Method for hydro-thermally synthesizing MoS<2> nanoflower with sulfur-containing biological reagent as sulfur source

A biological reagent, hydrothermal synthesis technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as no public reports, achieve high chemical activity, simple separation and purification, and adsorption Powerful and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

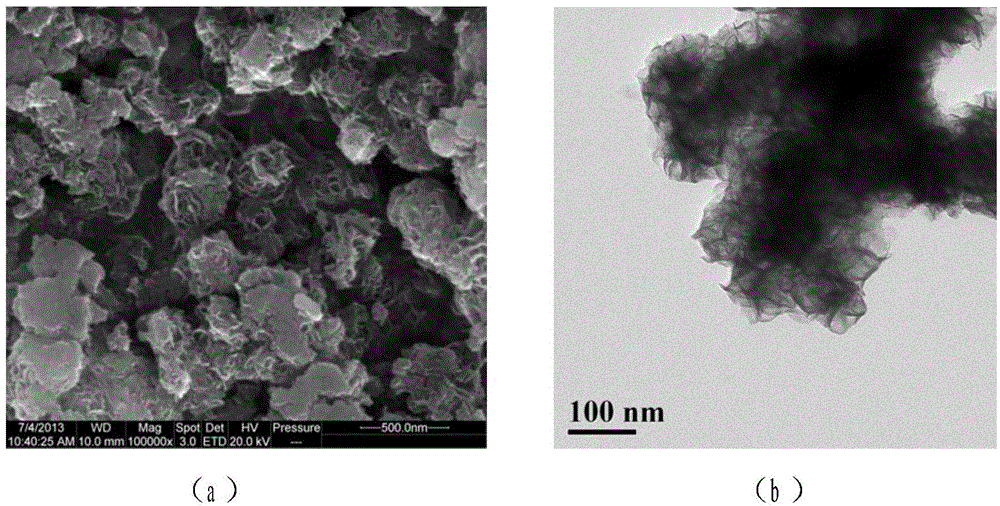

[0024]Weigh 1.5mmol of sodium molybdate, stir and dissolve it in 50ml of deionized water to form a 0.03M solution; add 3mmol of glutathione under stirring, and the pH of the resulting solution is 3; after fully stirring, transfer the solution to 100ml In a hydrothermal reaction kettle, conduct a hydrothermal reaction at 180°C for 18 hours. After natural cooling, filter with suction, wash the precipitate with deionized water and absolute ethanol, and then dry it under vacuum at 70°C overnight to obtain a black powder sample. XRD characterization results show that the obtained product is MoS 2 ;SEM characterization shows that the product is nanoscale MoS 2 The flower-like structure is formed by the accumulation of lamellar structure, and the dispersion is good.

