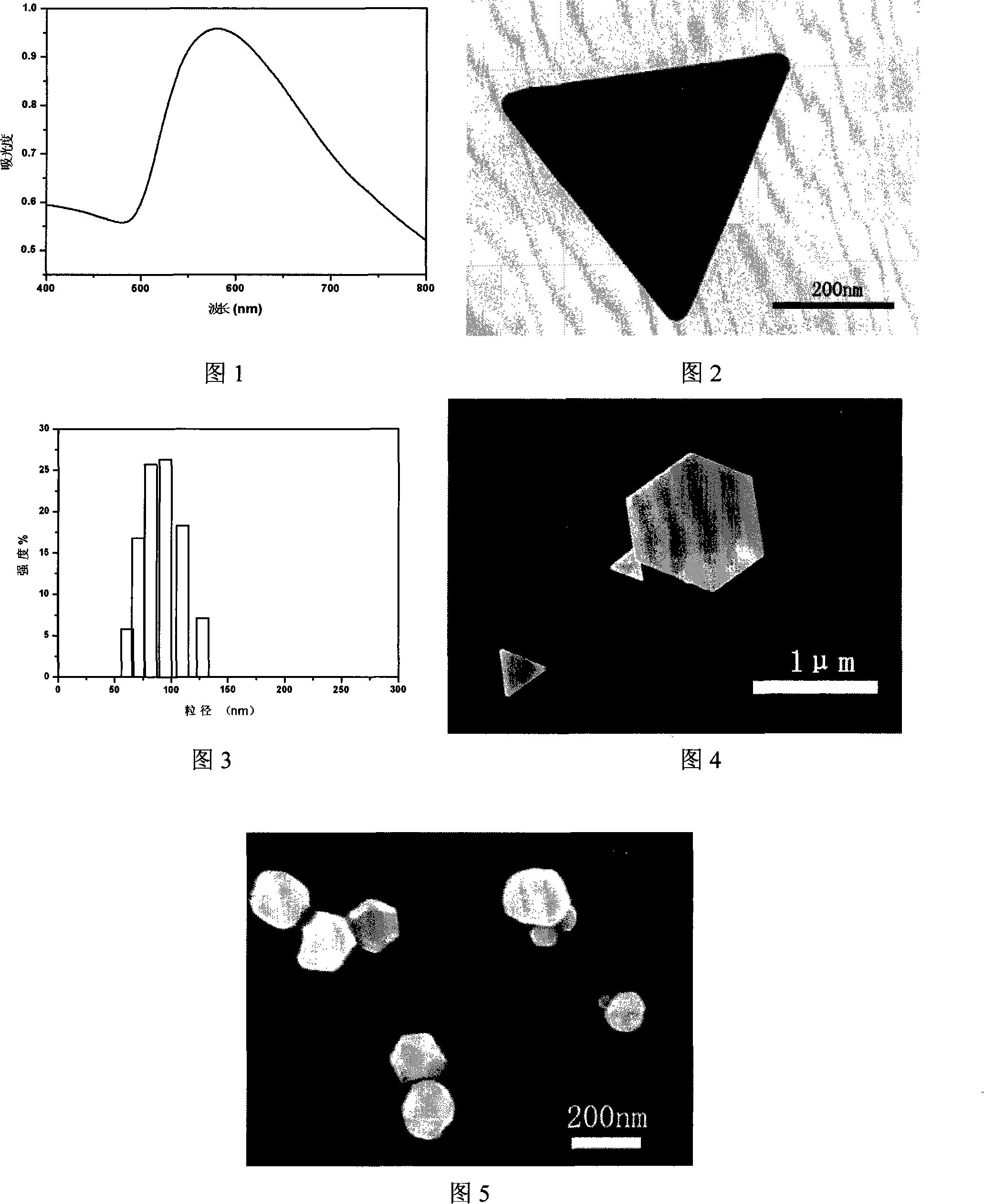

A technology of polyacrylic acid and hydrothermal synthesis, which is applied in the field of nano-gold, which can solve the problems of wide particle size distribution, difficulty in controlling the size and shape of metal nanoparticles, and achieve the effects of narrow particle size distribution, uniform shape, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 0.036 g of polyacrylic acid (molecular weight: 25000), dissolve it in 27 mL of water, and stir evenly; add 3 mL of chloroauric acid solution (0.01 M), and stir for 10 min to obtain a reaction precursor solution; pour the reaction precursor solution into polytetrafluoroethylene lined and loaded into an autoclave. After sealing, place it in an oven at 180°C for 4 hours; cool the reaction system to room temperature. The synthesized gold nanoparticles were separated from polyacrylic acid by centrifugation, and washed three times with ethanol. The obtained gold nanoparticles have a particle size of about 250 nm.

Embodiment 2

[0026] Take 0.144g sodium polyacrylate (molecular weight is 100000), dissolve in 28mL water, stir well; add 2mL chloroauric acid solution (0.01 M), stir for 10min, get the reaction precursor solution; pour the reaction precursor solution into polytetrafluoroethylene Vinyl lined and loaded into an autoclave. After sealing, place it in an oven at 140°C for 4 hours; cool the reaction system to room temperature. The synthesized gold nanoparticles were separated from sodium polyacrylate by centrifugation, and washed three times with ethanol. The particle size of the obtained gold nanoparticles is 150nm, and the size of the obtained gold nanosheets is 400nm and the thickness is 30nm.

Embodiment 3

[0028] Take 0.072g of polyacrylic acid (molecular weight: 240000), dissolve it in 29mL of water, and stir evenly; add 1mL of chloroauric acid solution (0.01M), and stir for 10min to obtain a reaction precursor solution; pour the reaction precursor solution into polytetrafluoroethylene lined and loaded into an autoclave. After sealing, place it in an oven at 200°C for 40 minutes; cool the reaction system to room temperature. The synthesized gold nanoparticles were separated from polyacrylic acid by centrifugation, and washed three times with ethanol. The obtained gold nanoparticles have a particle size of 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com