Graphene powder and preparation method thereof

A technology of graphene powder and graphite, which is applied in the field of graphene powder and its preparation, can solve the problems of unfavorable large-scale production of graphene powder, high energy consumption, and low efficiency, and achieve low lamellar stacking degree and high dispersion Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

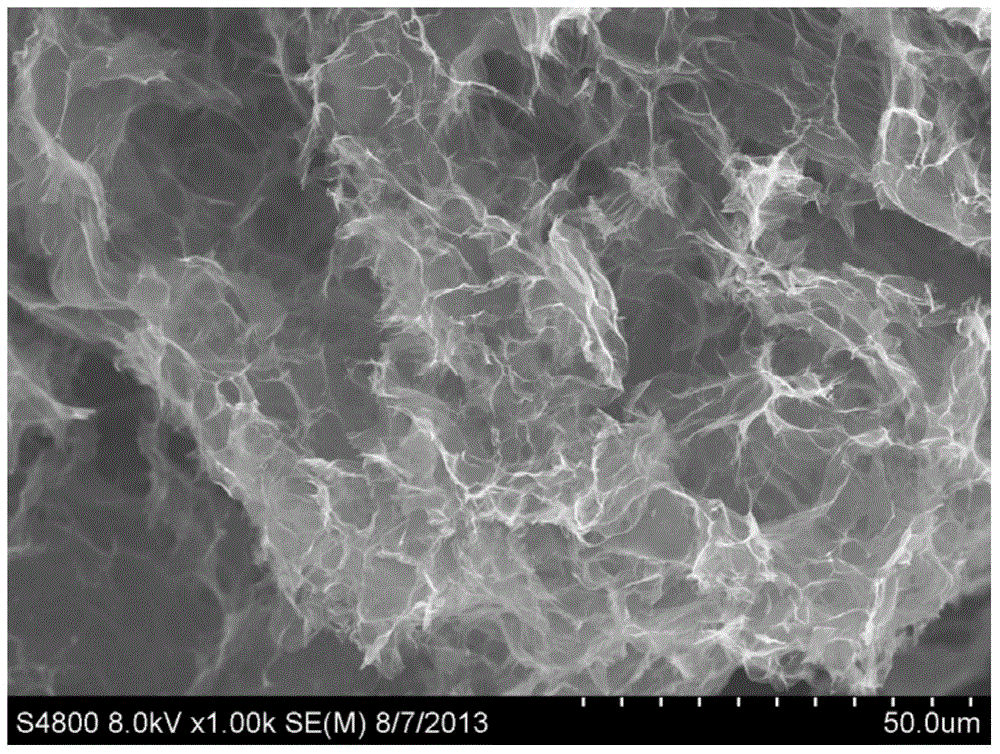

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of graphene powder, comprises the following steps:

[0031] a, graphite oxide is reacted with a dispersant to obtain an intermediate product, and the dispersant includes an ammonium salt;

[0032] b. Heat-treating the intermediate product to obtain graphene powder.

[0033] In the present invention, the dispersant can reduce the moisture content in the graphite oxide, avoid the strong capillary force generated by the graphene oxide sheets in the dehydration process, and weaken the degree of close contact between the graphene oxide sheets, making the present invention The degree of agglomeration of the obtained graphene powder is lower and the dispersibility is better; and the dispersant in the present invention is thermally decomposed in the process of heat treatment to produce a large amount of gas, and the gas produced can peel off graphite oxide, further weakening the present invention. The degree of agglomeration ...

Embodiment 1

[0061] Under the condition of stirring, 10 g of natural graphite with a particle size of 2 μm and 200 mL of fuming nitric acid were first mixed, 100 g of sodium chlorate was added to the obtained mixture, and oxidation reaction was carried out at 60° C. for 96 hours to obtain a reaction solution.

[0062] After the above reaction solution was left to stand for 24 hours, sodium carbonate was added to the reaction solution to make the pH of the reaction solution 11, and the reaction product in the reaction solution was flocculated to obtain graphite oxide.

[0063] After the above-mentioned graphite oxide was washed with water until neutral, the graphite oxide and ammonium bicarbonate were dispersed in water at a mass ratio of 1:1, and then reacted at 15°C for 24 hours to obtain an intermediate product. The above intermediate product was dried at 40° C. for 96 hours under vacuum conditions to obtain a pre-dried product; the pre-dried product was heat-treated at 80° C. for 30 min ...

Embodiment 2

[0066] Graphite oxide with a particle size of 100 μm and ammonium carbonate were dispersed in water at a mass ratio of 1:10, and then reacted at 40° C. for 96 hours to obtain an intermediate product.

[0067]The above intermediate product was dried at 80° C. for 12 hours under vacuum conditions to obtain a pre-dried product; the pre-dried product was heat-treated at 800° C. for 0.5 min to obtain graphene powder. According to the method described in Example 1, the dispersibility and carbon-oxygen mass ratio of the graphene powder obtained in Example 2 are detected, and the test result is that the layer stacking degree of the graphene powder obtained in Embodiment 2 of the present invention is relatively low. Low, good dispersion, the carbon to oxygen mass ratio of graphene powder is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com