Embodiment 2

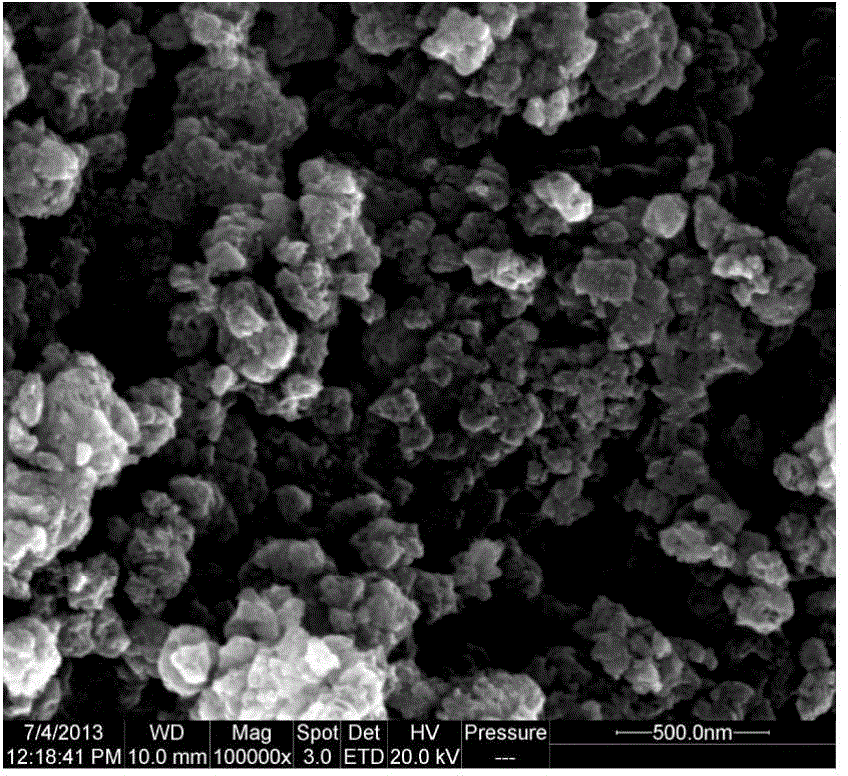

[0026] Weigh 0.22mmol of ammonium molybdate, stir and dissolve it in 50ml of deionized water to form a 0.0044M solution; add 4.62mmol of L-cysteine while stirring, and the pH of the resulting solution is 6; Transfer to a 100ml hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for 24 hours. After natural cooling, filter with suction, wash the precipitate with deionized water and absolute ethanol, and then dry it under vacuum at 70°C overnight to obtain a black powder sample. XRD characterization results show that the obtained product is MoS2; SEM characterization shows MoS 2 The surface of the microsphere is composed of a large number of sheet structures assembled in all directions, and each MoS 2 The size of the nanoflowers is about 300nm, which is different from the products prepared by common sulfur sources ( Figure 4 ) is better dispersed than ( figure 1 a); TEM characterization results show that the product is formed by cross-linking and stack...

Embodiment 3

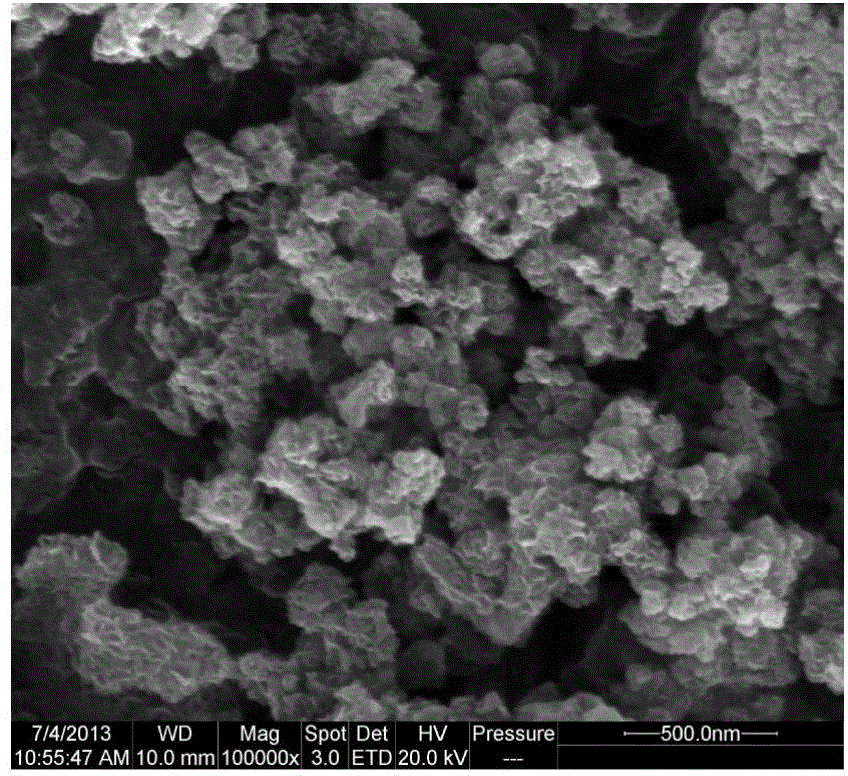

[0028] Weigh 0.22mmol of ammonium molybdate, stir and dissolve it in 50ml deionized water to form a 0.0044M solution; add 4.62mmol of L-cysteine while stirring; adjust the pH of the solution with concentrated hydrochloric acid with a mass concentration of 37.5% 1, the color of the solution changed from bright yellow to lake blue during this process; after fully stirring, the solution was transferred to a 100ml hydrothermal reaction kettle, and hydrothermally reacted at 200°C for 24 hours. After natural cooling, suction filtration was used to precipitate Washed with ionic water and absolute ethanol, and then dried under vacuum at 70 °C overnight to obtain a black powder sample. XRD characterization results show that the obtained product is MoS 2 ;SEM characterization shows that the product is about 100nm MoS 2 Nanoflowers are formed by stacking lamellar structures with good dispersion ( figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com