Stannic oxide/graphene carbon nitride composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and graphite carbon nitride, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Recombination efficiency, photocatalytic performance can not meet the requirements and other problems, to achieve the effect of simple operation, conducive to large-scale preparation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

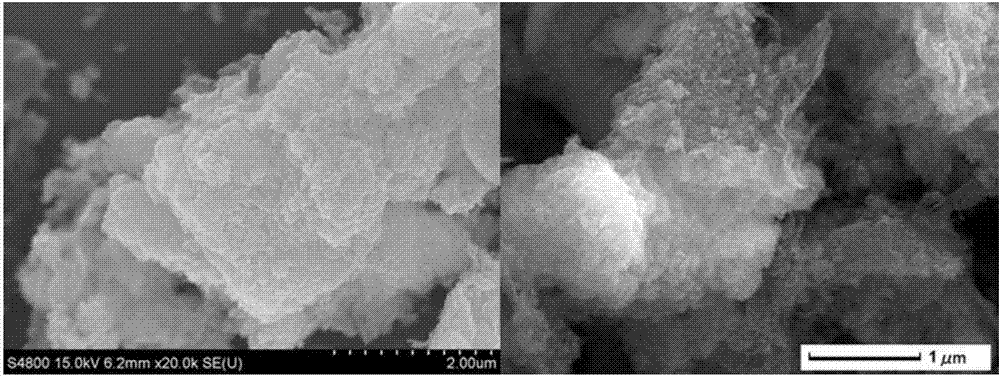

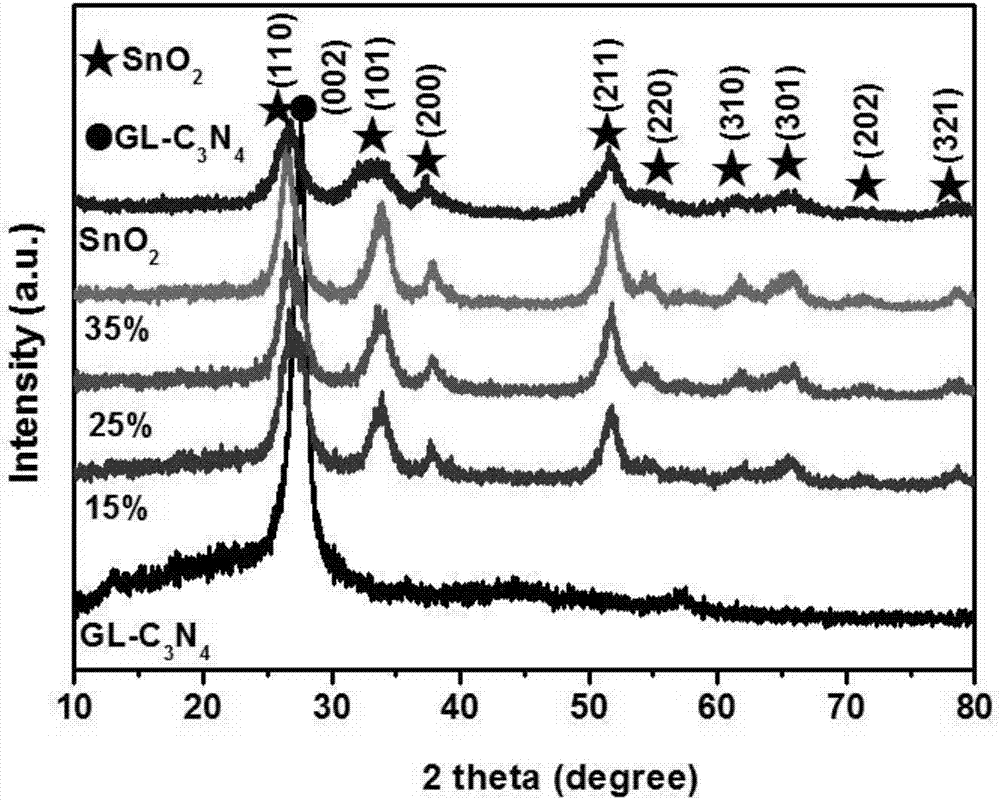

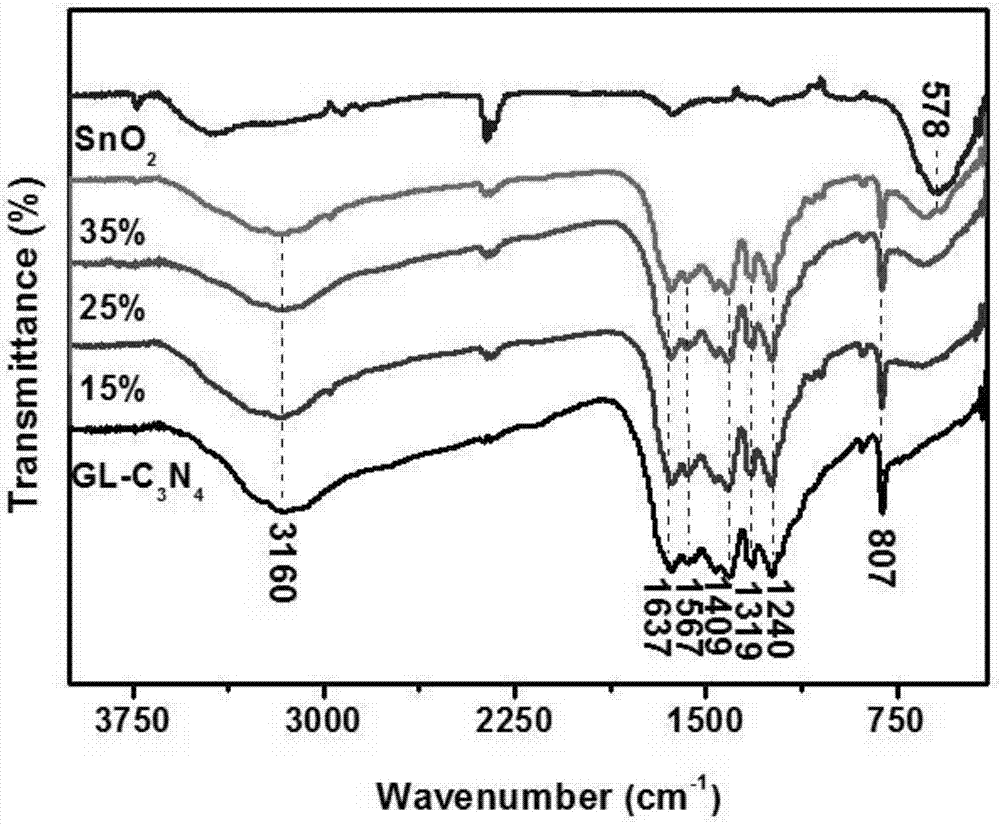

[0019] Embodiment 1: the present invention is a kind of preparation method of visible light response type tin dioxide / graphene-like carbon nitride (15wt%) composite photocatalyst, comprising the following steps:

[0020] (1) 6g of dicyandiamide was placed in a tube furnace, fed with nitrogen, and calcined at 600°C for 2 hours to obtain block graphite carbon nitride;

[0021] (2) Put 0.1426g of stannous chloride in a beaker, add deionized water and ethanol to ultrasonically disperse, after it is completely dissolved, adjust the pH to 11 with ammonia water, continue stirring for 10min, the volume of ammonia water is about 2.3mL, deionized The volumes of water and ethanol are both 20mL;

[0022] (3) Put the mixed solution in (2) into a reaction kettle, react at 120° C. for 6 hours, then cool rapidly, centrifuge the mixed solution and dry it in vacuum to obtain tin dioxide;

[0023] (4) Add 0.1 g of block graphite carbon nitride and 0.5 g of ammonium chloride to deionized water a...

Embodiment 2

[0027] Embodiment 2: the present invention is a kind of preparation method of visible light response type tin dioxide / graphene-like carbon nitride (25wt%) composite photocatalyst, comprising the following steps:

