Positive material for lithium ion battery, preparation method of material, and lithium ion battery

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of LiMnPO4 electrochemical performance to be improved, and achieve high specific energy, performance improvement, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of lithium-ion battery cathode material, comprises the following steps:

[0031] a) providing nano-lithium phosphate, the nano-lithium phosphate has a hollow structure;

[0032] b) Mix the nano-lithium phosphate, soluble manganese source compound, additives, water and polyalcohol mixed solvent provided in step a) and then ball mill to obtain a mixed solution, and then put the mixed solution in an inert gas-closed In the reaction kettle, heat preservation is carried out at a temperature of 150°C to 230°C to obtain lithium manganese phosphate;

[0033] c) mixing the lithium manganese phosphate obtained in the step b) with a carbon source compound, ball milling, and calcining to obtain a positive electrode material for a lithium ion battery with carbon-coated lithium manganese phosphate.

[0034]The preparation method of lithium manganese phosphate lithium ion battery cathode material provided by the present invention is...

Embodiment 1

[0072] The concentration is 2.5mol·L -1 LiOH·H 2 Add the O solution into the stirring reaction device, stir at a speed of 600rpm until the pH is stable, and then pass the peristaltic pump to a concentration of 1.1mol L -1 of phosphoric acid (H 3 PO 4 ) solution was added to the stirring reaction device at a feeding rate of 0.8mL / min for reaction, wherein, LiOH·H 2 O and H 3 PO 4 The molar ratio of the phosphoric acid solution is 3:1. After the phosphoric acid solution is added, it is stirred at a speed of 300rpm for 30min, and the reaction generates a precipitate. The precipitate is washed, suction filtered and dried to obtain white Li 3 PO 4 powder.

