Manganese dioxide composite material, and preparation method and application thereof

A technology of manganese dioxide and composite materials, applied in the field of materials, can solve problems such as low conversion rate, limited practical application, and unsatisfactory conversion rate, and achieve the effects of easy operation, good application prospects, and accelerated catalytic oxidation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention further provides a preparation method of manganese dioxide composite material, comprising:

[0047] S1, providing permanganate, a saccharide compound and a solvent in which both the permanganate and the saccharide compound can be dissolved; and

[0048] S2, mixing the permanganate, the saccharide compound and the solvent to form a reaction solution, and reacting the reaction solution at 40°C to 100°C to obtain the manganese dioxide composite material.

[0049] In step S1, the permanganate may include at least one of potassium permanganate, sodium permanganate, calcium permanganate, lithium permanganate, barium permanganate, zinc permanganate and magnesium permanganate A sort of. Preferably, the permanganate may be at least one of potassium permanganate, sodium permanganate and calcium permanganate. More preferably, the permanganate may be potassium permanganate.

[0050] The saccharide compound may be at least one of monosaccharides, disaccharid...

Embodiment 1

[0065] Weigh 1.2g of potassium permanganate and dissolve it in an Erlenmeyer flask containing 100mL of water, then weigh 0.18g of glucose and add it to the above solution, and place the Erlenmeyer flask containing the reaction solution in a water bath at 80°C for 15 minutes to react. After the reaction, the solid in the Erlenmeyer flask was centrifugally washed, dried at 105° C. for 12 h, and ground to obtain manganese dioxide composite material powder (GLC-MnO 2 ).