[0028] (1) Put 6g of dicyandiamide in a tube furnace, feed nitrogen, and calcinate at 600°C for 2h to obtain block graphite type C 3 N 4 ;

[0029] (2) Put 0.1426g of stannous chloride in a beaker, add deionized water and ethanol to ultrasonically disperse, after it is completely dissolved, adjust the pH to 11 with ammonia water, continue stirring for 10min, the volume of ammonia water is about 2.3mL, deionized The volumes of water and ethanol are both 20mL;

[0030] (3) Put the mixed solution in (2) into a reaction kettle, react at 120° C. for 6 hours, then cool rapidly, centrifuge the mixed solution and dry it in vacuum to obtain tin dioxide;

[0031] (4) Add 0.1 g of block graphite carbon nitride and 0.5 g of ammonium chloride to deionized water and ethanol sol...

Embodiment 3

[0035] Embodiment 3: the present invention is a kind of preparation method of visible light response type tin dioxide / graphene-like carbon nitride (35wt%) composite photocatalyst, comprising the following steps:

[0036] (1) Put 6g of dicyandiamide in a tube furnace, feed nitrogen, and calcinate at 600°C for 2h to obtain block graphite type C 3 N 4 ;

[0037] (2) Put 0.1426g of stannous chloride in a beaker, add deionized water and ethanol to ultrasonically disperse, after it is completely dissolved, adjust the pH to 11 with ammonia water, continue stirring for 10min, the volume of ammonia water is about 2.3mL, deionized The volumes of water and ethanol are both 20mL;

[0038] (3) Put the mixed solution in (2) into a reaction kettle, react at 120° C. for 6 hours, then cool rapidly, centrifuge the mixed solution and dry it in vacuum to obtain tin dioxide;

[0039] (4) Add 0.1 g of block graphite carbon nitride and 0.5 g of ammonium chloride to deionized water and ethanol solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com