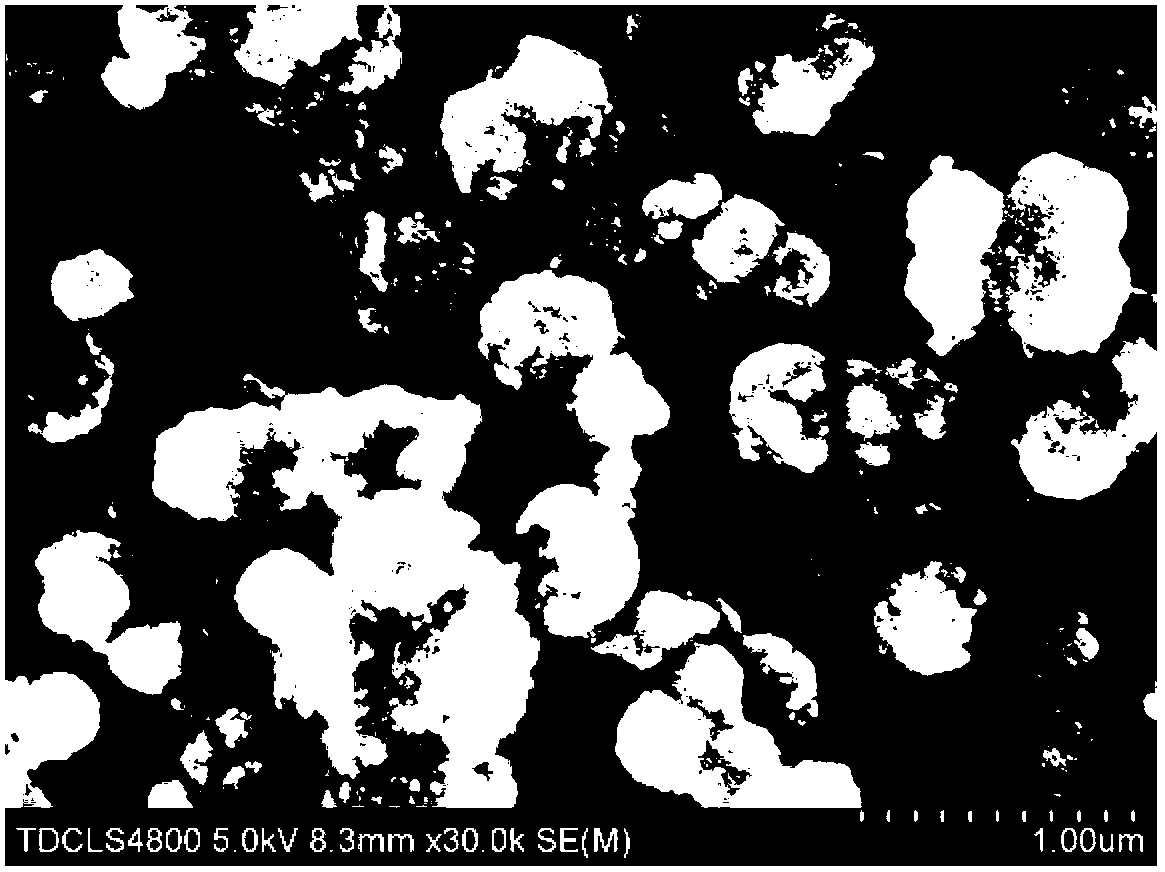

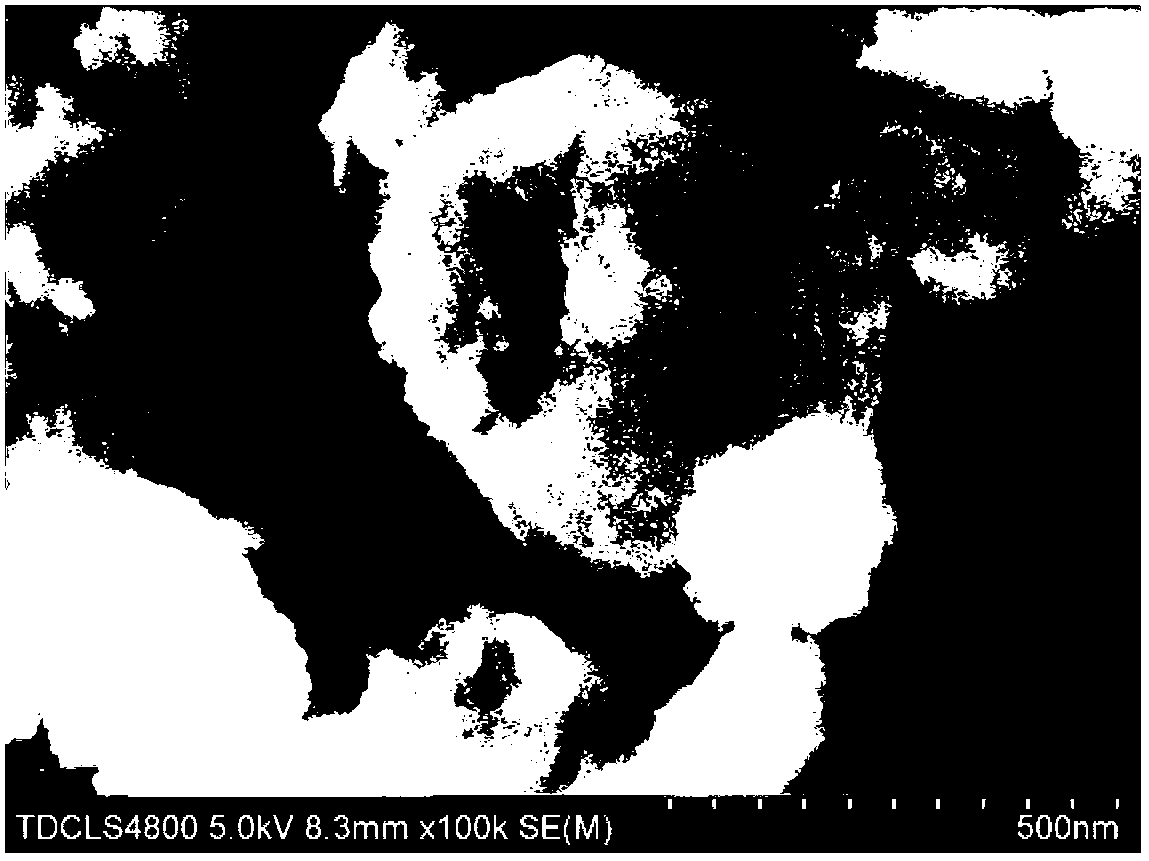

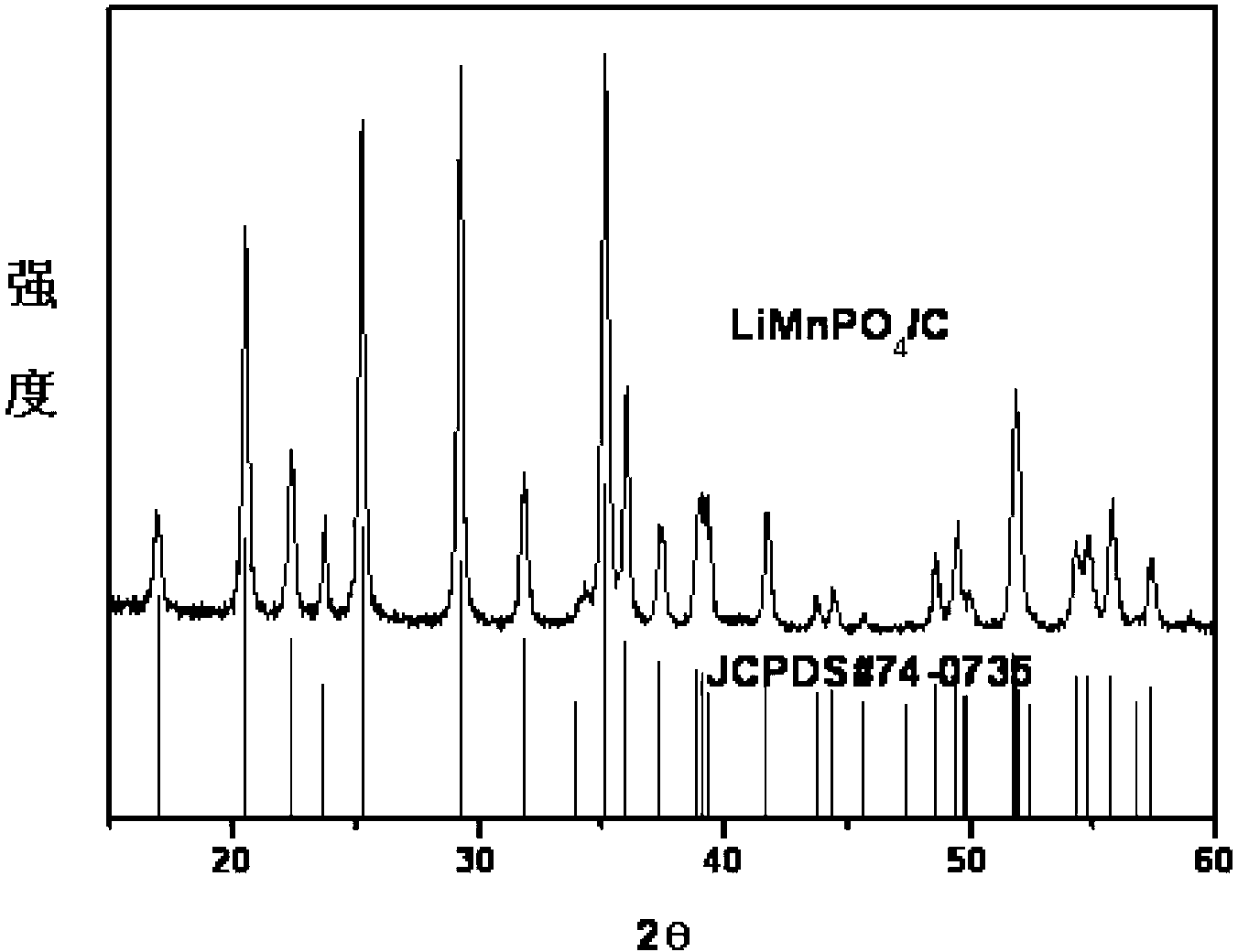

[0073] will get Li 3 PO 4 The powder was analyzed by SEM, the results can be found in figure 1 and figure 2 , figure 1 For the Li obtained in Example 1 of the present invention 3 PO 4 SEM image at 30.0k, figure 2 For the Li obtained in Example 1 of the present invention 3 PO 4 SEM image at 100k. Depend on fi...

Embodiment 2

[0080] The concentration is 2.5mol·L -1 LiOH·H 2 Add the O solution into the stirring reaction device, stir at a speed of 600rpm until the pH is stable, and then pass the peristaltic pump to a concentration of 1.1mol L -1 LiH 2 PO 4 The solution was added into the stirring reaction device at a feeding rate of 0.8mL / min for reaction, wherein, LiOH·H 2 O and LiH 2 PO 4 The molar ratio of LiH is 2:1, when LiH 2 PO 4 After the solution was added, it was stirred at a speed of 300rpm for 30min, and a precipitate was formed in the reaction, which was washed, filtered and dried to obtain white Li 3 PO 4 powder.

[0081] According to the molar ratio of 1:1, the Li 3 PO 4 Powder and MnCl 2 Transfer to a polyurethane ball mill tank, add 0.45g of ascorbic acid, and then add 60mL of a mixed solvent composed of water and 1,4-butanediol, wherein the molar ratio of the water to 1,4-butanediol is 200, and carry out liquid phase Ball milled for 0.5h to obtain a mixed solution, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com