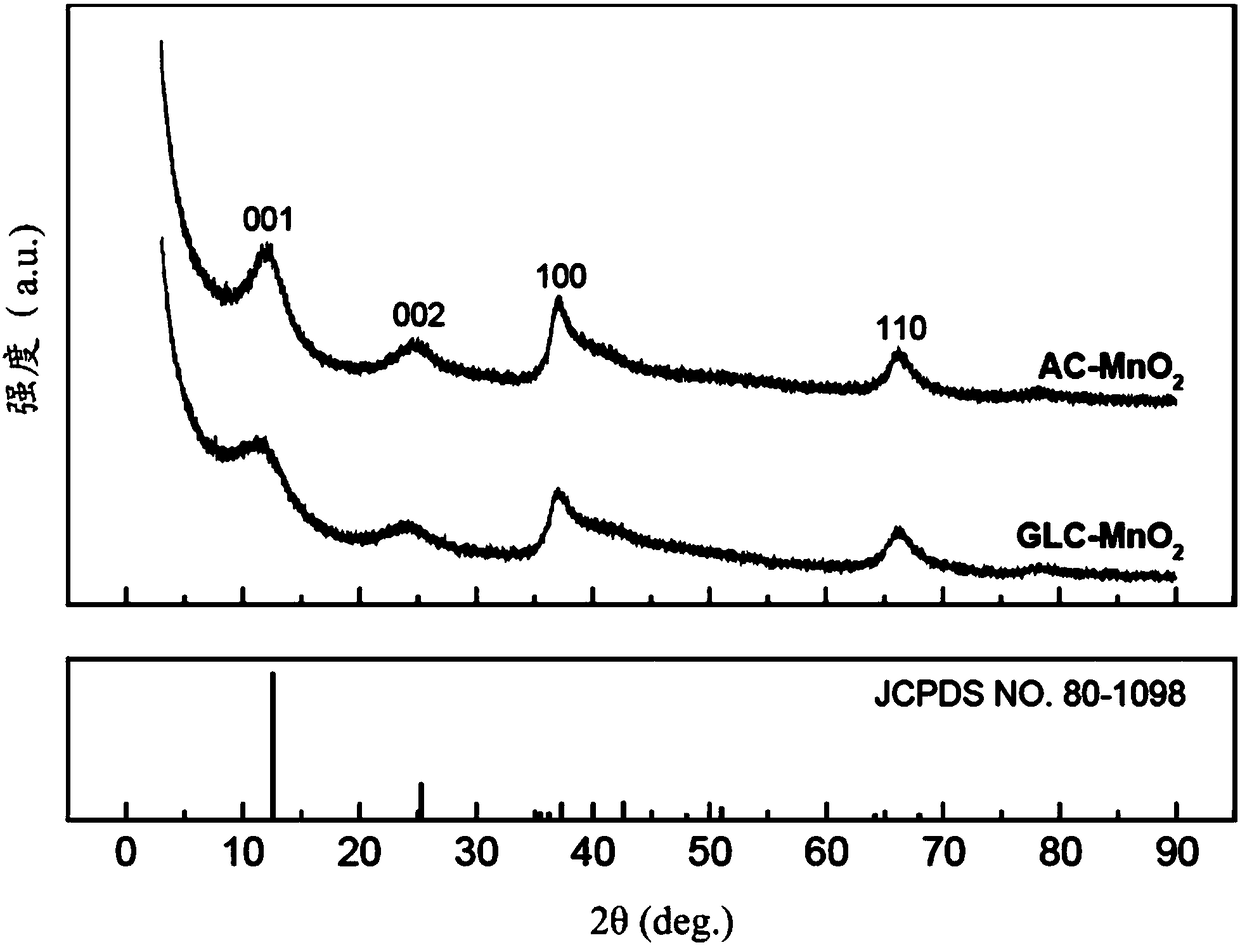

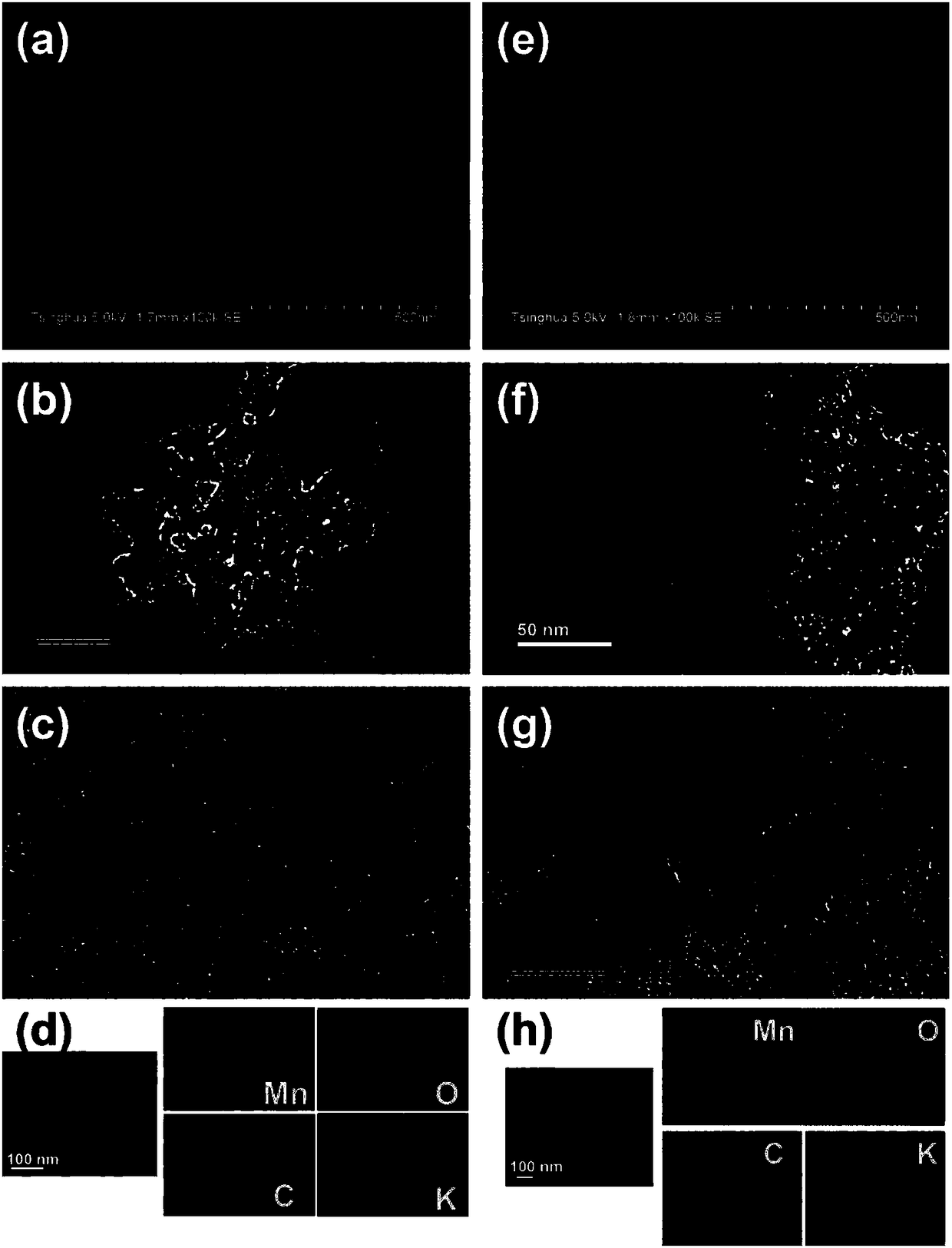

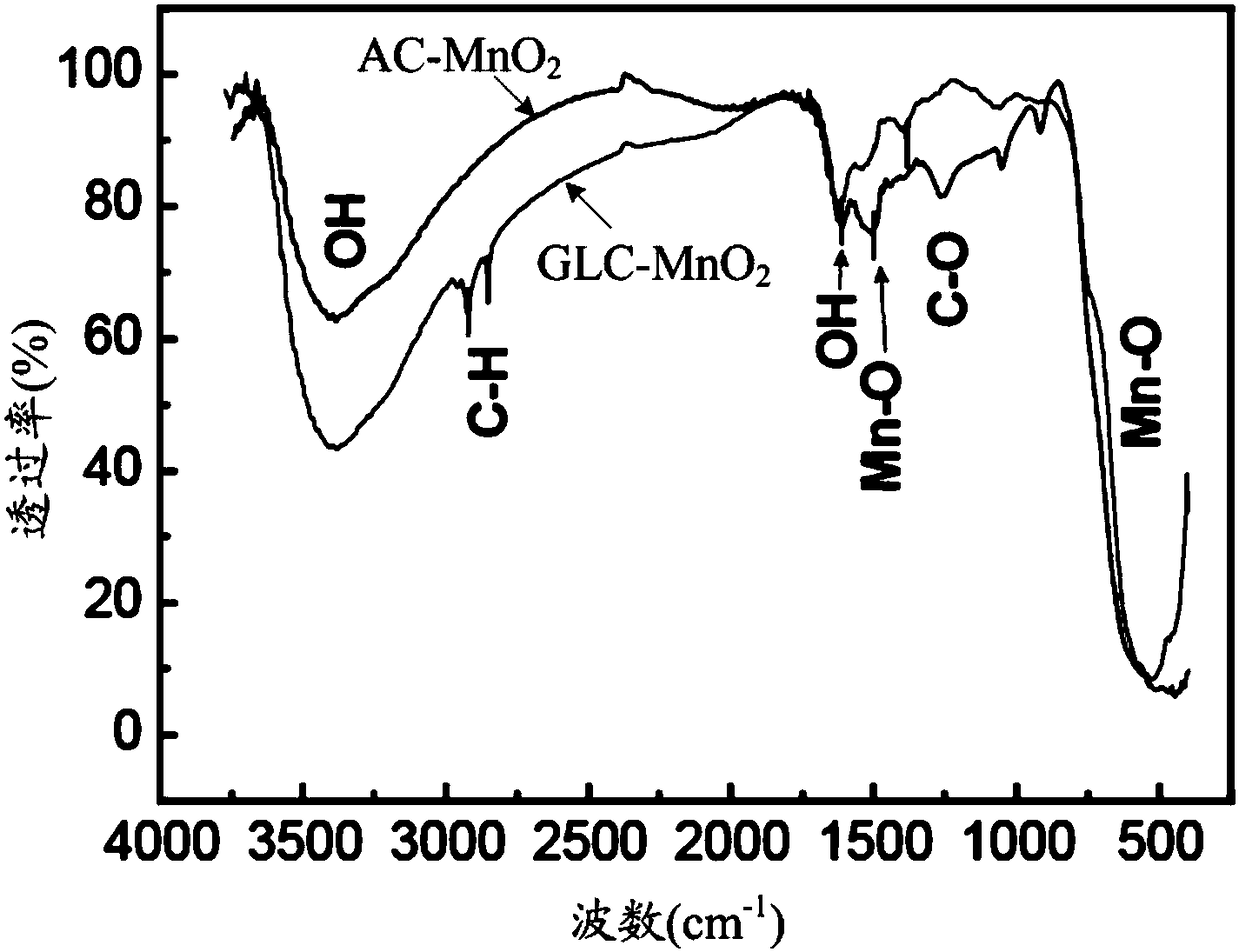

[0066] For the GLC-MnO 2 Characterize the performance, the results are as follows Figure 1 to Figure 6 and shown in Table 1.

[0067] Static degradation test of formaldehyde:

[0068] Weigh GLC-MnO 2 100mg, placed in the plexiglass reactor of 3.5L, and described catalyzer is sealed with airtight lid, pours a certain amount of formaldehyde into the plexiglass reactor, makes the formaldehyde concentration after equilibrium be about 200ppm. Open the sealing cover, make the catalyst and formaldehyde contact eac...

Embodiment 2

[0075] Weigh 1.2g of potassium permanganate and dissolve it in an Erlenmeyer flask containing 100mL of water, then weigh 0.34g of sucrose and add it to the above solution, and place the Erlenmeyer flask containing the reaction solution in a water bath at 80°C for 15min. After the reaction, the solid in the Erlenmeyer flask was centrifugally washed, dried at 105° C. for 12 h, and ground to obtain manganese dioxide composite material powder (AC-MnO 2 ).

[0076] For the AC-MnO 2 Characterize the performance, the results are as follows Figure 1 to Figure 6 and shown in Table 1.

[0077] Adopt the method identical with embodiment 1 to carry out the static degradation test of formaldehyde, the result is as follows Figure 7 shown.

[0078] Adopt the method identical with embodiment 1 under 55% relative humidity, formaldehyde initial concentration is 1.0mg / m 3 Carry out the dynamic degradation test of formaldehyde under the condition of condition, the result is as follows Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com